Circuit layer manufacturing method and portable computer thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

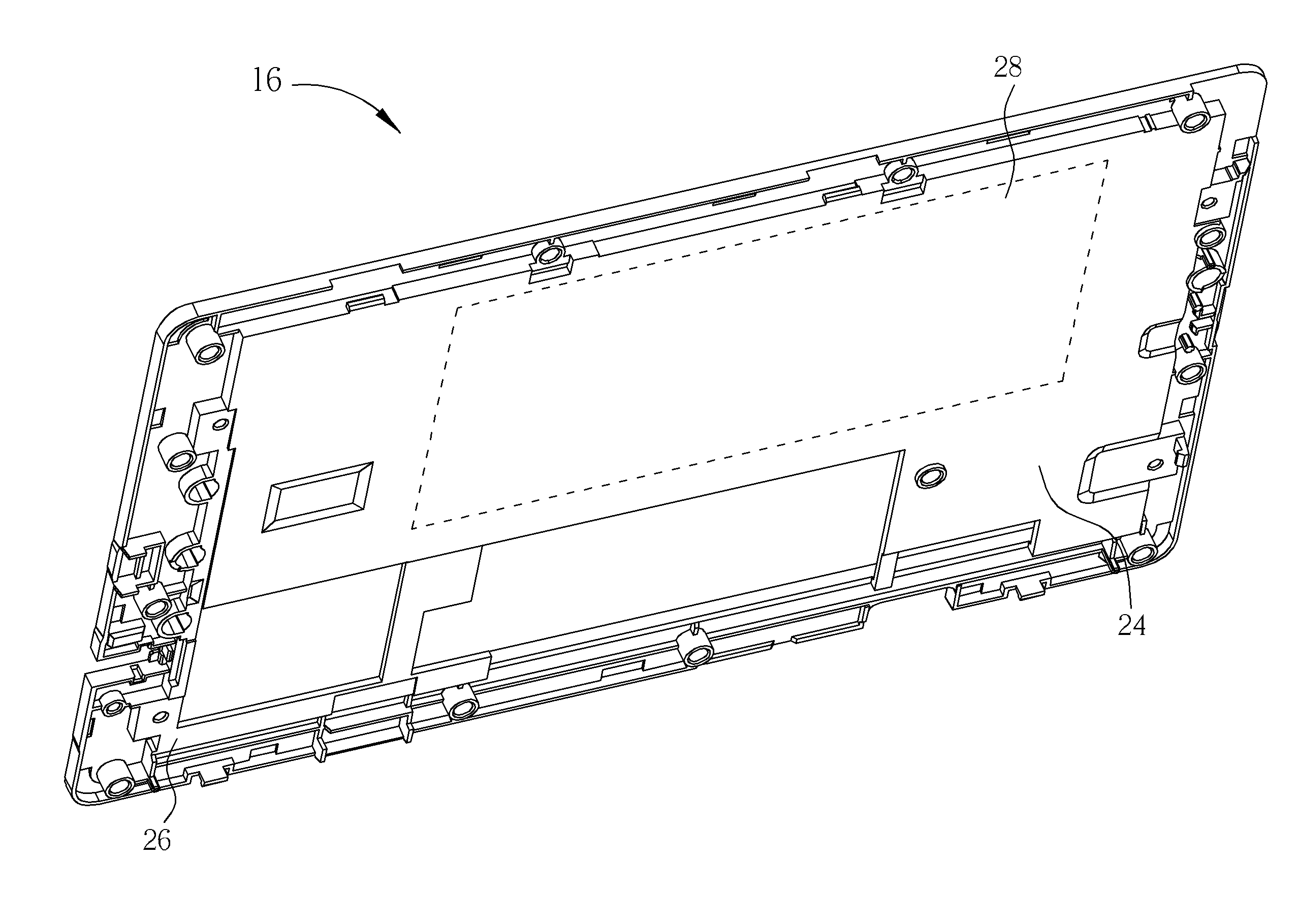

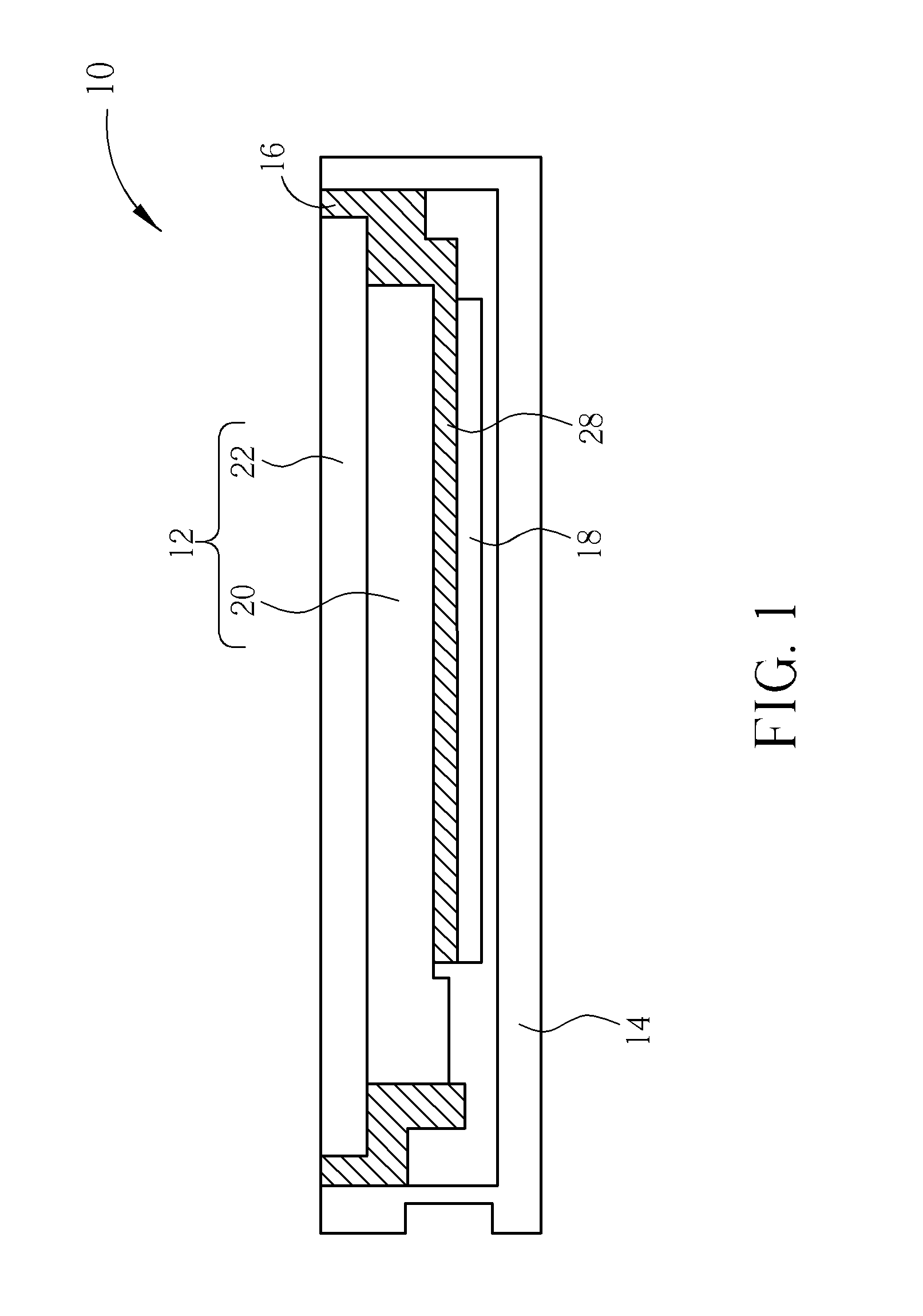

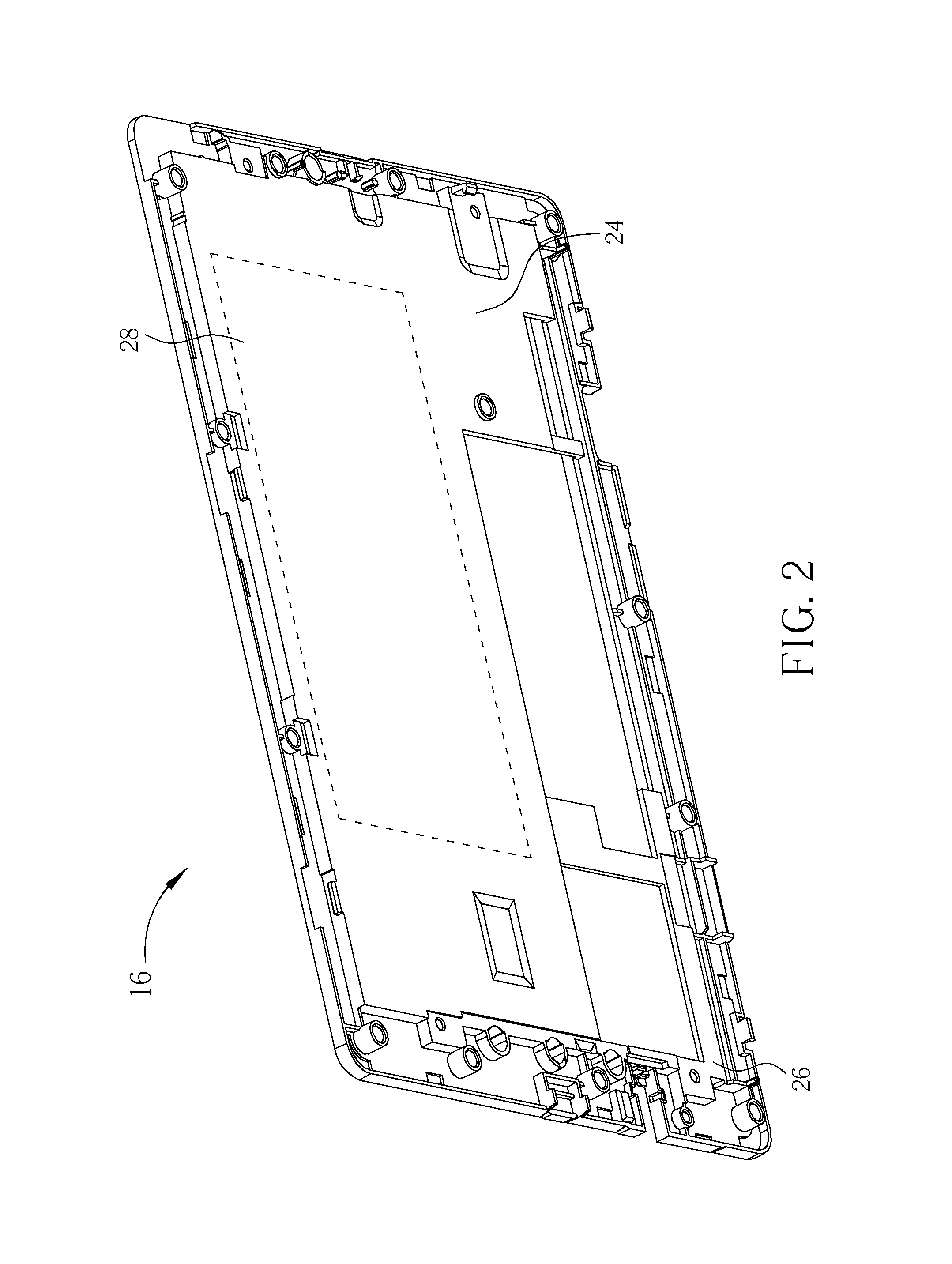

[0026]Please refer to FIG. 1, which is an inner front view of a portable computer 10 according to an embodiment of the present invention. As shown in FIG. 1, the portable computer 10 includes a display module 12, a back cover 14, a front bezel 16, and a circuit layer portion 18. The portable computer 10 can be a tablet computer, but not limited thereto, meaning that the portable computer 10 can also be other type of portable computer device, such as a notebook. In this embodiment, the display module 12 can include a display device 20 and a touch panel 22 (but not limited thereto). The display device 20 is disposed on the front bezel 16 for displaying images. The touch panel 22 is disposed on the display device 20 for providing a touch function. The front bezel 16 is connected to the back cover 14 for cooperatively containing the display module 12.

[0027]Next, please refer to FIG. 1 and FIG. 2. FIG. 2 is a diagram of the front bezel 16 in FIG. 1. As shown in FIG. 1 and FIG. 2, the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com