An overflow structure of a water bath vaporizer

A water-bath vaporizer and overflow technology, which is applied to pressure vessels, vessel discharge methods, and equipment discharged from pressure vessels, etc., can solve the problem of unbalanced distribution of water temperature areas in the lower part of the tank, increasing the difficulty of design and assembly, and poor maintenance. Convenience and other problems, to achieve the effect of uniform distribution of water temperature and temperature zone, convenient assembly and maintenance, and stable heat exchange process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

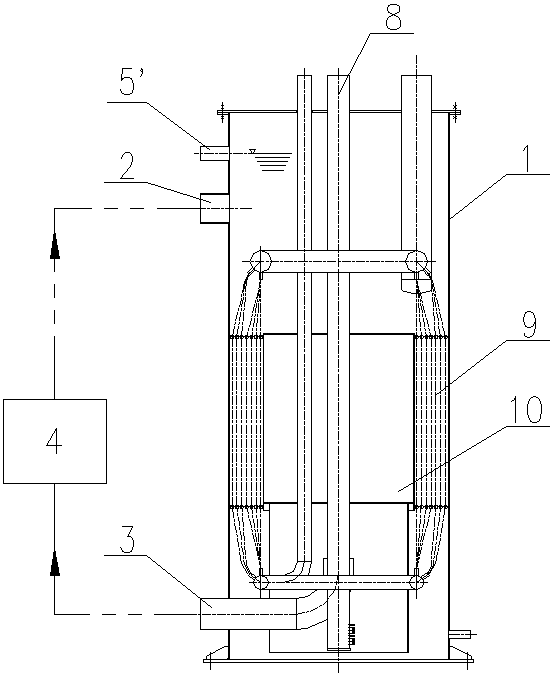

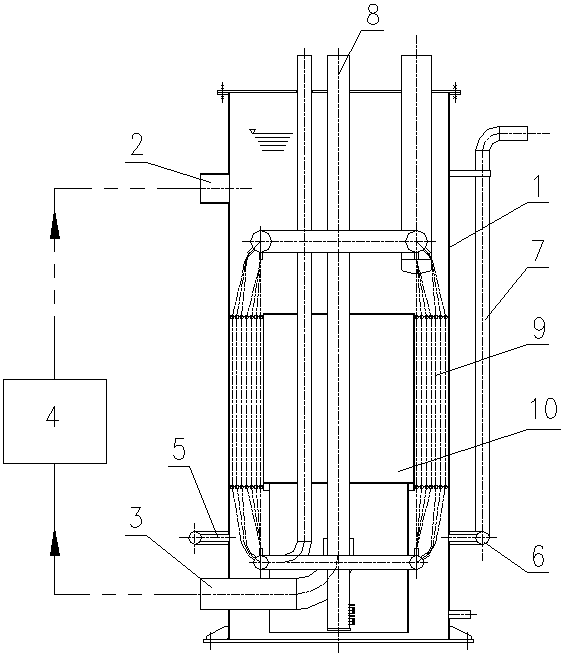

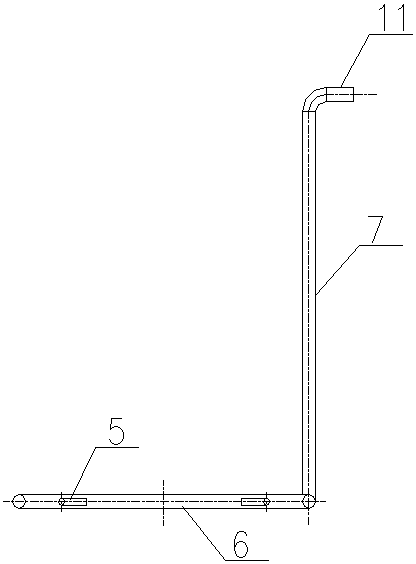

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0024] see Figure 1 ~ Figure 4 In the embodiment of the present invention, a water inlet 2 is provided on the upper part of the water storage cylinder 1, a water outlet 3 is provided on the lower part, and a circulating water pump 4 is provided between the water outlet 3 and the water inlet 2. The medium water in the lower part of the water storage cylinder 1 and inside the central tube 10 of the tube bundle is heated by the steam injection pipe 8 and then introduced into the circulating water pump 4 through the water pump 3 for pressurization, and enters the upper part of the water storage cylinder 1 through the water inlet 2 .

[0025] The water storage cylinder 1 is provided with a water storage chamber for stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com