Co-based alloy

a co-based alloy and alloy technology, applied in the field of co-based alloys, can solve the problems of inferior machinability and hot workability of ni-based alloys, harmful processing, and inferior hot workability of conventional co-based alloys, and achieve the effects of suppressing grain boundary sliding, reducing hot workability, and large

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

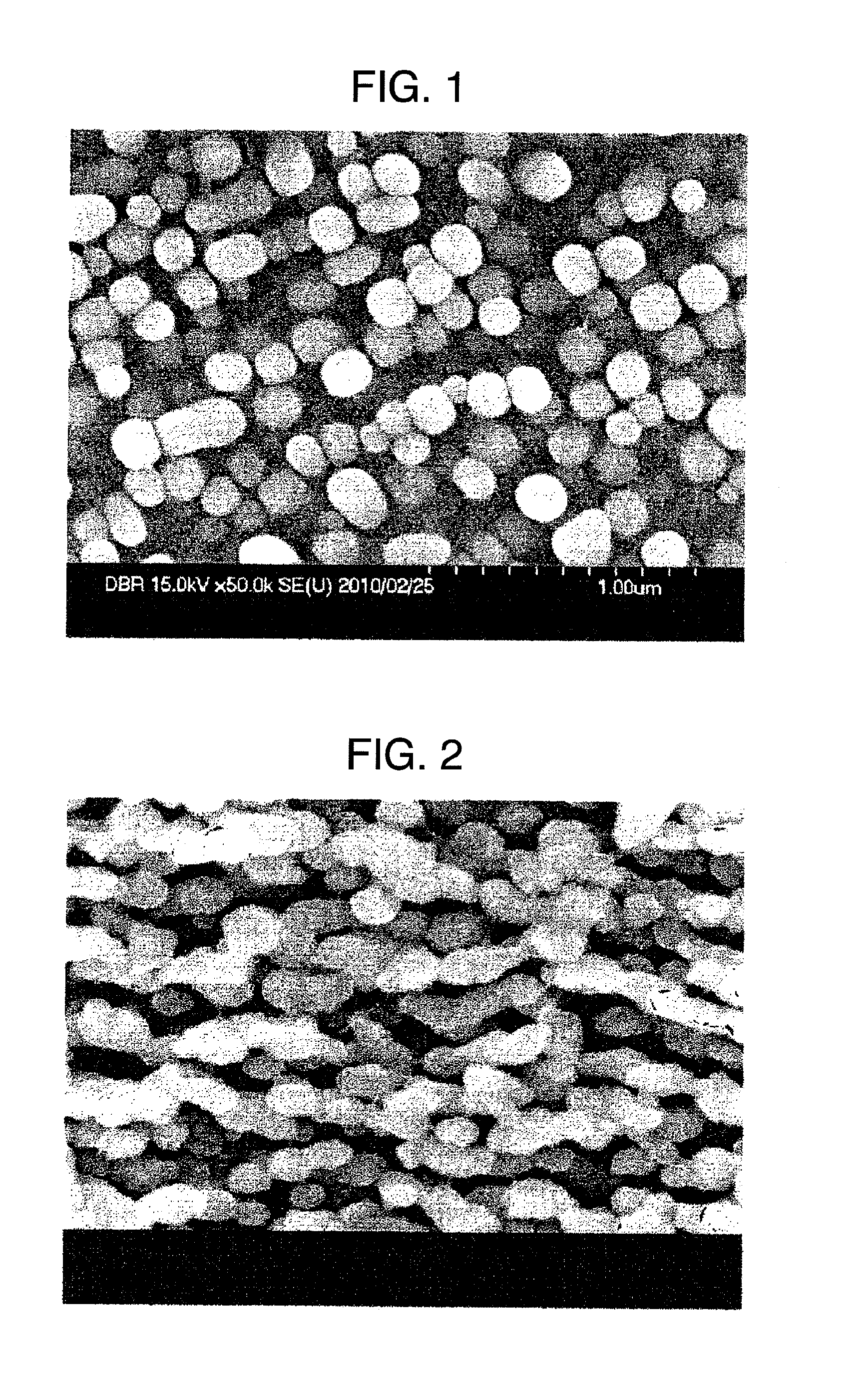

Image

Examples

examples 1 to 27

, Comparative Examples 31 to 52

1. Preparation of Specimens

[0074]Alloys having compositions shown in Tables 1 and 2 were each melted in a vacuum induction furnace to obtain a 50 kg ingot. Each ingot prepared by melting was subjected to homogenizing heat treatment at 1200° C. for 16 hours. Then, the ingot was forged into a rod having a diameter of 16 mm. Solution treatment (ST) was performed for the forged material, under conditions of 1200° C. and followed by air cooling for one hour. Then, two-step aging treatment (AG) was performed under conditions of 900° C. for 24 hours followed by air cooling, and furthermore, under conditions of 800° C. for 24 hours followed by air cooling.

TABLE 1composition (mass %)CNiCoCrWAlBMgZrCaothersExample 10.02047.6Bal12.416.23.7—————Example 20.00448.2Ba12.115.23.9—————Example 30.06046.9Bal12.315.44.1—————Example 40.02040.1Bal11.915.34.2—————Example 50.02142.3Bal12.116.33.5—————Example 60.02051.2Bal12.116.03.4—————Example 70.01652.5Bal12.316.13.6—————Ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com