Flotation for Agricultural Implements

a technology for agricultural implements and plots, applied in the field of agricultural implements, can solve the problem that it is not possible to move the implement in reverse, and achieve the effects of improving maneuverability, reducing soil disturbance, and improving performance on turns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

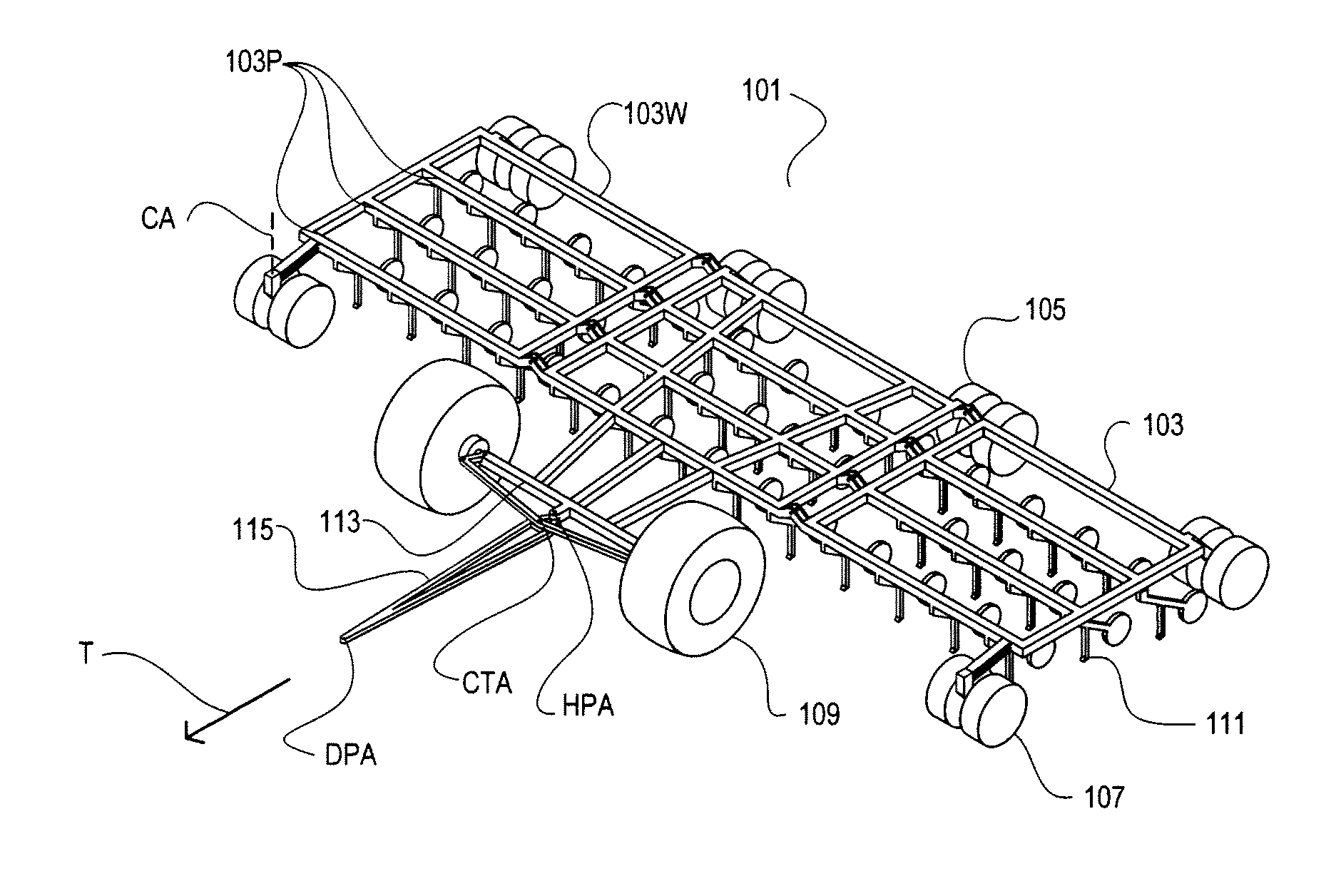

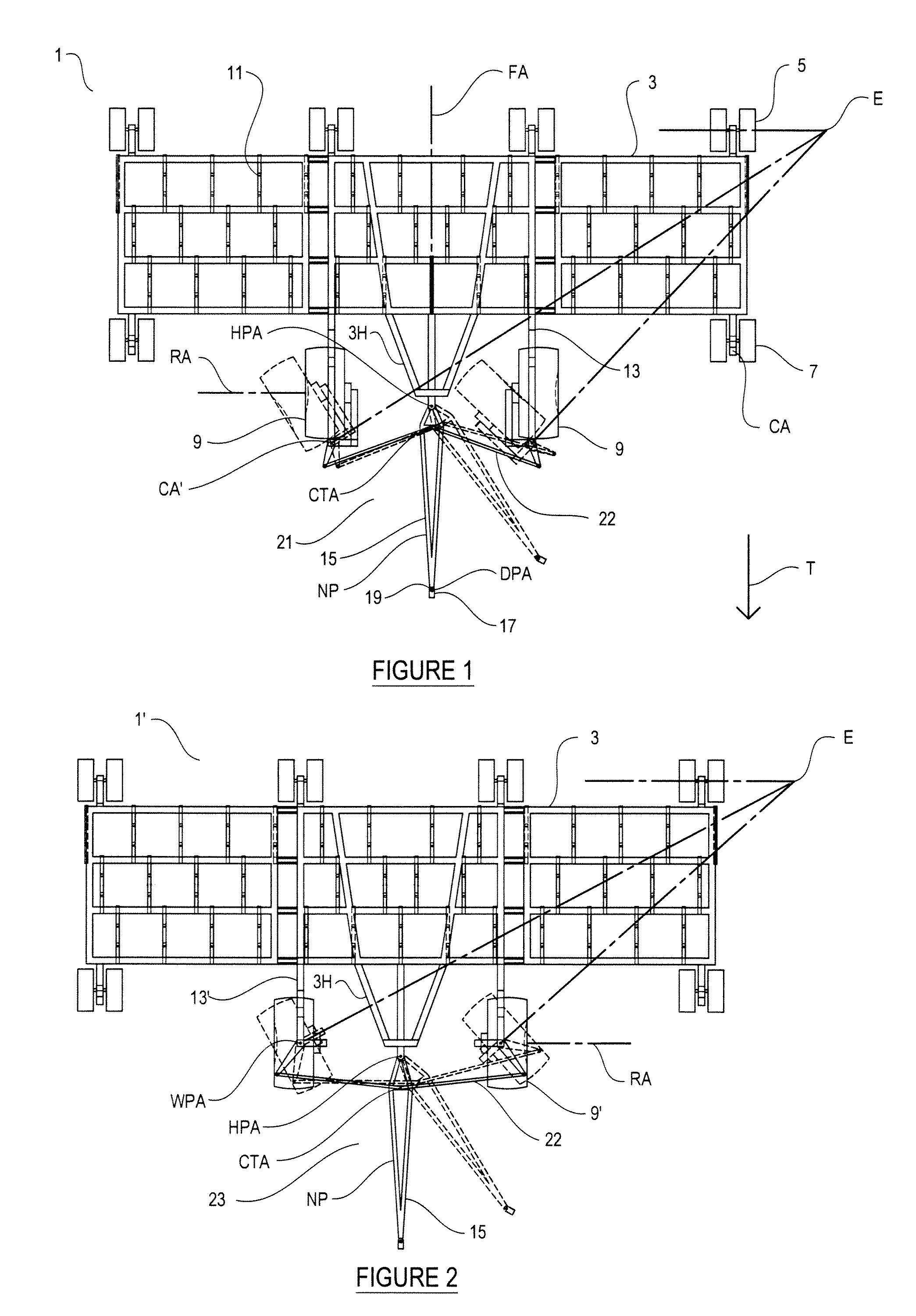

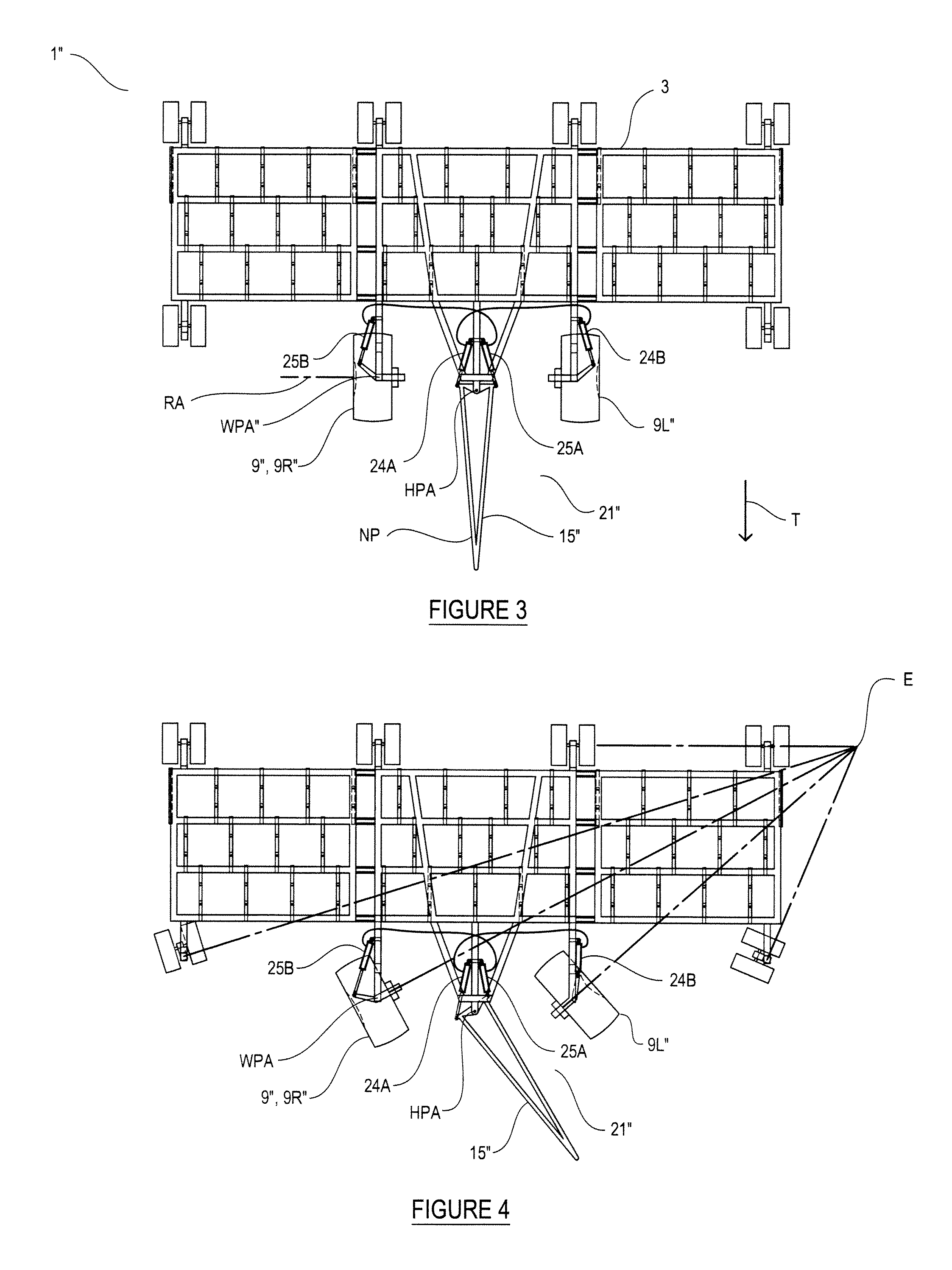

[0049]FIG. 1 schematically illustrates an embodiment of an agricultural implement apparatus 1. The apparatus 1 comprises a frame 3 supported for movement along the ground in an operating travel direction T on rear wheels 5, right and left outboard castering front wheels 7, and right and left controlled flotation front wheels 9. A plurality of ground engaging tools 11, for example the furrow openers of an air seeder or cultivator shanks, are mounted on the frame 3 substantially equally on each side of a frame axis FA extending parallel to the operating travel direction. The rear wheels 5 are fixed to the frame such that rotational axes thereof are perpendicular to the operating travel direction T. The right and left outboard castering front wheels 7 pivot freely about substantially vertical caster axes CA.

[0050]Front flotation wheels 9 are illustrated as the conventional castering type wheels pivotally mounted to the frame 3 on wheel arms 13 about substantially vertical wheel pivot a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com