Grease composition

a composition and grease technology, applied in the field of grease compositions, can solve the problems of significant frictional force between the surfaces, complex movement inside constant velocity joints, wear on the contact surface, etc., and achieve the effects of reducing molybdenum (mo) and phosphorus (p), reducing frictional properties, and reducing molybdenum (mo) and phosphorus (p)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

1. Preparation of Grease Compositions

[0088]Grease compositions containing various additives, notably graphite and molybdenum dithiocarbamate are prepared from a same base grease comprising mineral and synthetic base oils, thickened with a simple lithium soap prepared from lithine (LiOH.H2O), and 12-hydroxystearic acid. The composition of the base grease is indicated in Table 1 below. The term of “base grease” commonly designates for one skilled in the art, a grease composition only containing base oils and thickeners, but no additive.

TABLE 1composition of the base greaseCompound% by massMineral oils80.85Synthetic oils (PAO)9.00Simple lithium soap10.15

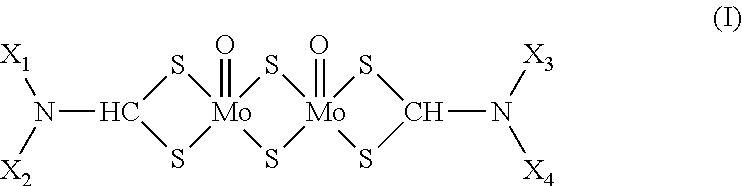

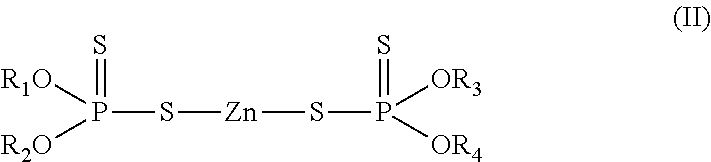

[0089]From this base grease, various additives are added: a polymer (FIB) for improving cohesiveness and adhesion, an anti-wear agent (DTPZn), and various solid lubricants: MoS2, graphite, MoDTC.[0090]The graphite used is a micrometric powder of diameter D50=6 μm[0091]The MoDTC used is molybdenum di-n-butyldithiocarbamate, containing 28...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter D50 | aaaaa | aaaaa |

| diameter D50 | aaaaa | aaaaa |

| diameter D50 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com