Manufacture of Split Tip Catheters

a technology of split tip and catheter, which is applied in the field of catheters, can solve the problems of reducing efficiency, reducing the duration of treatment needed for adequate dialysis, and effectively reducing dialysis efficiency through recirculation, so as to reduce the thickness of the septum, shorten the manufacturing time, and simplify the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

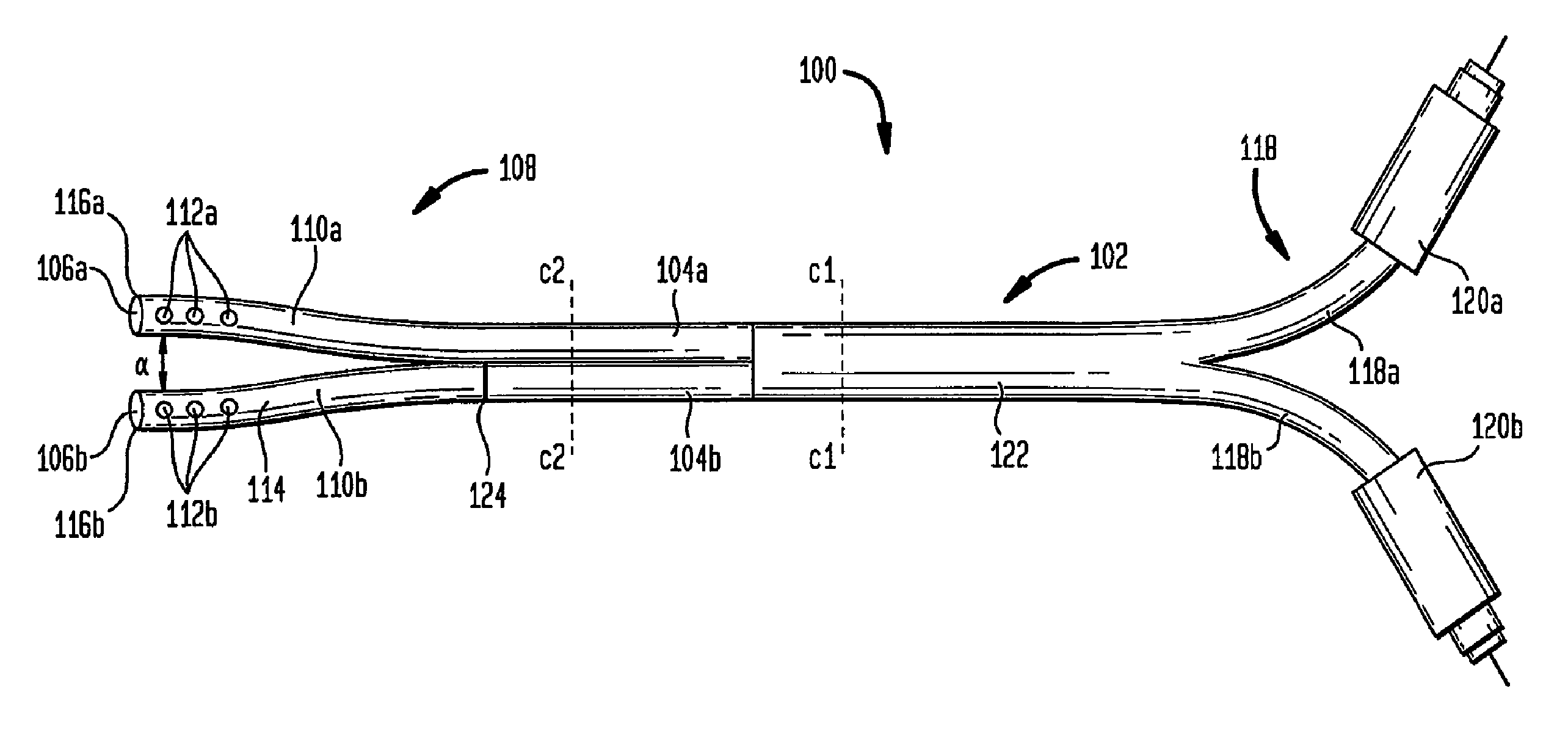

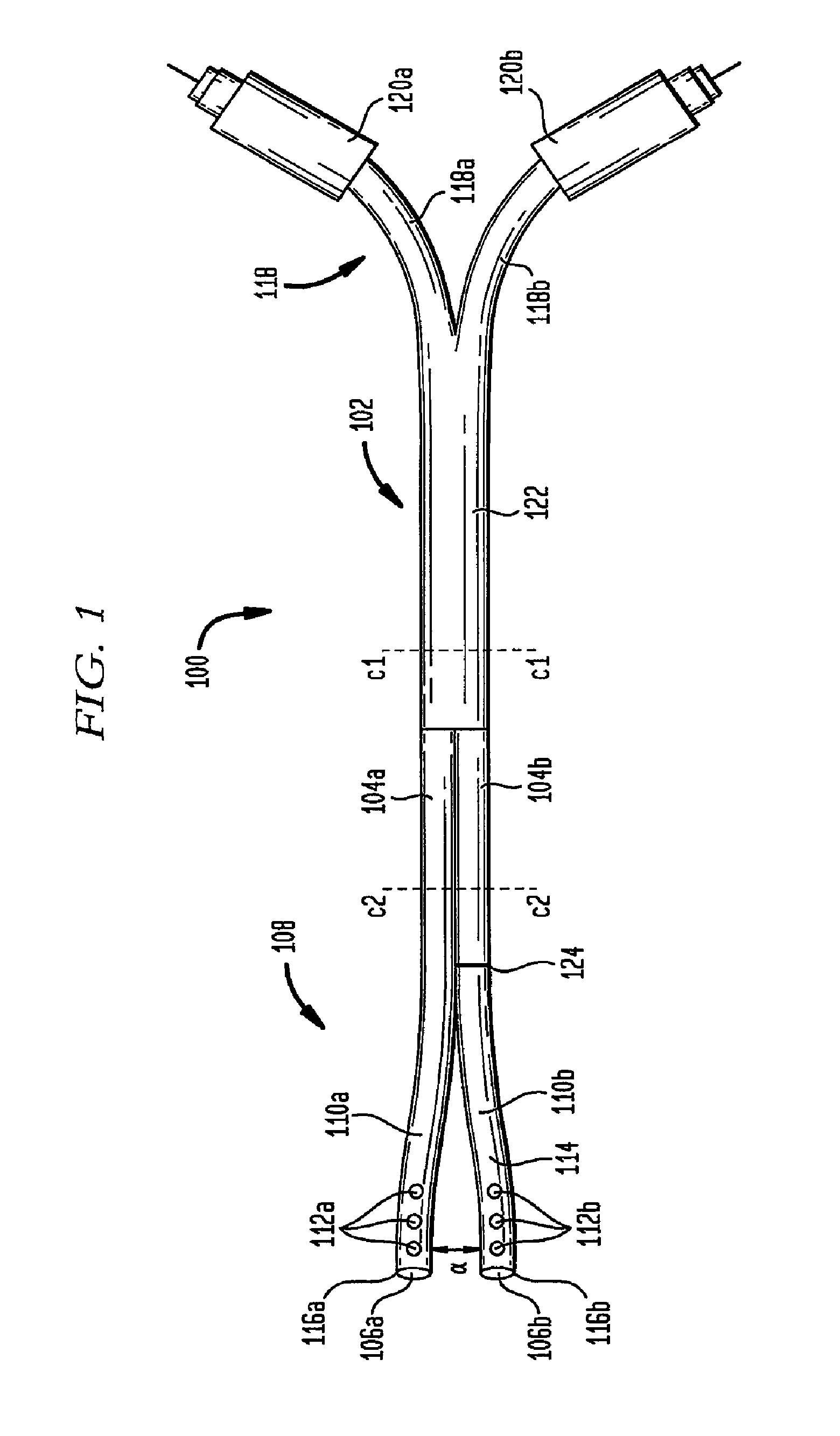

[0060]In FIG. 1 an embodiment of a split tip catheter 100 according to the invention is shown having a catheter body 102 with two internal lumens 104a, 104b (collectively, the lumens 104). The lumens 104 include respective inner lumen pathways 106a, 106b (collectively, the pathways 106) extending longitudinally through the catheter body 102. The catheter body 102 has a split-tip distal end 108 in which the catheter body 102 (and the lumens 104) separate into two distal lumen tip segments, 110a, 110b (collectively, the lumen tips 110). One of the lumens 104b has been trimmed to a length less than the other lumen 104a. A lumen tip segment 114 has been joined to the trimmed lumen 104b such that the lumen tip 110b includes the lumen tip segment 114 and such that the lumen tip segment 114 is in fluid communication with the trimmed lumen 104b. The lumen tip 110b forms an angle α with respect to the other lumen tip 110a. The value of α can be zero or non-zero and is preferably in the range...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com