Surface mounted four terminal resistor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

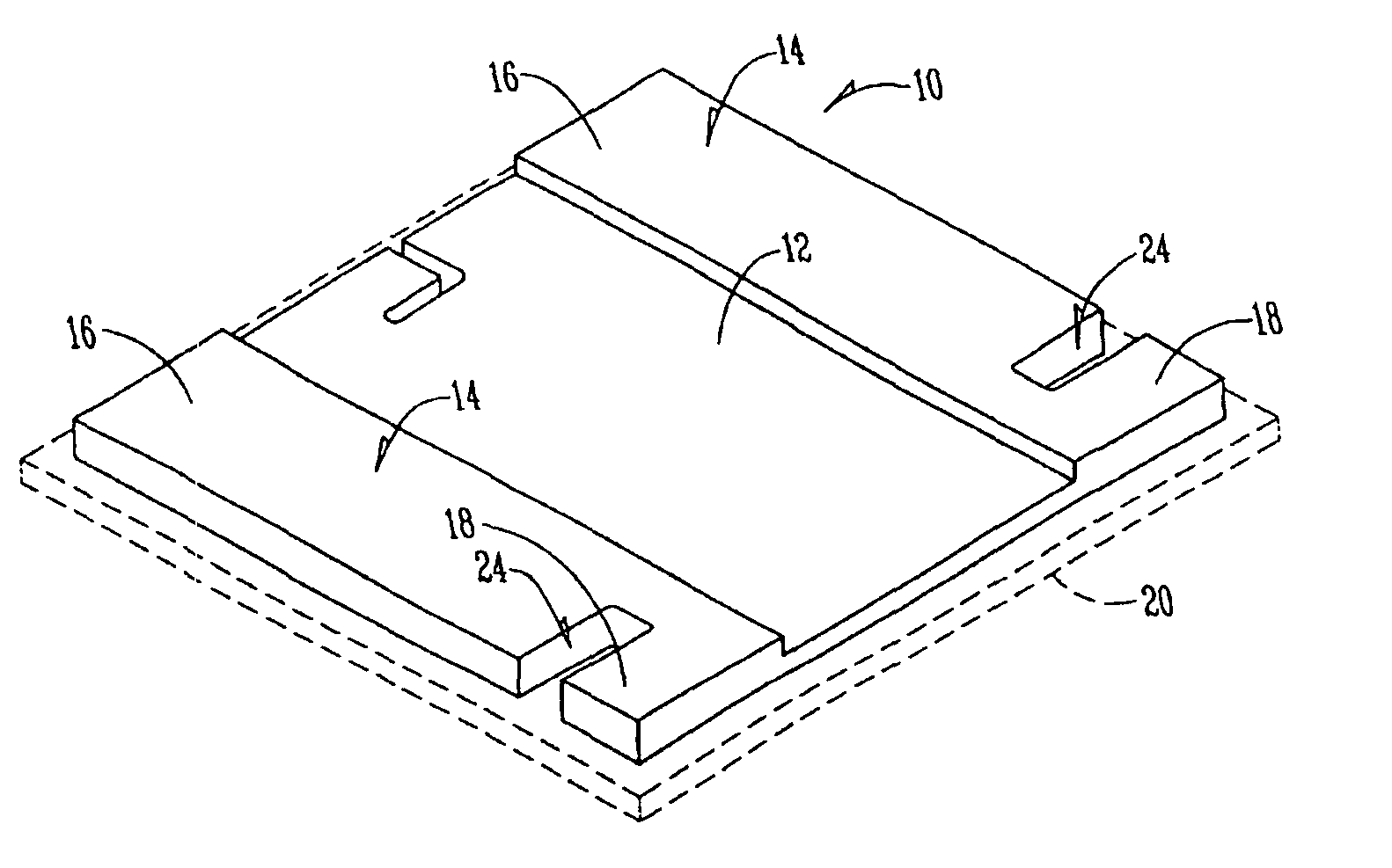

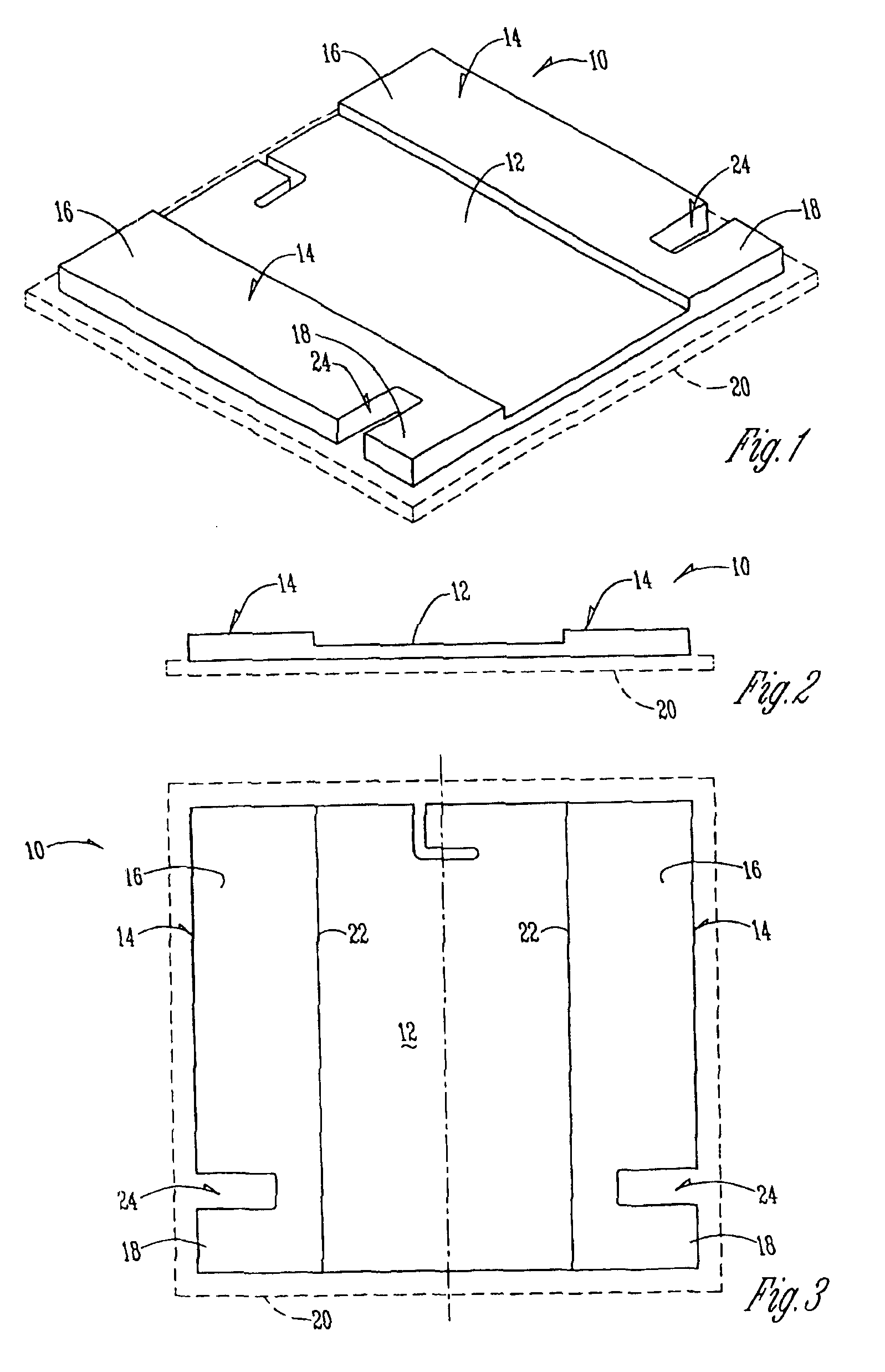

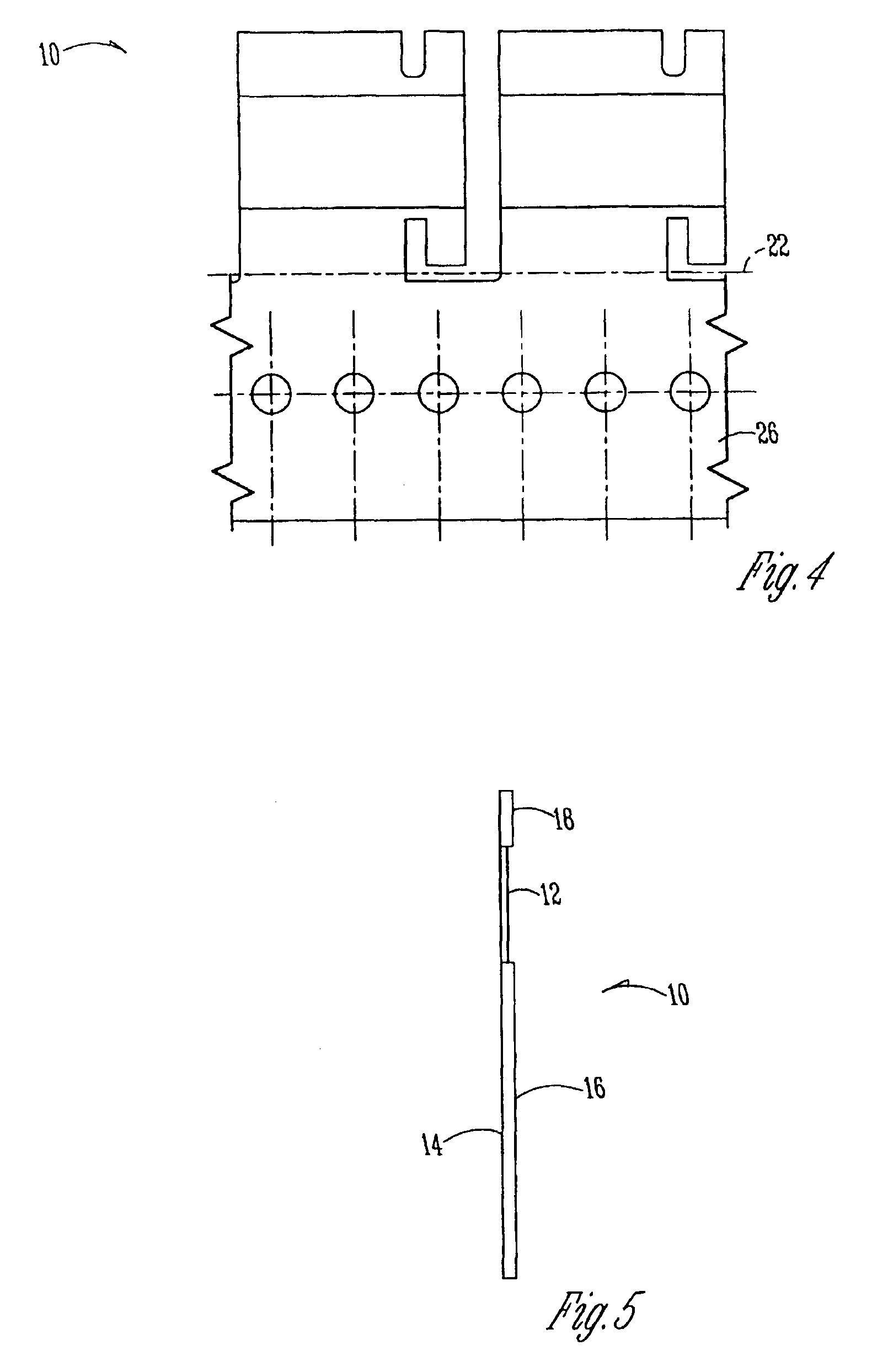

[0020]The numeral 10 designates the resistor of this invention. It includes a resistor plate 12 with a pair of pads 14 secured thereto. Each pad has a current pad portion 16 and a sense pad portion 18. Resistor 10 is adapted for mounting on substrate 20. Specifically, the surface mounted resistor 10 is formed by welding to each side of the resistive strip 12 of Ni—Cr alloy two strips 14, one narrow and another wide, of a Ni plated high conductivity copper. The thickness and width of the resistive strips 12 are chosen to form a resistance value below but close to the requested target, and therefore to minimize the extent of posterior laser trimming. This composite strip is punched on lines 22 (FIG. 4) to form individual resistors 10 in a way described in the U.S. Pat. No. 5,604,477 (incorporated herein by reference), but with an additional slot 24 in the terminations in order to divide them into distinct current and sense pads, the current pad 16 being at least twice as long as the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com