Electrochemical process and device for hydrogen generation and storage

a technology of electrochemical process and hydrogen generation, applied in the direction of electrochemical generators, electrolysis components, electrolytic processes, etc., to achieve the effect of minimizing the extent of hydrogen transport and expanding hydrogen transpor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

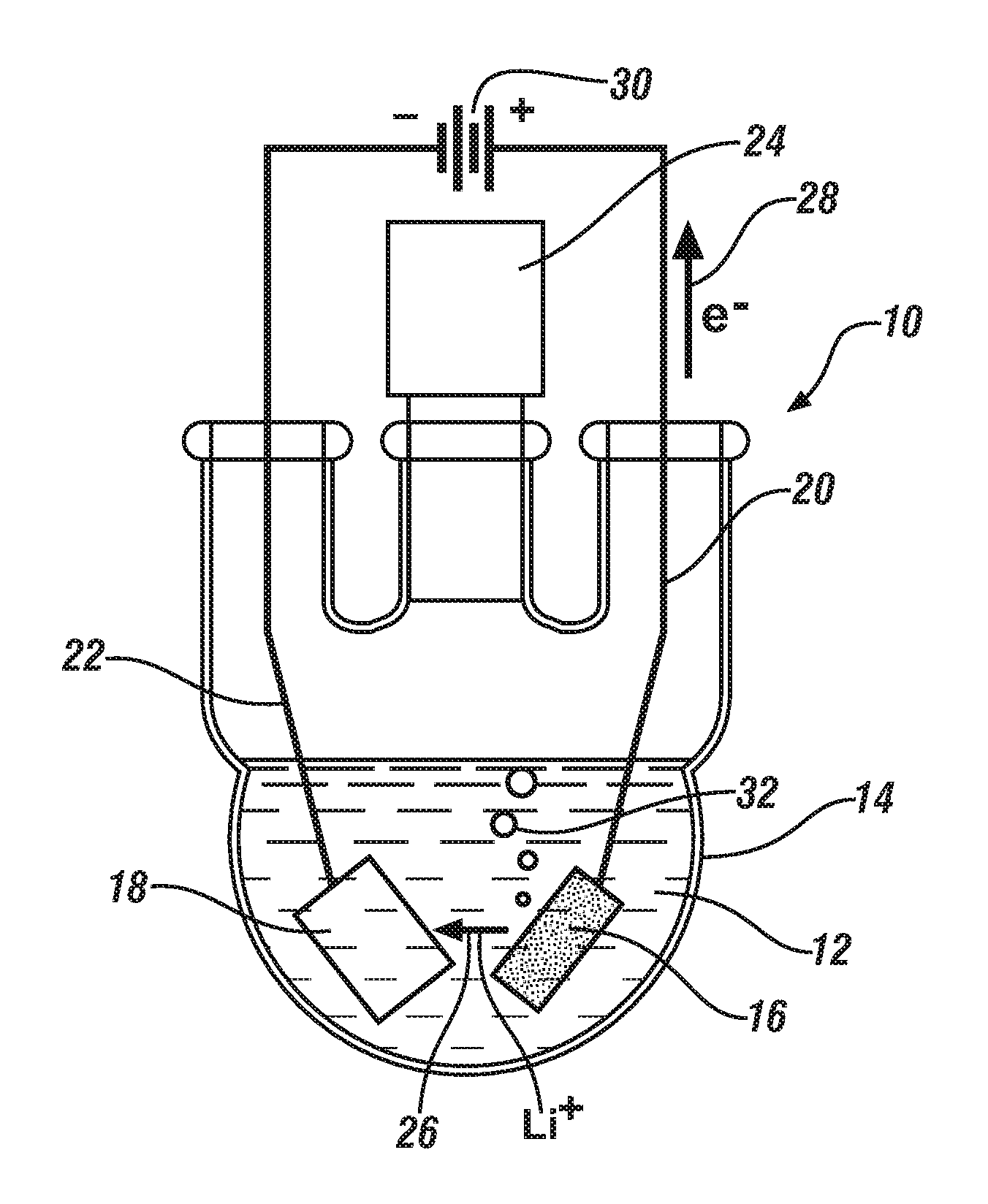

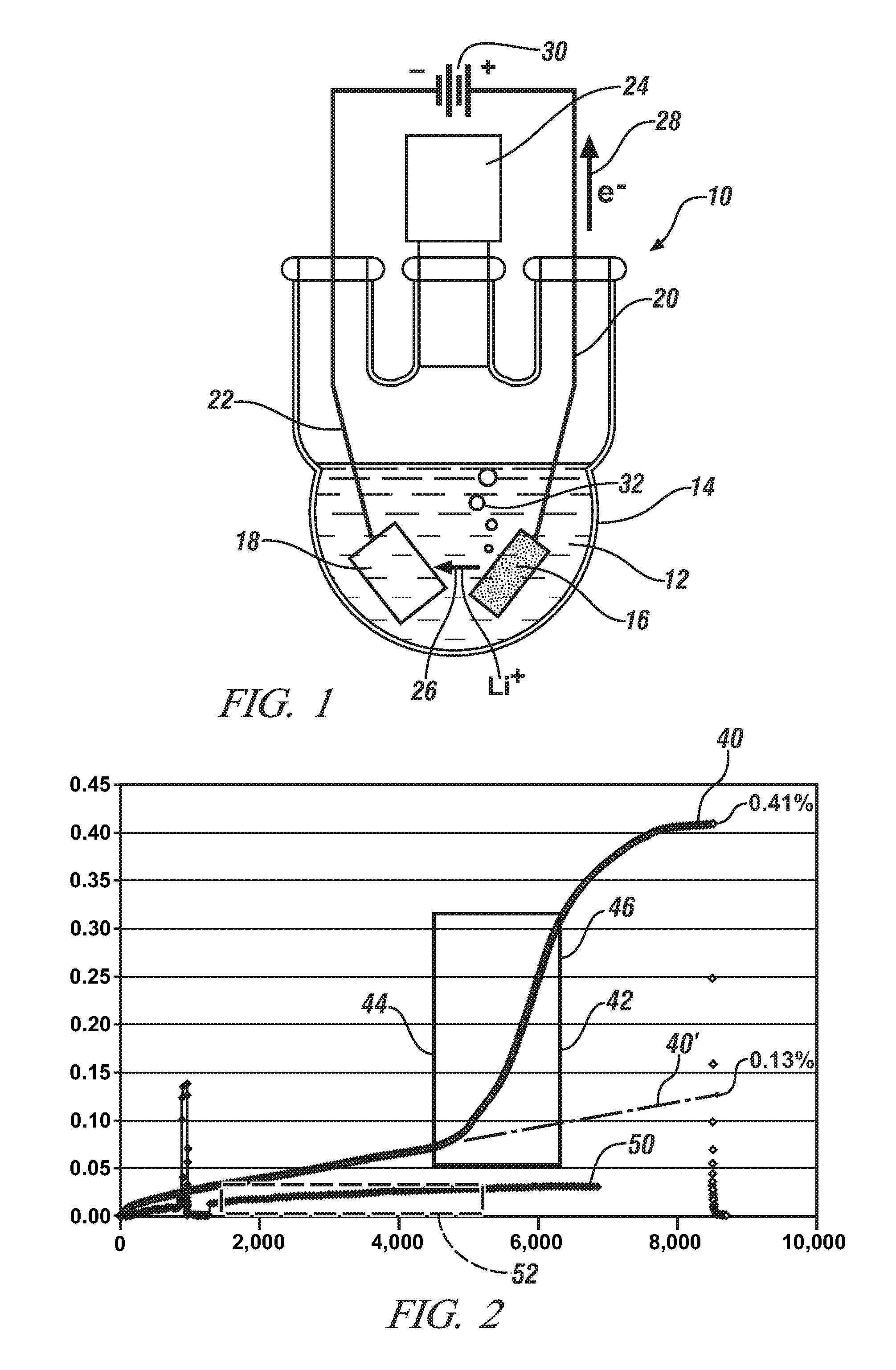

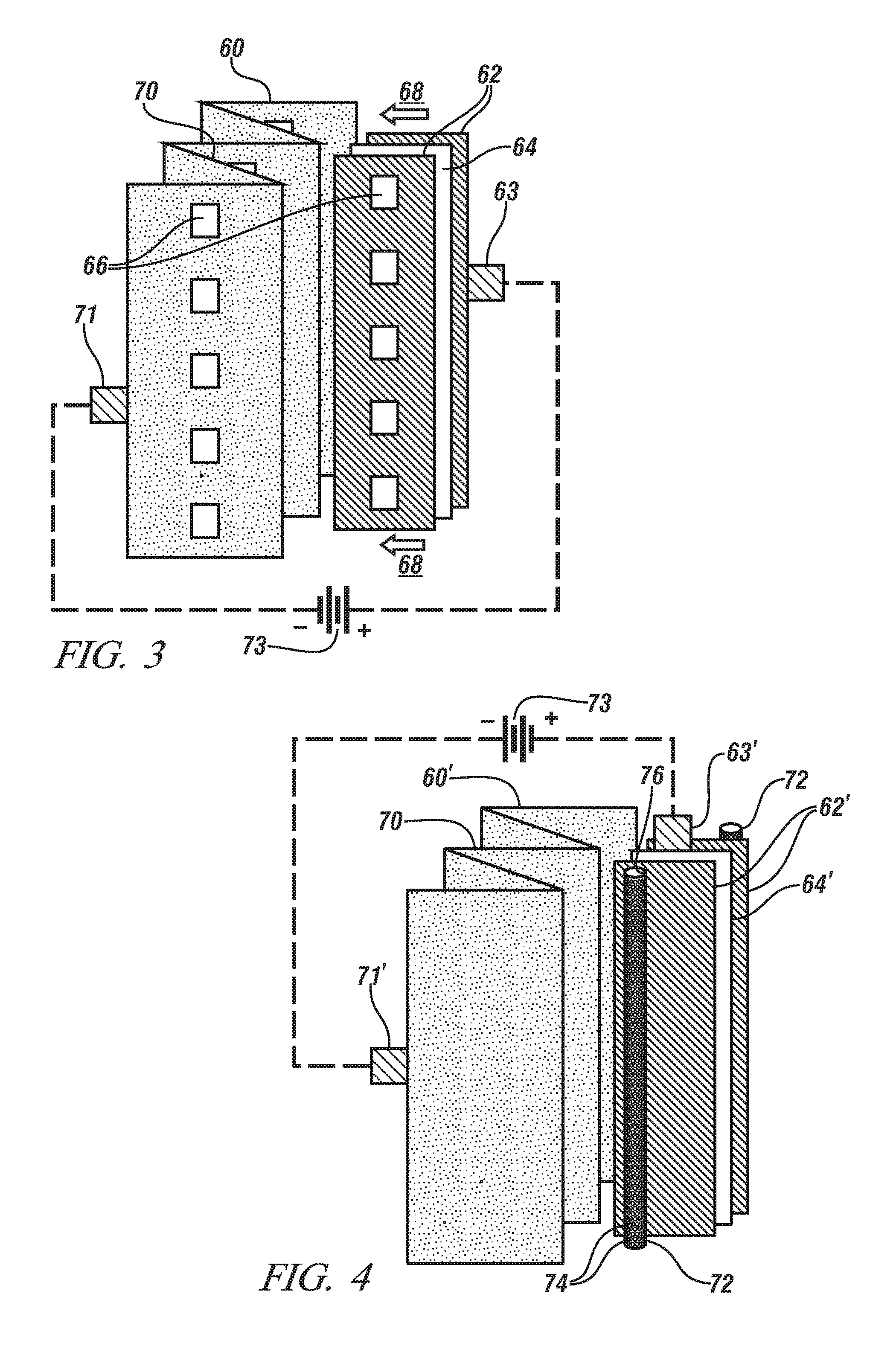

[0032]The following description of the embodiment(s) is merely exemplary in nature and is not intended to limit the invention, its application, or uses.

[0033]In vehicle applications, chemical storage and release of hydrogen using metal hydrides appears to be an attractive alternative to physical storage of hydrogen which may require one or more of, high pressures, or low temperatures or specially prepared substrates to be viable.

[0034]For example, most hydrides, in the absence of a stimulus, are stable at ambient and near-ambient temperatures of say 10-100° C. so that they may be stored without need for low temperature or high pressure. The volume of hydrogen produced may be changed incrementally by addition of more or less reagent to modify the available vehicle range or to satisfy the needs of vehicles of different sizes and use patterns. Chemical reactions for release of hydrogen may be reversed to regenerate and recharge a spent hydrogen source, either on-vehicle or with suitabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| atomic weights | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com