Electronic device cooling device

A cooling device, electronic device technology, applied in the direction of electric solid devices, electrical components, semiconductor devices, etc., can solve the problems of system collapse, system reliability reduction, chip damage, etc., to achieve the effect of smooth liquid transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

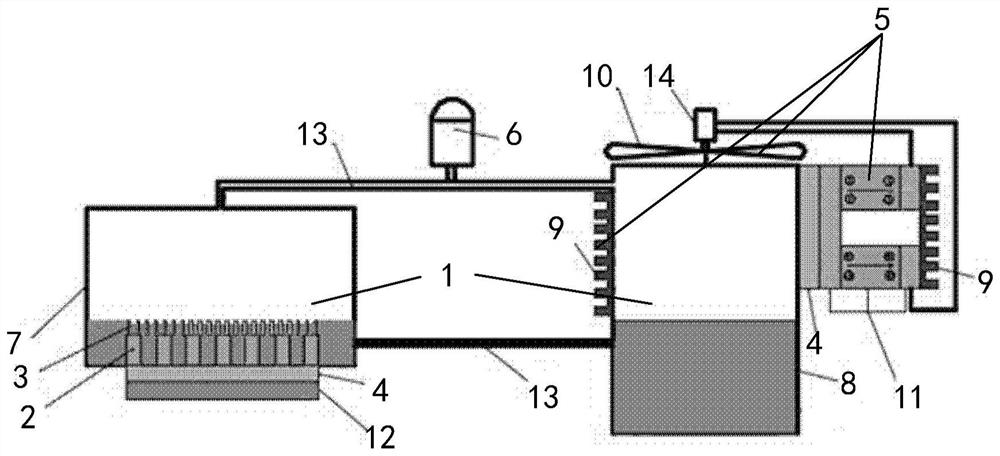

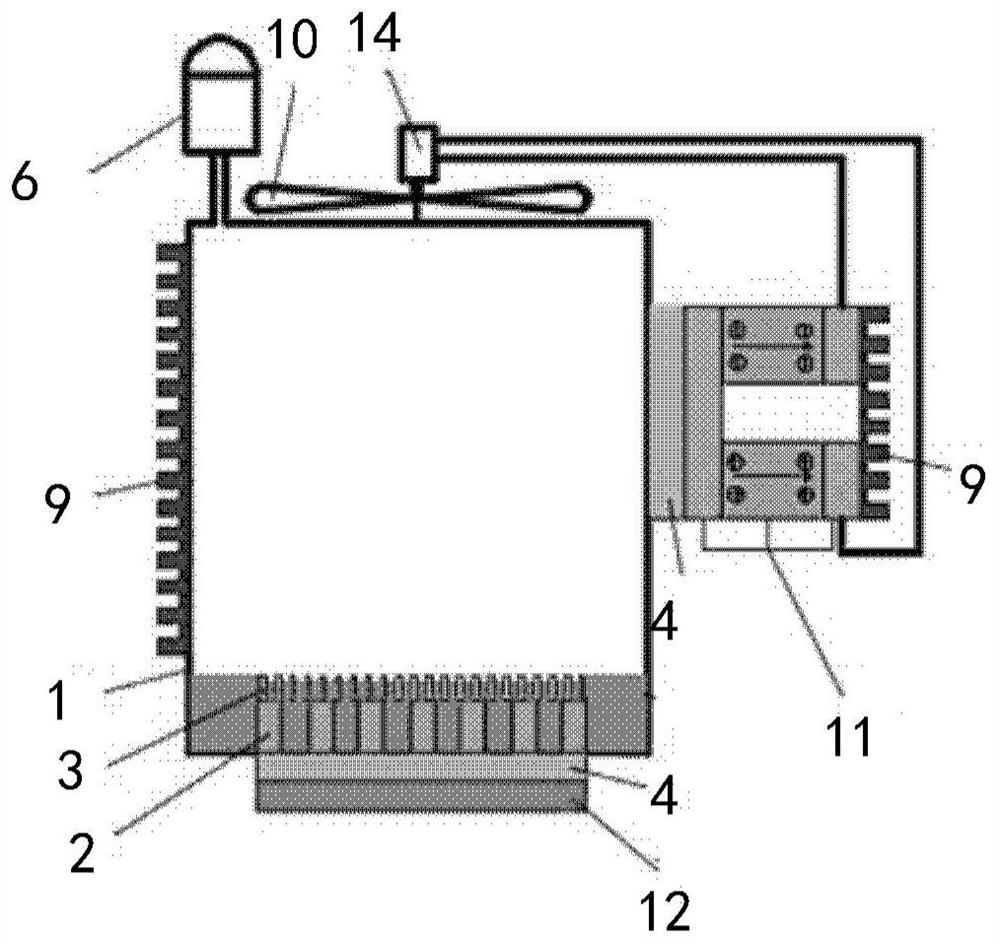

[0024] A cooling device for electronic devices, comprising a working body 1, a heat dissipation device 5 and an energy storage device 6, wherein: the working body 1, the working body 1 is a sealed cavity, a cooling medium is arranged in the sealed cavity, and a cooling medium is arranged on the inner bottom surface of the sealed cavity. A plurality of microchannels 2, the upper part of the microchannel 2 is provided with a nanoporous film 3 with capillary force, and the bottom surface of the sealed cavity is provided with a heat conduction structure 4, and the electronic device 12 exchanges heat with the cooling medium through the heat conduction structure 4; the heat dissipation device 5, It is arranged on the outer surface of the working body 1 to dissipate the heat in the working body 1; the energy storage device 6 is arranged on the upper part of the working body 1 to stabilize the pressure in the working body.

[0025] In order to make the object, technical solution and ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Inner diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com