Bulldozer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

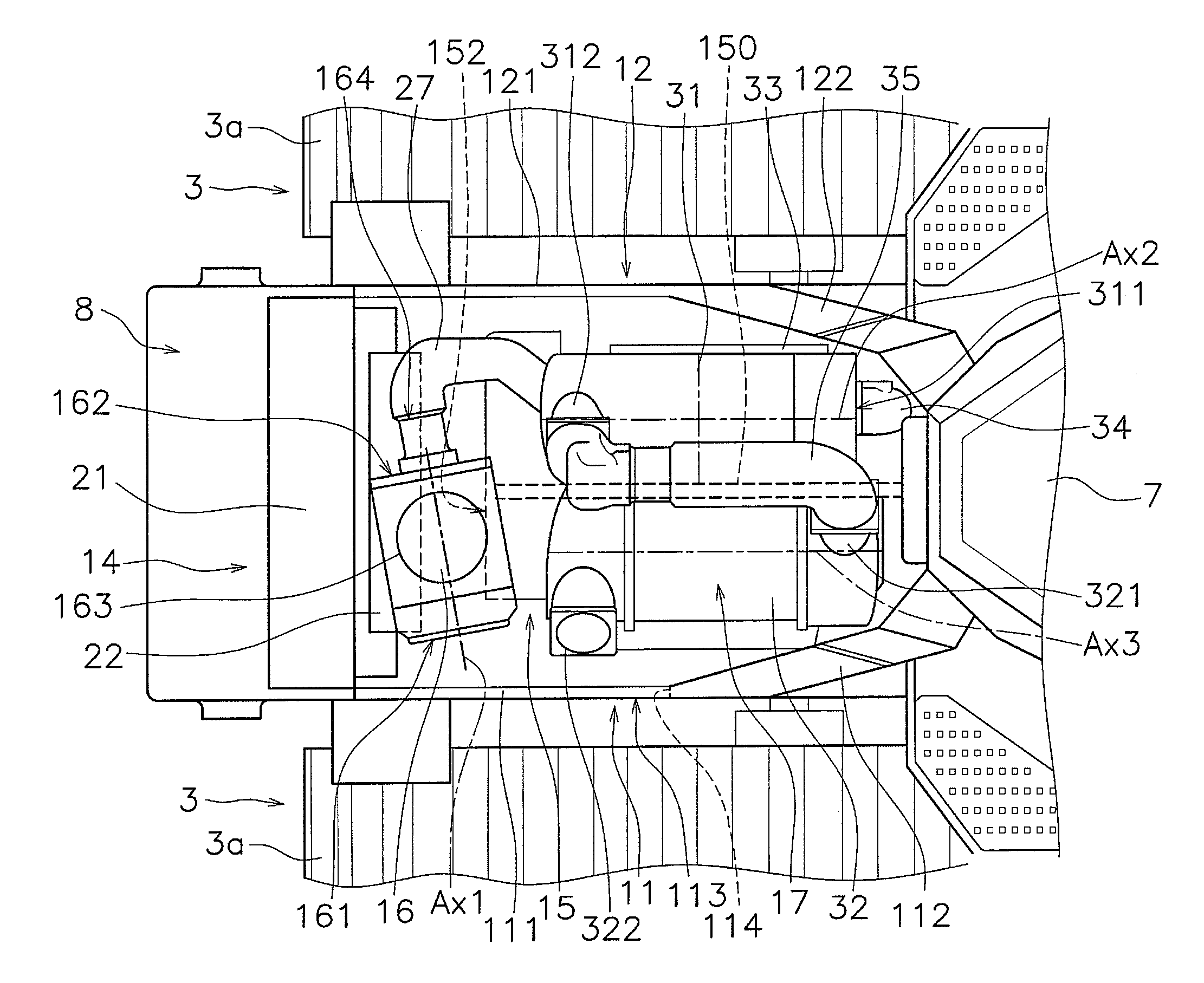

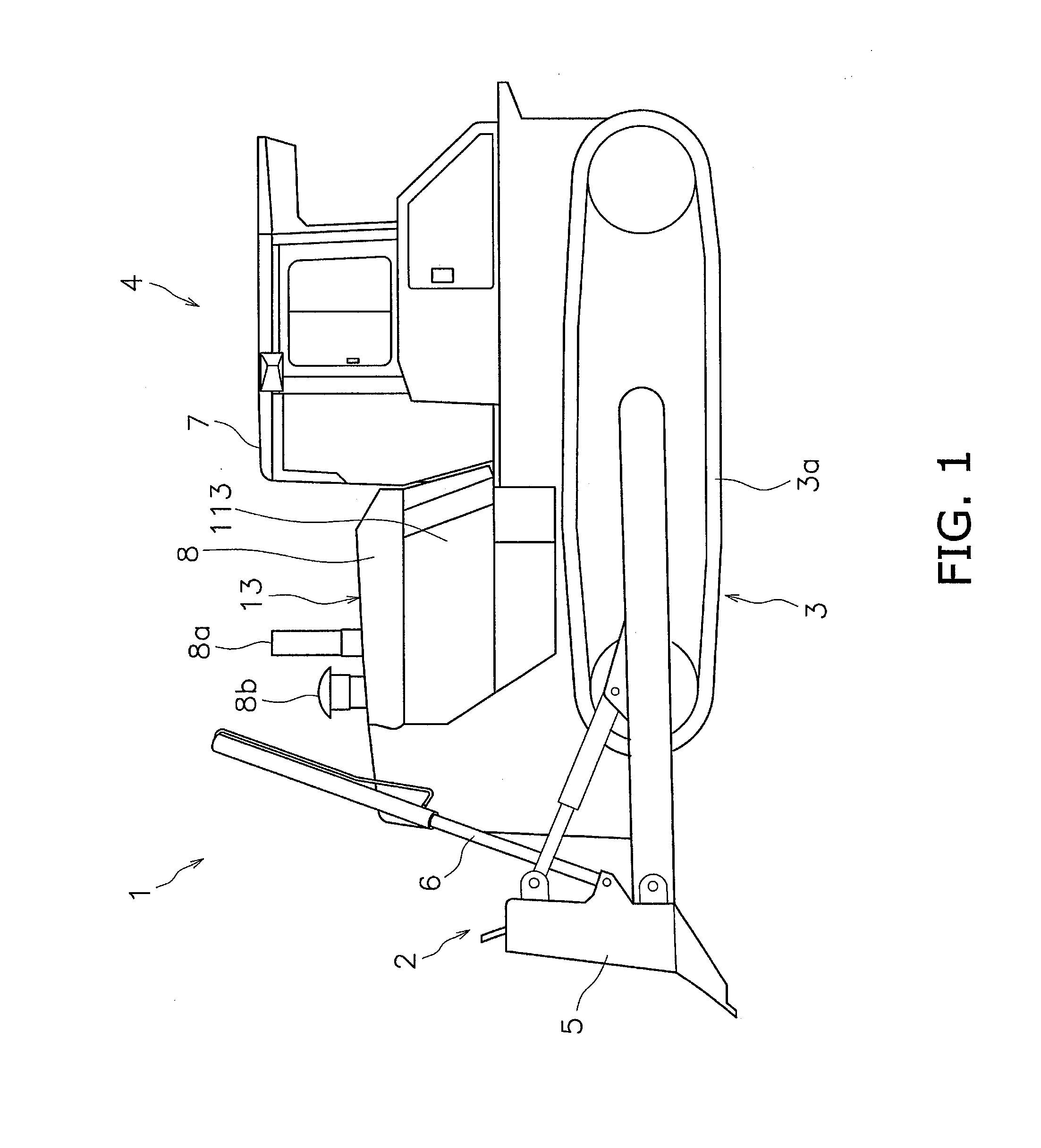

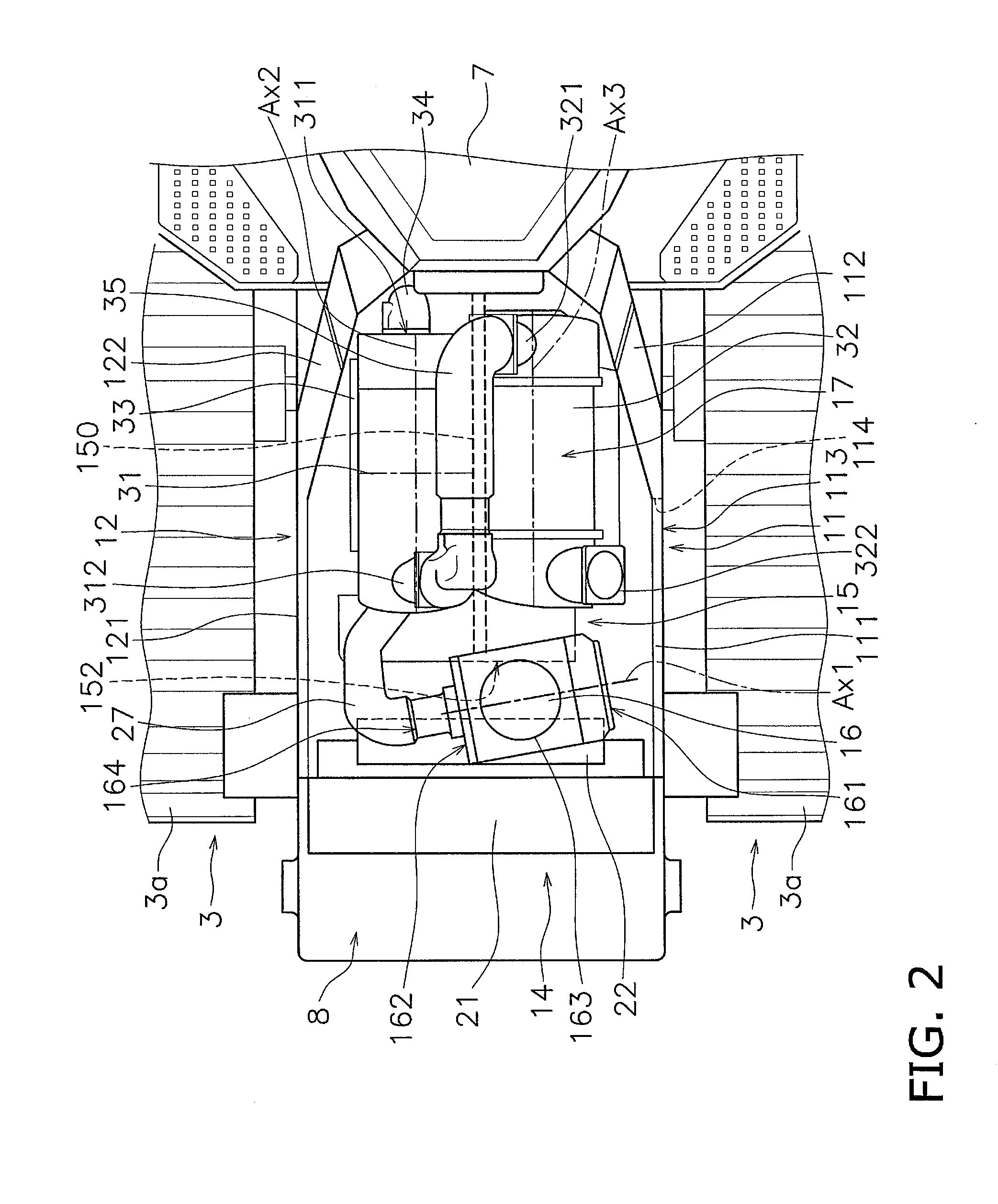

[0030]A bulldozer according to an embodiment of the present invention will now be described with reference to the drawings. FIG. 1 provides a left side view of a bulldozer according to an embodiment of the present invention. A bulldozer 1 provides a work implement 2, a traveling device 3 and a vehicle body 4. The traveling device 3 is a device that causes the vehicle to travel, and has crawler tracks 3a. As the crawler tracks 3a are driven, the bulldozer 1 travels.

[0031]The vehicle body 4 includes a cab 7 and an engine compartment 8. The engine compartment 8 is positioned forward of the cab 7. In this embodiment of the present invention forward, rear, and left and right refer to how each of these is seen from the point of view of an operator in the cab 7.

[0032]The work implement 2 is provided forward of the engine compartment 8. The work implement 2 has a blade 5 and hydraulic cylinders 6. The blade 5 is provided such that it is able to swing in the upward-downward direction. The hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com