Blade Sharpener

a blade and blade technology, applied in the field of blade sharpeners, can solve the problems of grinding dust from the blade clogging the pores of the abrasive wheel, the device has problems, and the blade is dulled, so as to prevent variations in the force of pressing the cutting edge and grind the blade further evenly and smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]Preferred embodiments of a blade sharpener according to the present invention will be described in detail below with reference to the accompanying drawings.

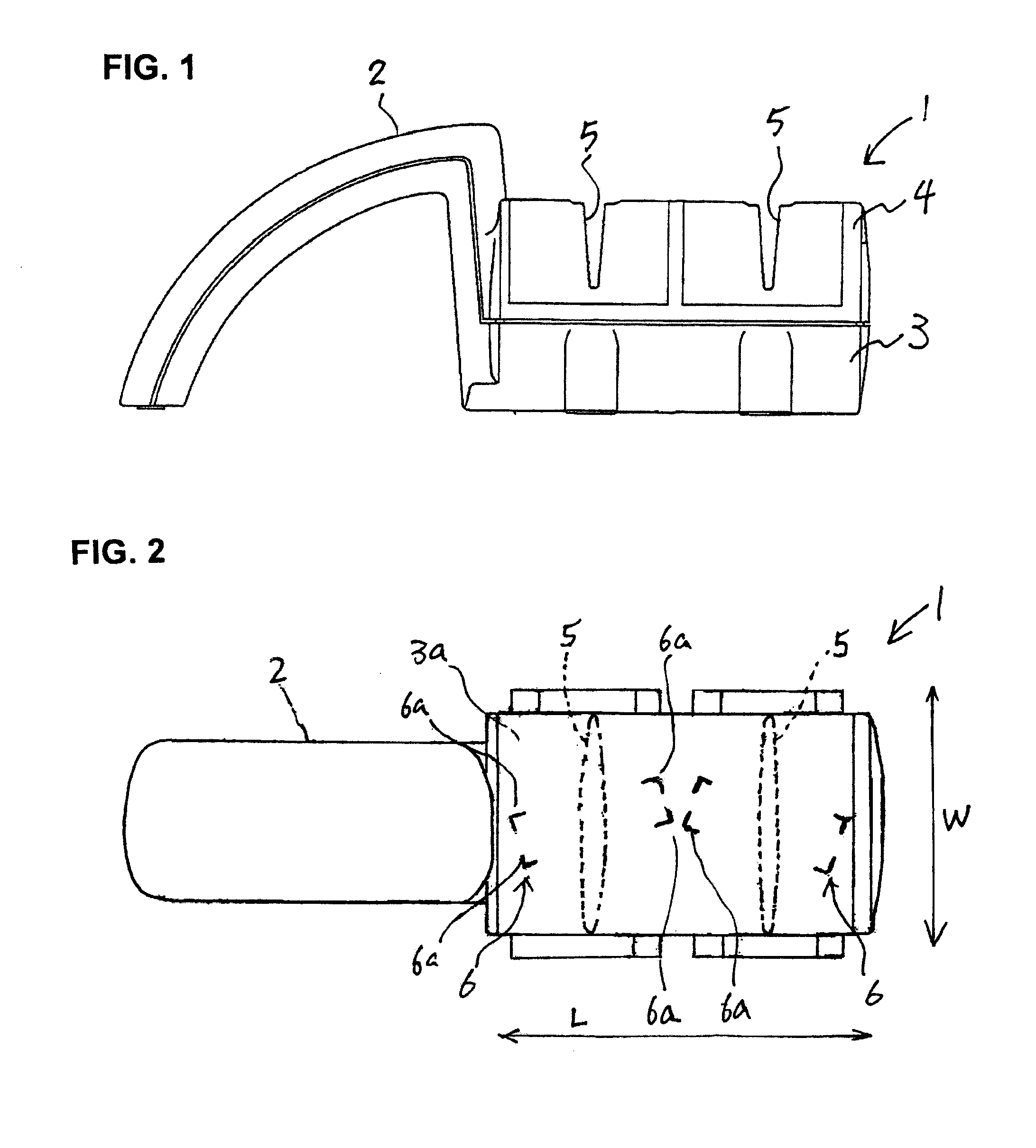

[0042]FIGS. 1 and 2 illustrate an example of a frame casing body 1 of the blade sharpener according to the present invention. The frame casing body 1 is made of, for instance, synthetic resin and includes a grip 2 and a grinding chamber 3 which is connected to the end of the grip 2 and is substantially in a rectangular box shape having a size of for instance 2.5 inches (W)×4 inches (L)×2.5 inches (H). The grinding chamber 3 is provided with a removable cover, casing 4 covering the upper opening of the grinding chamber 3, and this removable cover casing 4 is formed with two blade guide slits 5 which extend in the width direction W of the grinding chamber 3 so as to open continuously to the above and to both sides of the cover casing 4.

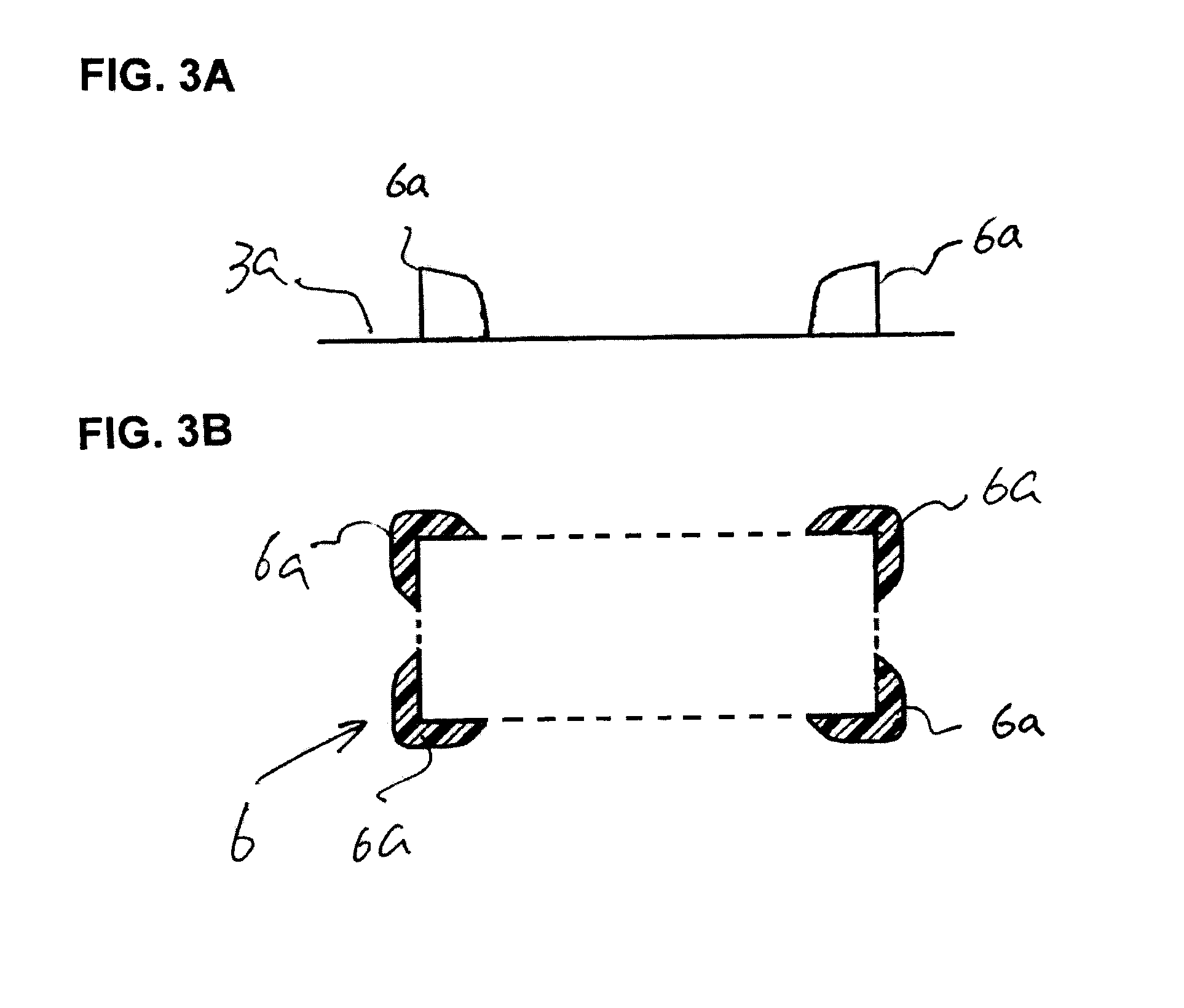

[0043]On the rectangular bottom 3a of the grinding chamber 3, one pair of (or two) holding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diagonal angle | aaaaa | aaaaa |

| diagonal angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com