Automotive friction assist system with improved traction

a technology of friction assist and automotive, which is applied in the direction of brake systems, locomotives, instruments, etc., can solve the problems of reducing traction, reducing traction, and reducing the effectiveness of antilock brakes under certain road conditions, so as to improve the traction of wheels and increase the static friction of the road surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

exemplary embodiment 10

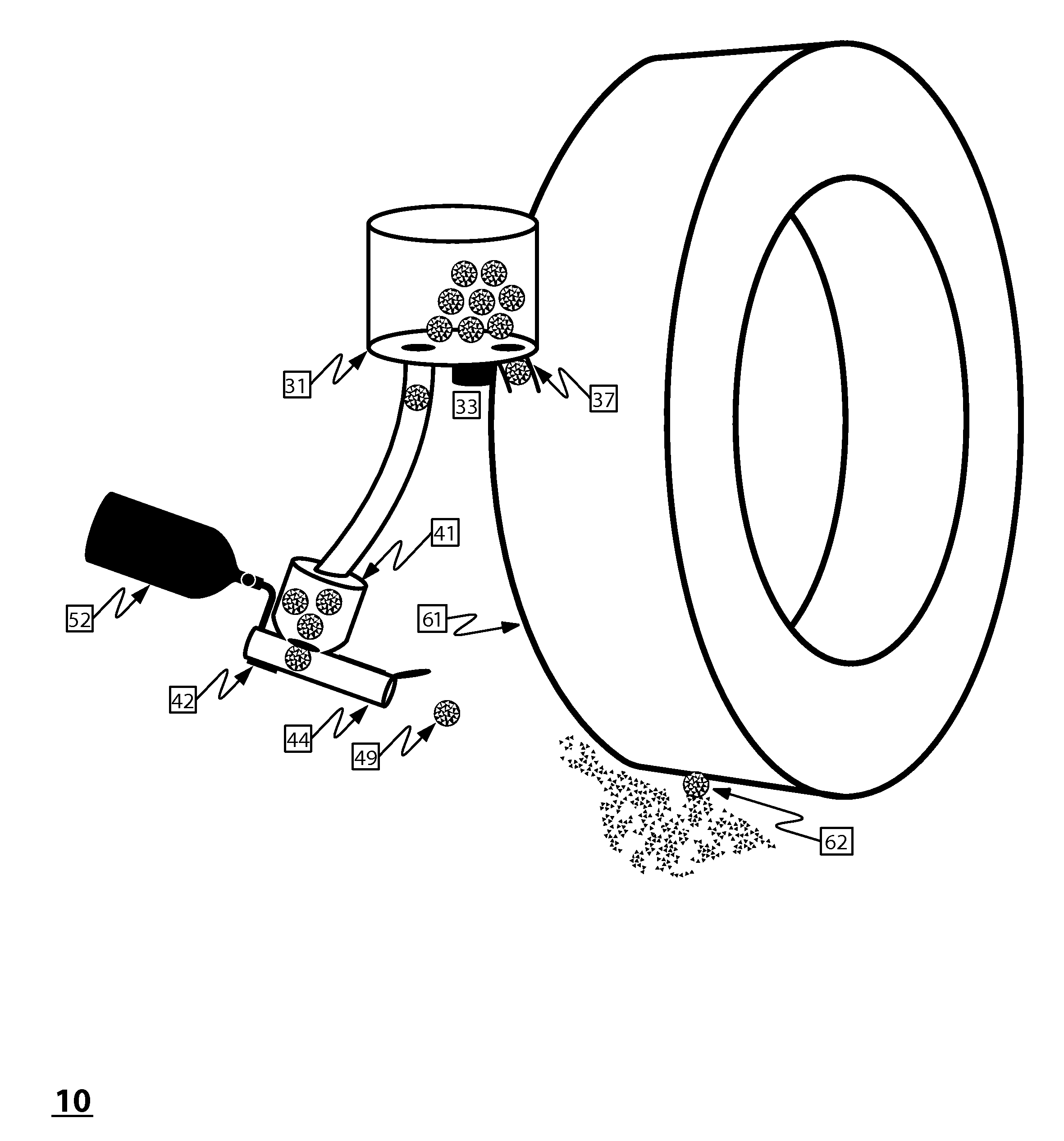

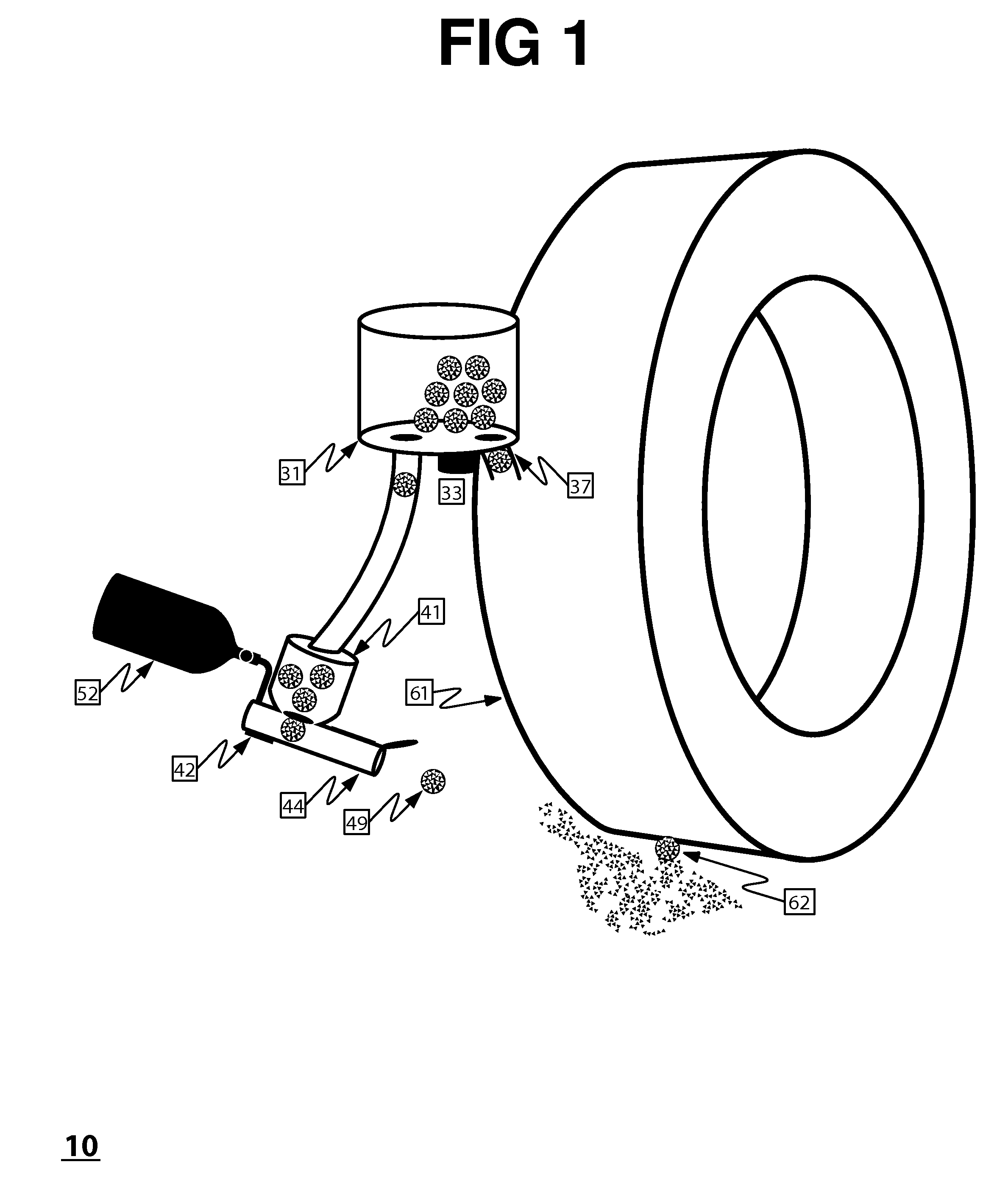

[0028]Turning to FIG. 1, shown therein is an exemplary embodiment 10 of a friction assist system of the present invention. The exemplary embodiment 10 involves sensors and computerized logic that determine when to deploy biodegradable or ceramic pellets in front of the leading edge of selected wheels of a vehicle to achieve static friction for either a desired stop condition or traction condition. Each of the elements will be discussed in detail.

[0029]Friction Pellets

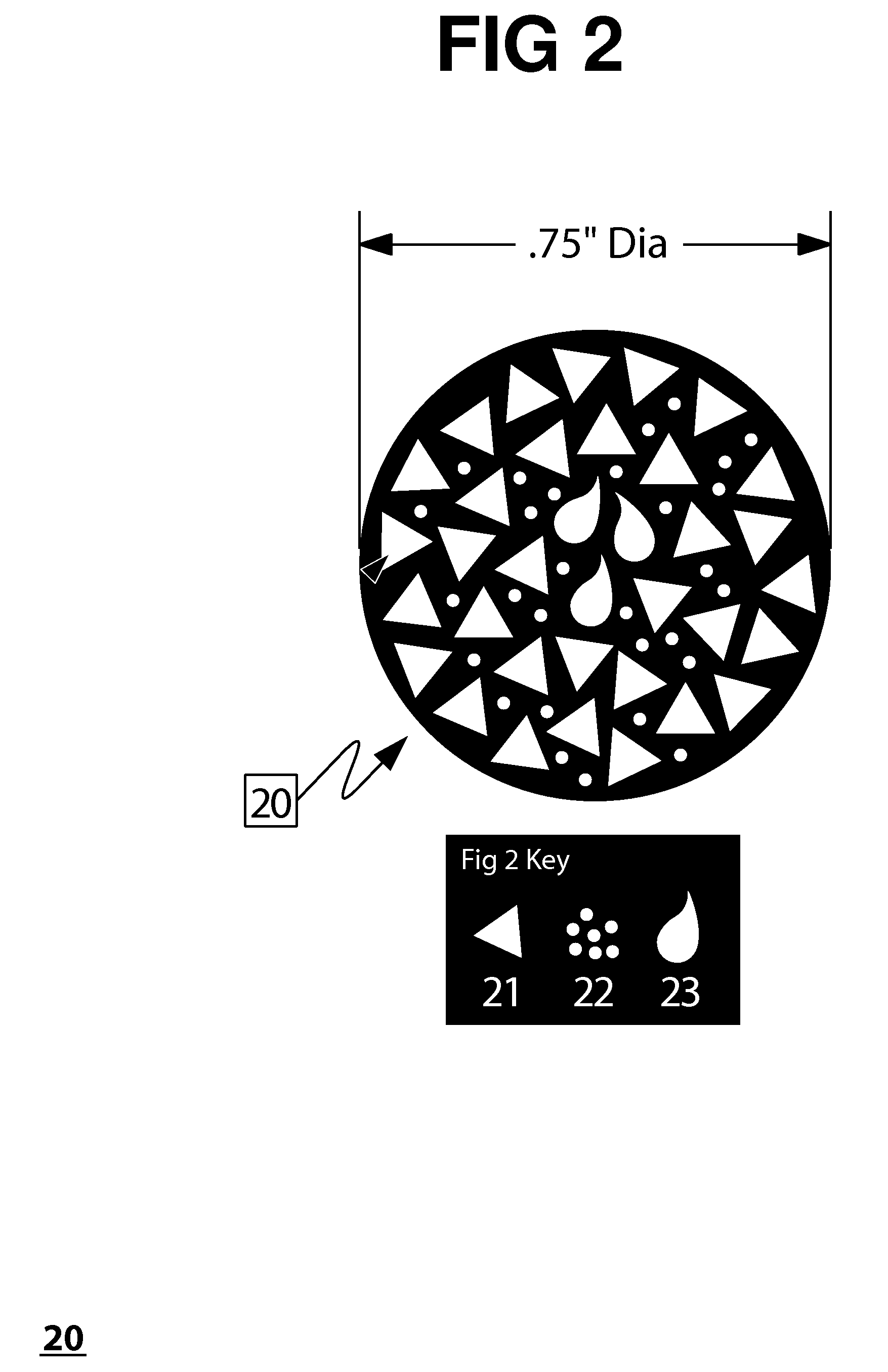

[0030]Turning to FIG. 2, shown therein is an exemplary embodiment of a pellet 20 for use in the friction assist system of the present invention. Biodegradable or ceramic pellets are used to increase the static friction of the road surface. The pellets are biodegradable so that no environmental hazard is caused by deploying them on the road surface. The diameter of the pellet 21 is selected to be about ¾ of an inch, or about 2 centimeters.

[0031]Many different pellets can be used as long as the pellets do not provide an e...

exemplary embodiment 20

[0032]Each exemplary pellet 20 contains many friction grain triangles 21 that take up most of the space inside the pellet 20. In one exemplary embodiment of the pellet, the pellet includes about 35 grain triangles, which take up about sixty percent (60%) of the interior space. Sand (or other suitable material) 22 takes up most of the remaining interior space inside pellet 20. In the exemplary embodiment of the pellet 20, sand 22 takes up about 30% of the space inside the pellet 20. The remaining space inside the pellet 20 is taken up by a colored liquid 21, such as a biodegradable soy-based colored liquid, so that one can determine if the pellet was deployed. Biodegradable materials are preferable to reduce any environmental impact by the use of the pellets of the present invention; however, other materials may still provide the necessary friction. In the exemplary embodiment 20, the colored liquid is blue soy paint 23, which takes up about 10% of the space inside the pellet 20. Suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com