Ternary fuel compositions containing biodiesel, plant oil and lower alcohols for feeding diesel-cycle motors

a technology of biodiesel and fuel composition, which is applied in the direction of biofuels, liquid carbonaceous fuels, petroleum industry, etc., can solve the problems of high cost, high cost, and high cost of cheaper fuels such as “in natura” vegetable oils, and achieve the effect of small start problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0050]Work 1: evaluation of performance and durability of engines fed with composition of the present invention with respect to petroleum diesel oil (B4).

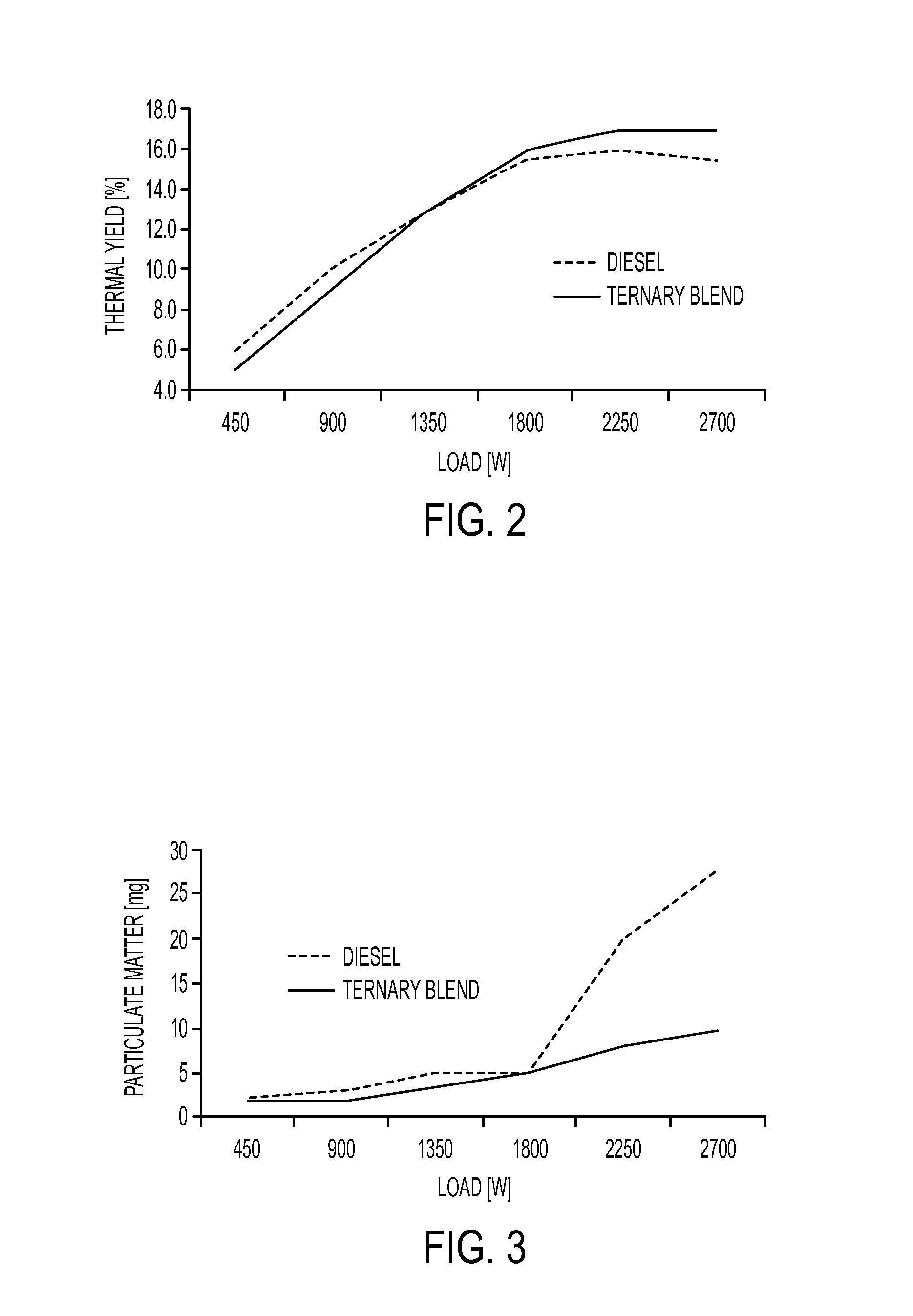

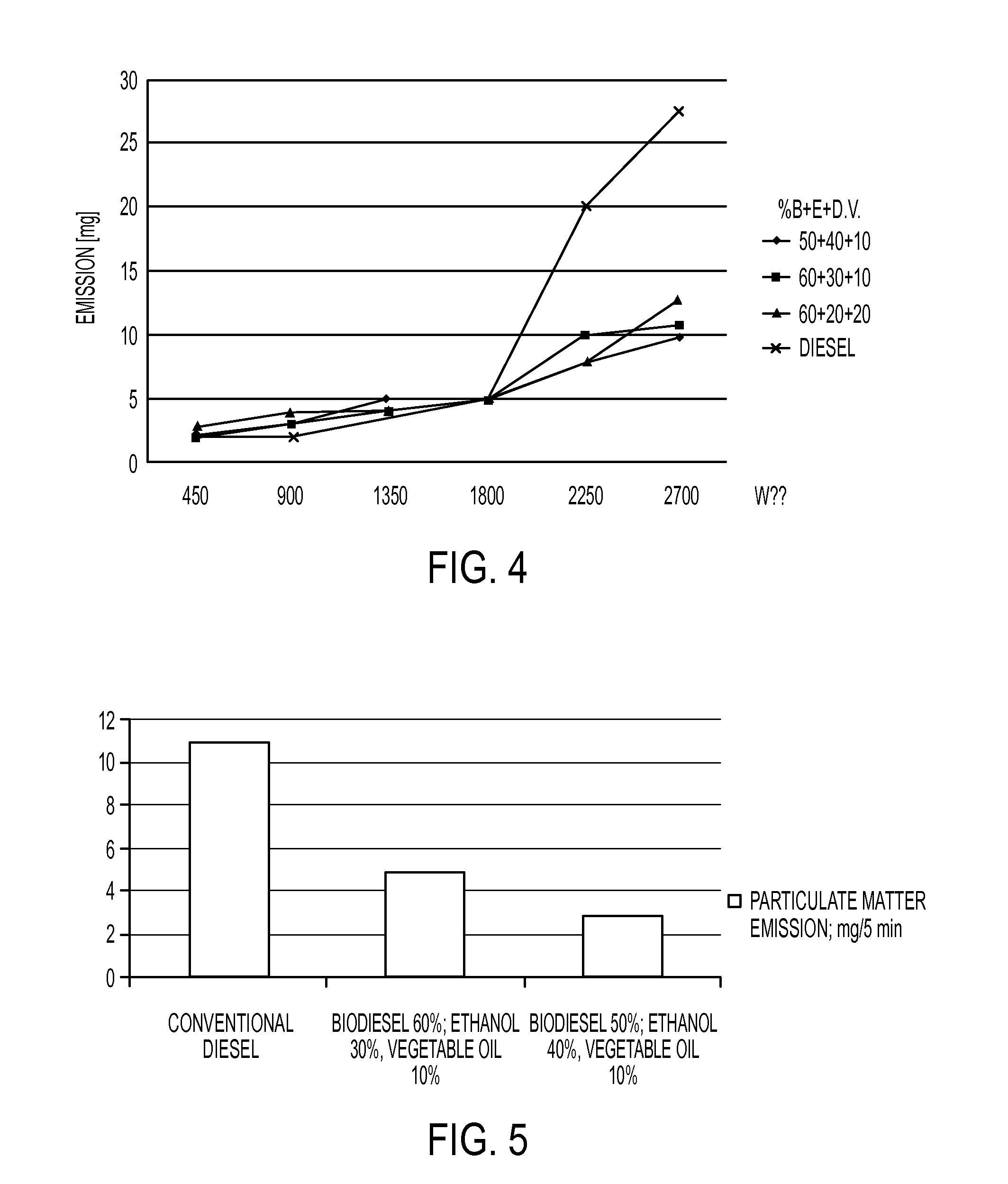

[0051]One of the experiments to evaluate the proposed technology consists of the following treatments: (i) Petroleum diesel (B4); e (ii) ternary mixture: 50% biodiesel+40% anhydrous methanol+10% vegetable oil (volumetric composition). The fuels were tested in two 6-HP Diesel cycle engines (one for testing with diesel oil; the other for the mixture), and an electric energy generator and 18 150-W lamps were used for the purpose of energy consumption elements (load). FIG. 2 discloses the profile of thermal efficiency as a function of the load applied, so that one observes that the efficiency of the ternary mixture of the present invention behaves in a superior manner as compared with the control treatment (petroleum Diesel (B4)). Moreover, it was found out that the emission of particulates was of about 70% lower with the use of the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com