Multi piece turpocharger housing

a turpocharger and housing technology, applied in the direction of engine lubrication, motors, leakage prevention, etc., can solve the problems of premature ignition of the fuel-air mixture in the cold housing, large amount of friction energy released, and risk of sliding bearing damage, etc., to achieve simple and economical manufacturing, light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

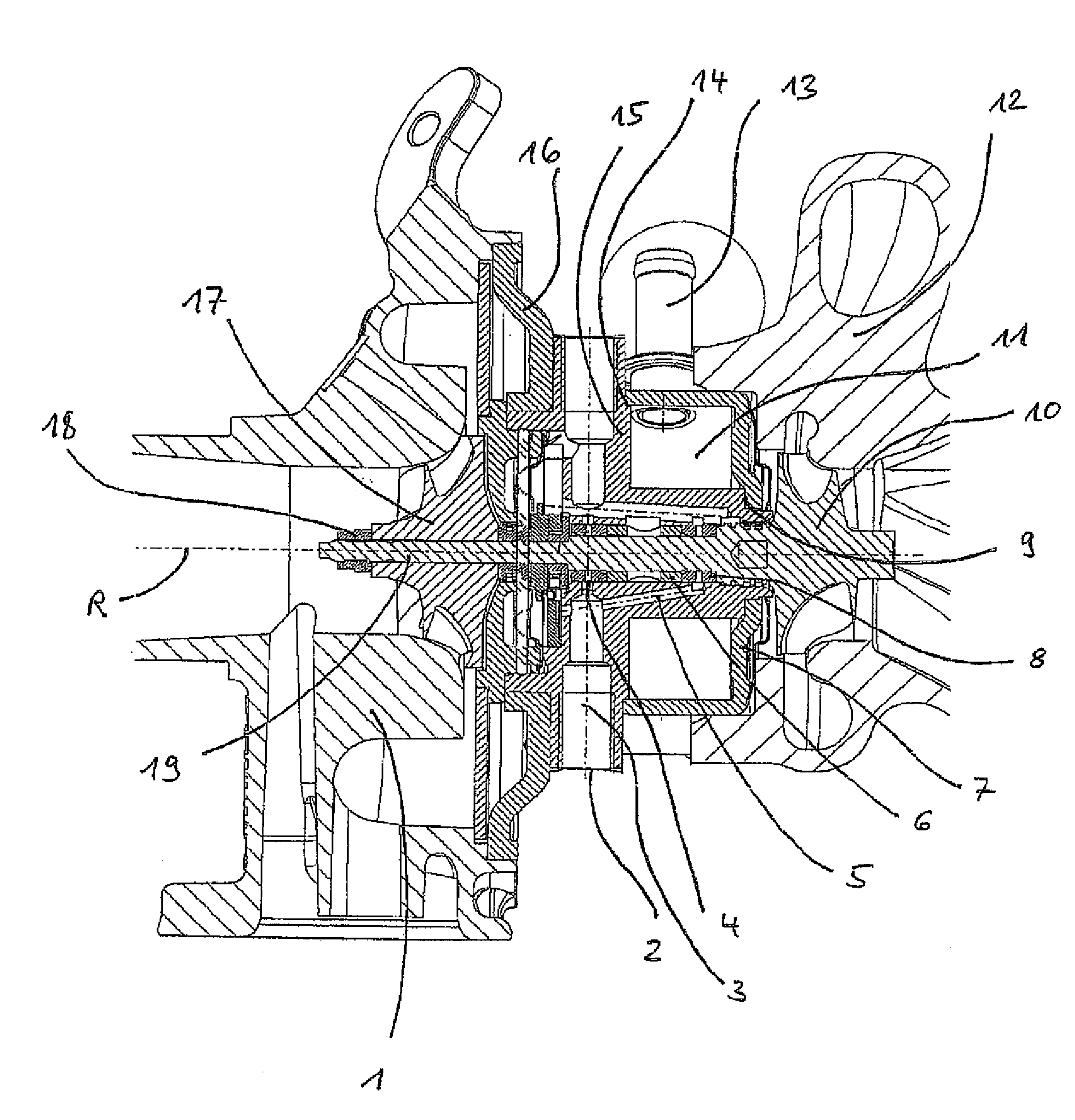

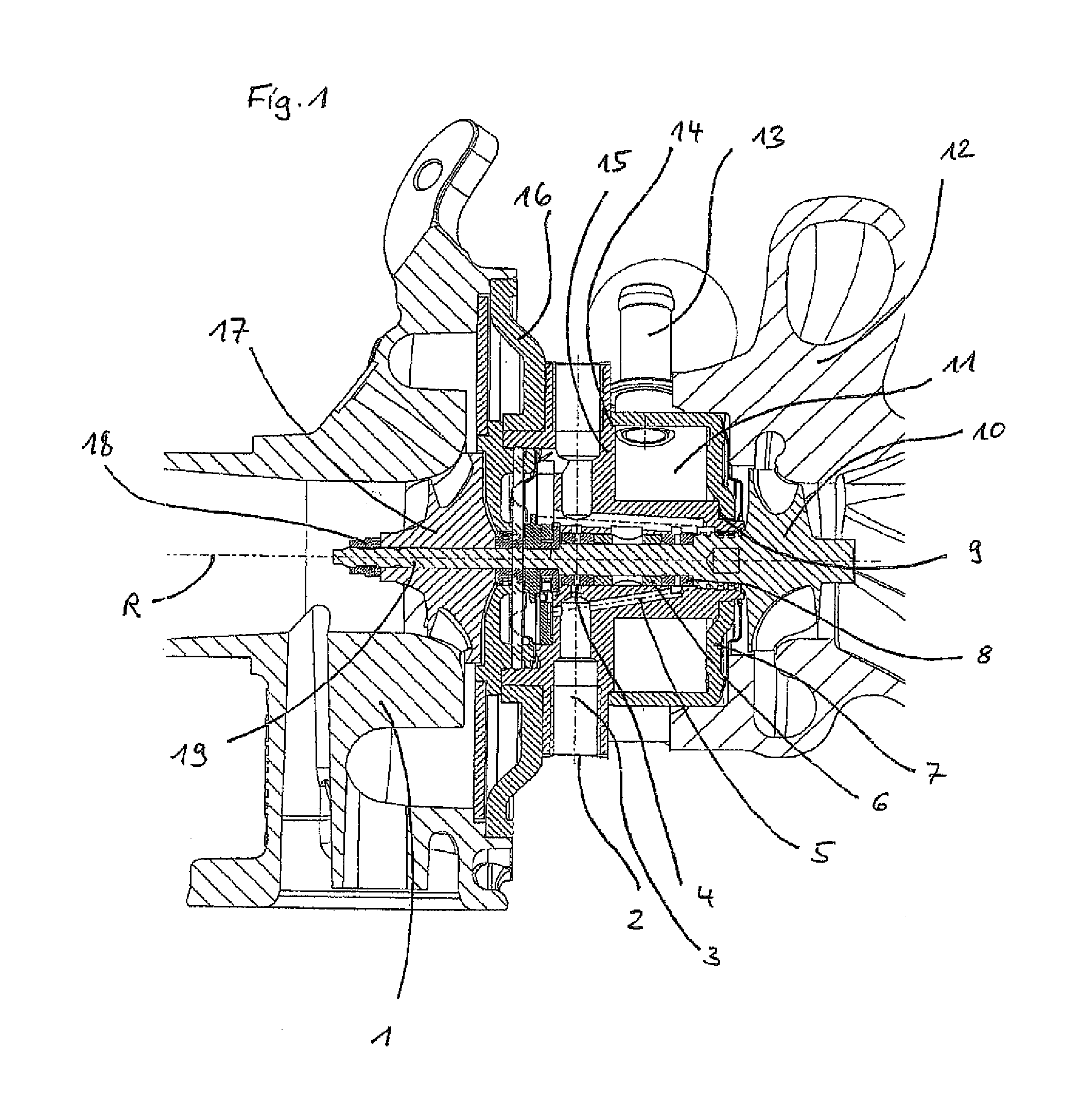

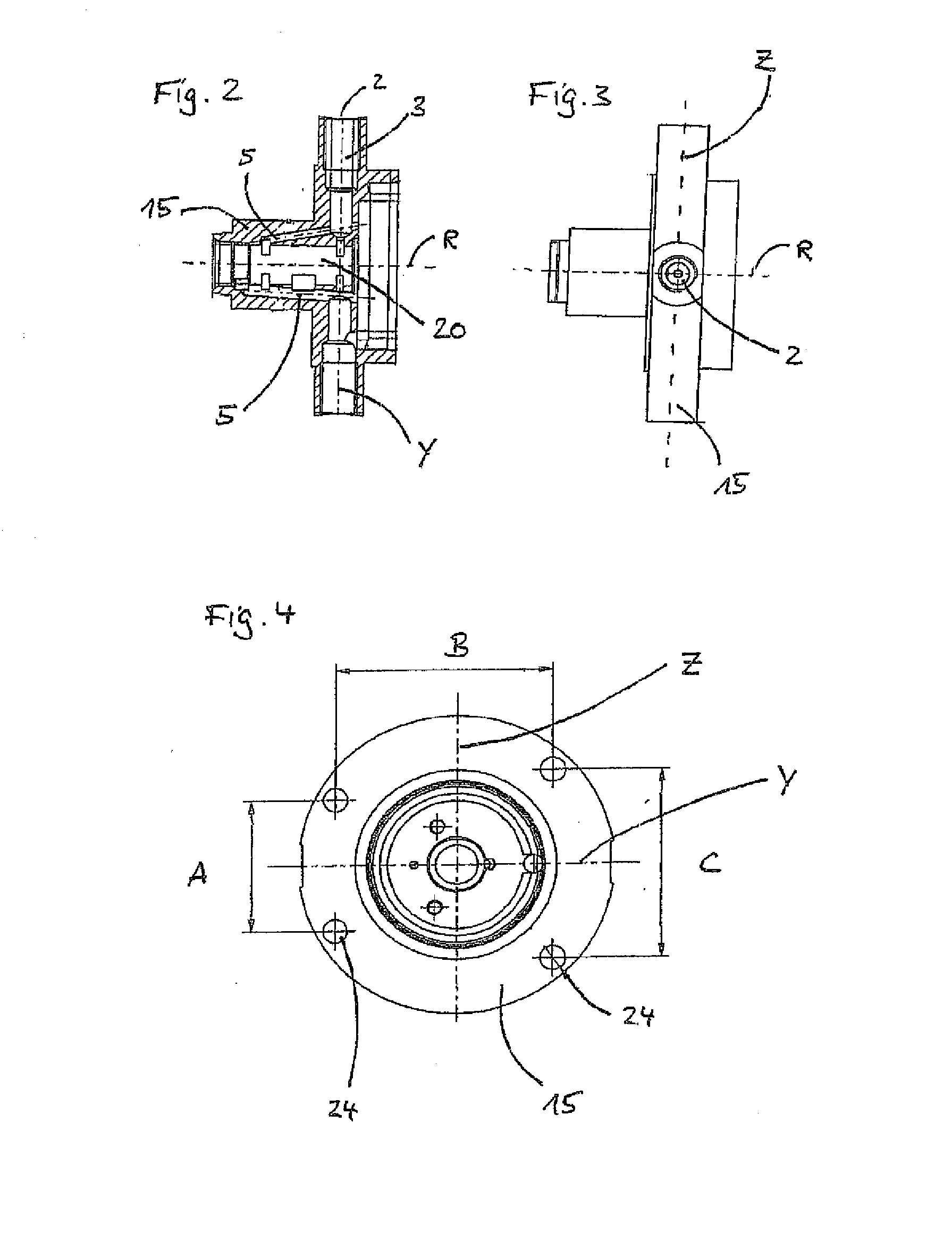

[0032]FIG. 1 shows a sliding bearing mounted turbocharger comprising a three piece turbocharger housing, in a longitudinal section along the axis of rotation R. The first housing part 15 of the turbocharger housing is configured as a machine-finished forged part, in longitudinal section along the axis of rotation R.

[0033]The turbocharger housing comprises the first housing part 15, the second housing part 7 and the third housing part 16. The turbocharger housing is arranged between the cold housing 1 and the hot housing and screwed to both of these housings.

[0034]The shaft 19 connects the turbine 10, which is arranged in the hot housing 12, to the compressor 17 which is fixed on the shaft 19 with help of a fixing element 18, e.g. a nut. The shaft 19 is configured in one piece with turbine 10 so that, due to heat conduction, a basic danger of heat migrating out of the hot housing 12 into the cold housing 1 exists.

[0035]The water conduit 11 comprises a sectional surface of a square or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com