Electrical water heating appliances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

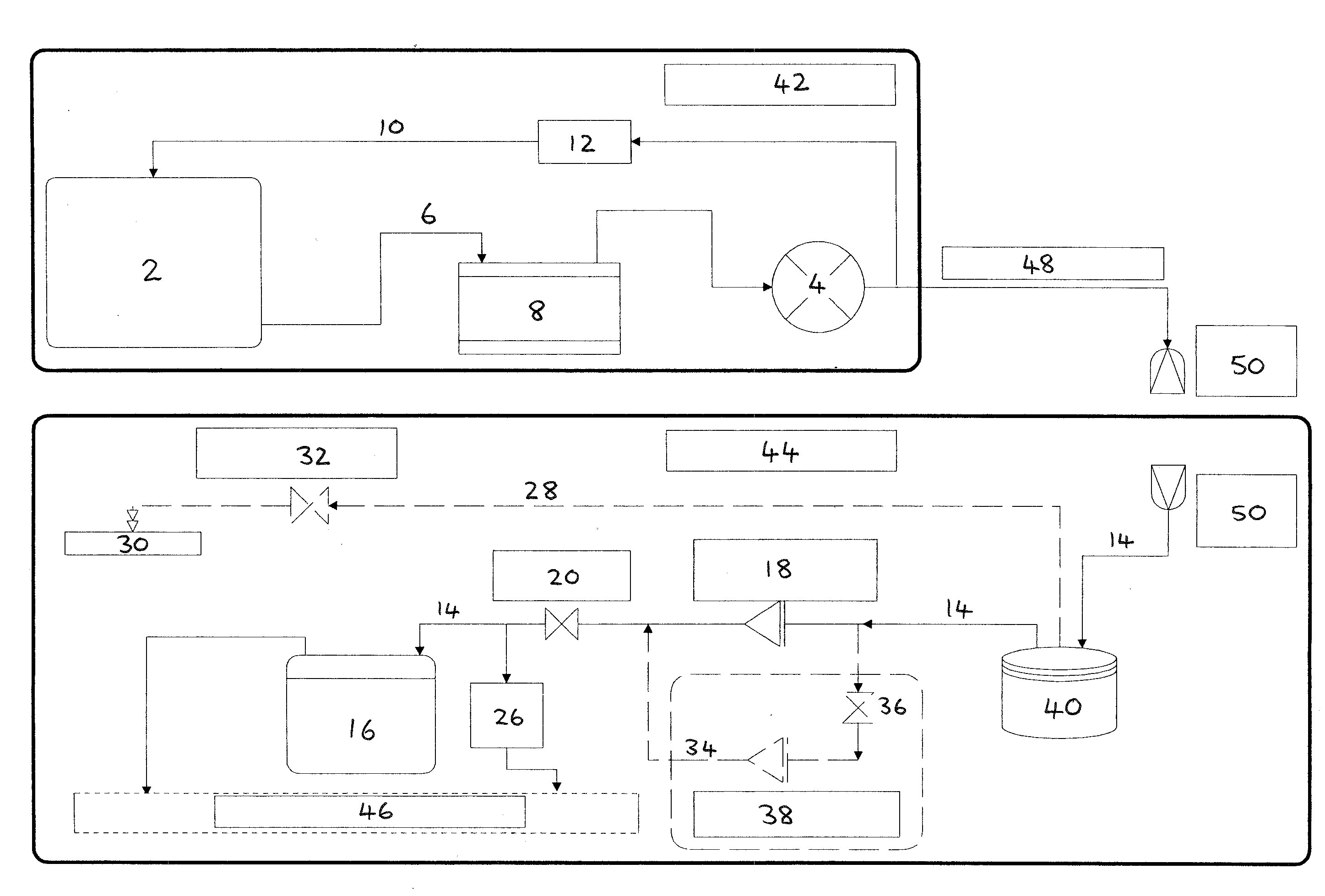

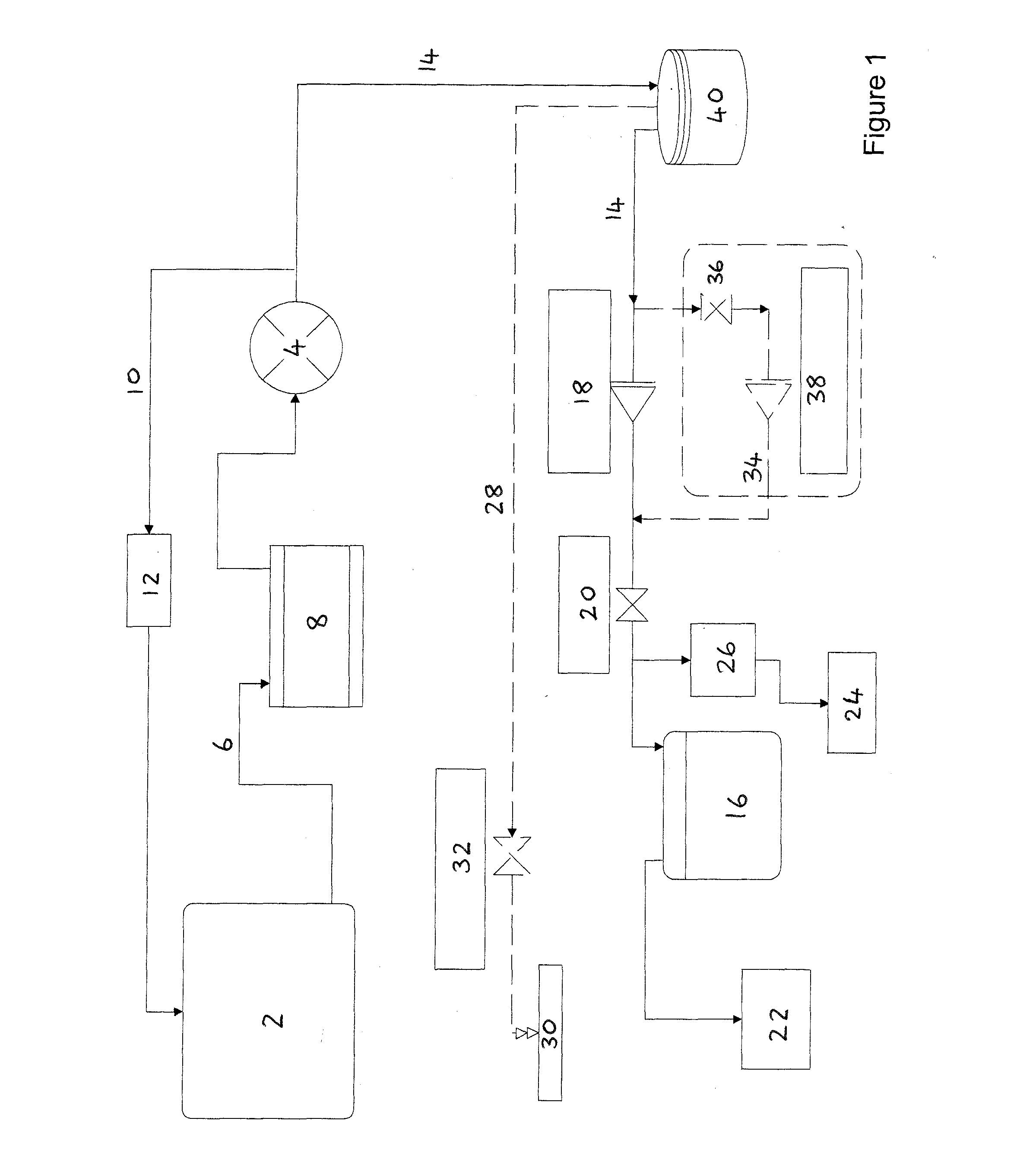

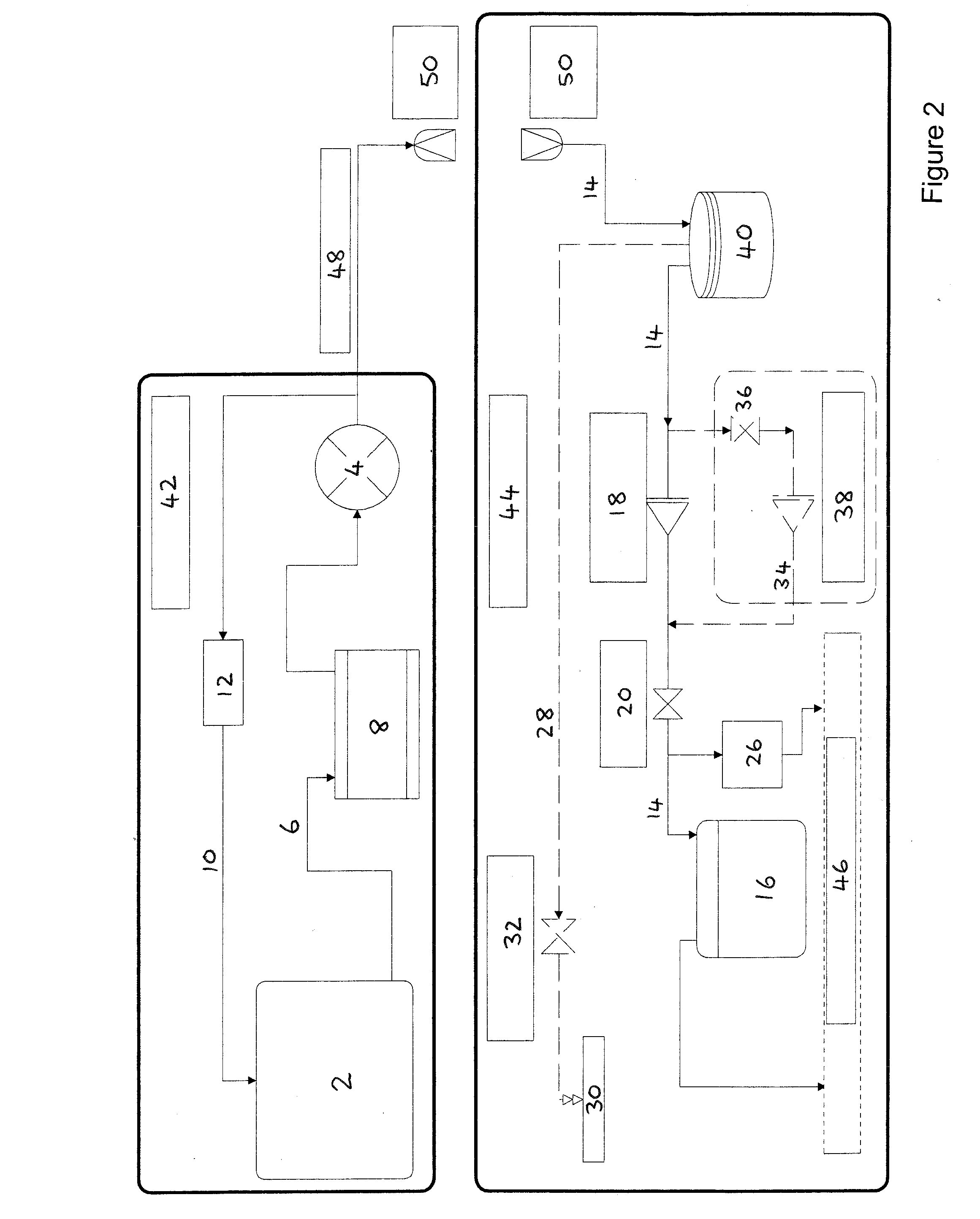

[0035]There is seen from FIG. 1 a schematic layout for the water flow path in a domestic steam generator such as a hand-held steam wand or steam iron. The appliance comprises a water tank 2 for supplying water to a pump 4. In the flow path 6 between the tank 2 and the pump 4 there may optionally be provided a water filter 8 such as an ion-exchange resin filter so that the mineral ions typically present in hard water can be removed and prevented from foiming scale deposits in the downstream components. It is also seen that a return flow path 10 may be provided from the pump 4 to the tank 2 so that the flow may be diverted back to the tank 2 by the pump 4 if necessary, for example due to a downstream blockage or failure in the system. In addition, the presence of a pressure relief valve 12 enables water to be re-circulated via the return flow path 10 so that pressurized water from the pump is fed back into the atmospheric pressure tank 2 when it is not required. This can allow the pum...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap