Hot-water heater manufacturing method and hot-water heater manufactured by the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

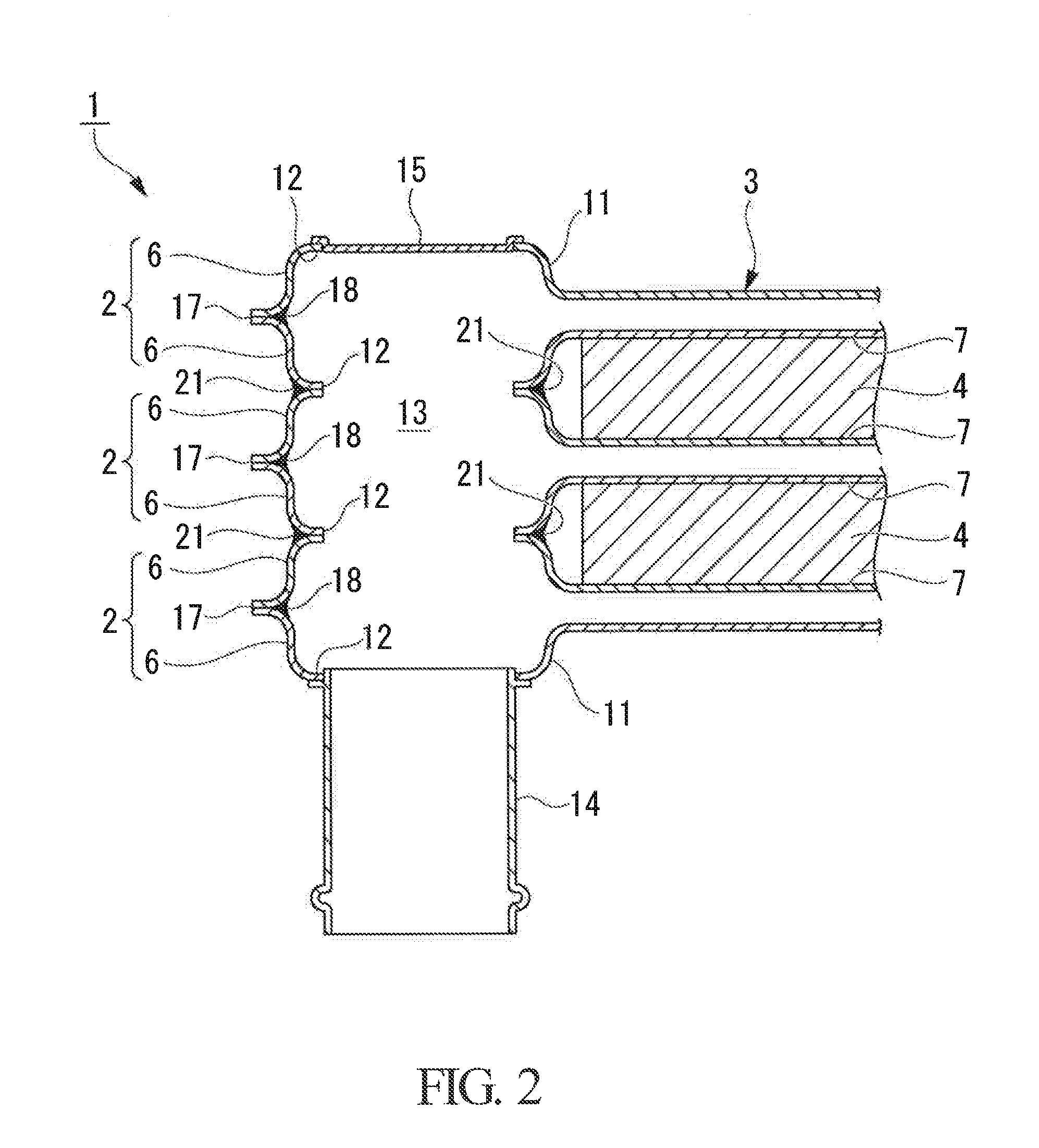

[0041]Next, a hot-water heater manufacturing method according to a first embodiment of the present invention will be described with reference to FIGS. 3 and 4. The hot-water heater manufacturing method includes a heating-medium circulating tube forming step A, a positioning and pressing step B, and a tube joining step C.

A. Heating-Medium Circulating Tube Forming Step

[0042]FIGS. 3(a) to 3(c) show the heating-medium circulating tube forming step A of forming the heating-medium circulating tubes 2. As shown in FIG. 3(a), each of the heating-medium circulating tubes 2 is composed of a pair of upper-and-lower tube constituent members 6. The tube constituent members 6 are made of a sheet-metal material, such as aluminum or brass, as described earlier, and are pressed into shapes, the tank convex portions 11 are formed in the shape of bulges at both ends thereof, and joining margins 17 are formed around the entire circumferences thereof.

[0043]The tube constituent members 6, forming a pair,...

second embodiment

[0056]Next, a hot-water heater manufacturing method according to a second embodiment of the present invention will be described with reference to FIGS. 5(a) to 5(d). The hot-water heater manufacturing method includes the heating-medium circulating tube forming step A, a positioning and pressing step B, and a tube joining step C.

A. Heating-Medium Circulating Tube Forming Step

[0057]Because the structure of the heating-medium circulating tube 2 and the heating-medium circulating tube forming step A of forming the heating-medium circulating tube 2 are the same as the heating-medium circulating tube forming step A of the first embodiment, shown in FIGS. 3(a) to 3(c), a description thereof will be omitted. However, after FIG. 3(c), a step of attaching, in advance, a brazing filler metal 24 to the circumferential portions of the heating-medium circulating holes 12 of the heating-medium circulating tubes 2, as shown in FIG. 5(a), is added. Thus, a state in which the brazing filler metal 24 ...

third embodiment

[0062]Next, a hot-water heater manufacturing method according to a third embodiment of the present invention will be described with reference to FIGS. 6(a) to 6(d). The hot-water heater manufacturing method includes the heating-medium circulating tube forming step A, a positioning and pressing step B, and a tube joining step C.

A. Heating-Medium Circulating Tube Forming Step

[0063]Because the structure of the heating-medium circulating tube 2 and the heating-medium circulating tube forming step A of forming the heating-medium circulating tube 2 are the same as the heating-medium circulating tube forming step A of the first embodiment, shown in FIGS. 3(a) to 3(c), a description thereof will be omitted. As shown in FIG. 6(a), on the circumference of one (for example, lower) side of the upper-and-lower heating-medium circulating holes 12 of each of the heating-medium circulating tubes 2 of the third embodiment, an upright fitting flange 27 (fitting part) that is formed continuously in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com