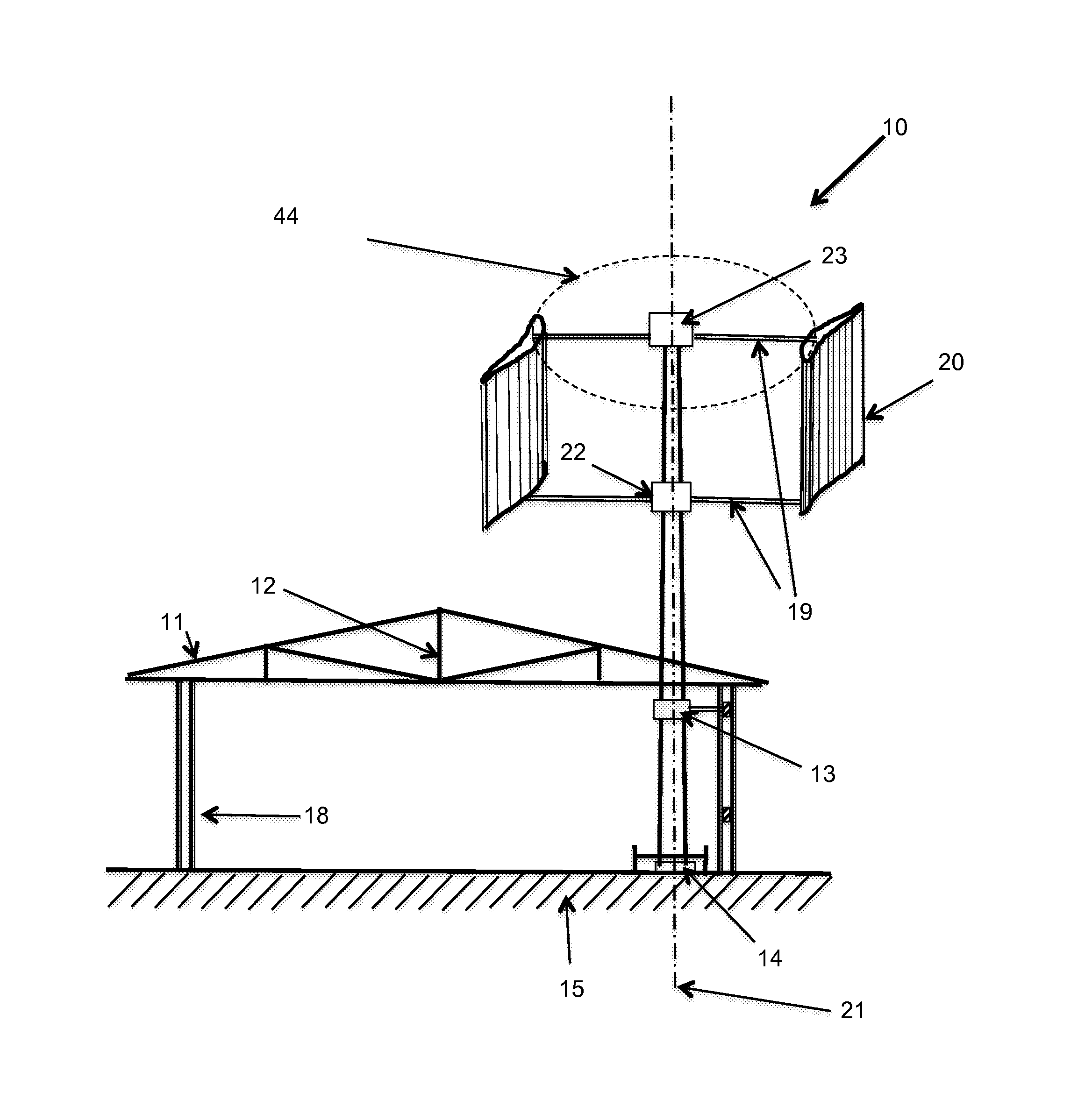

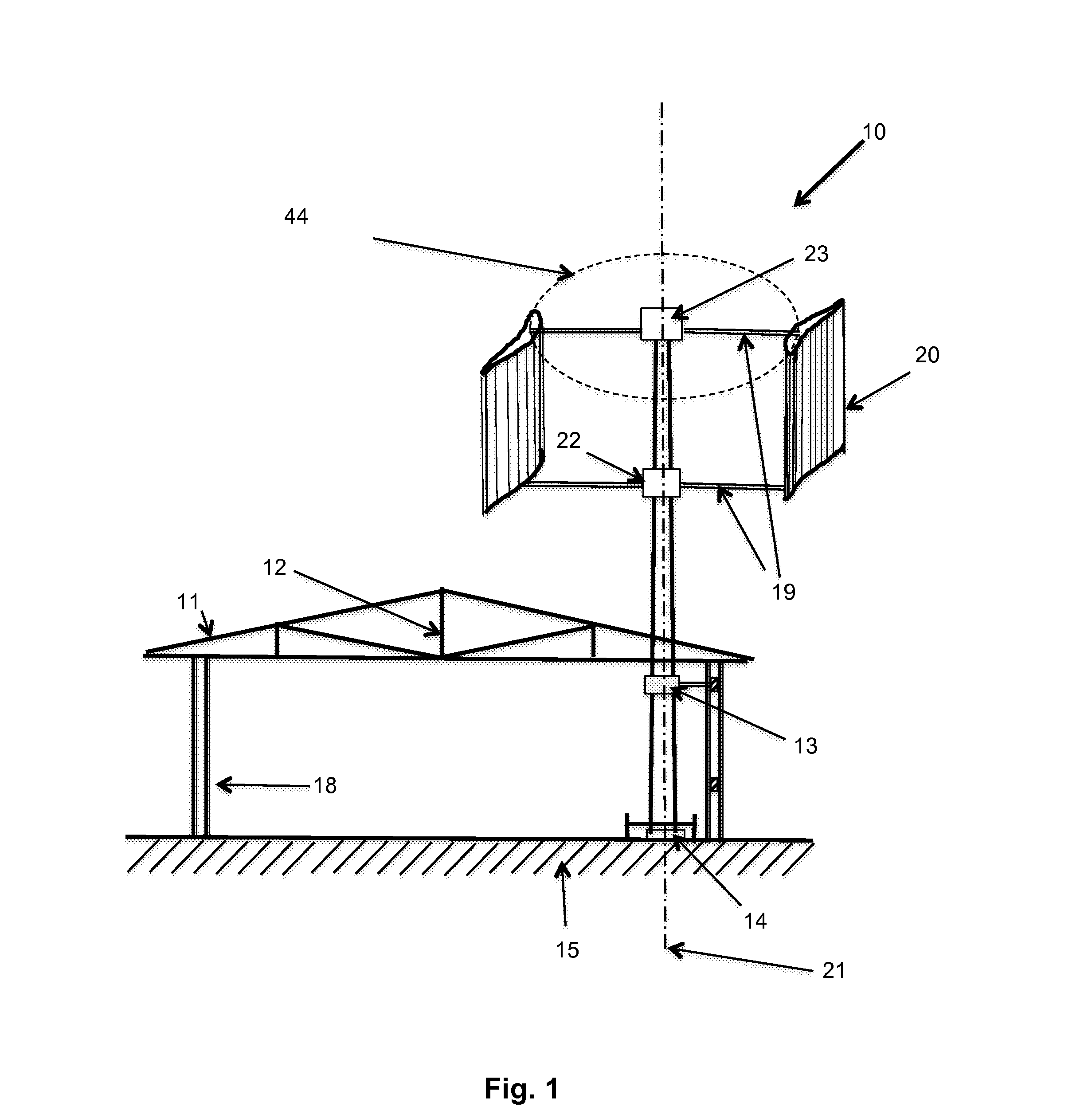

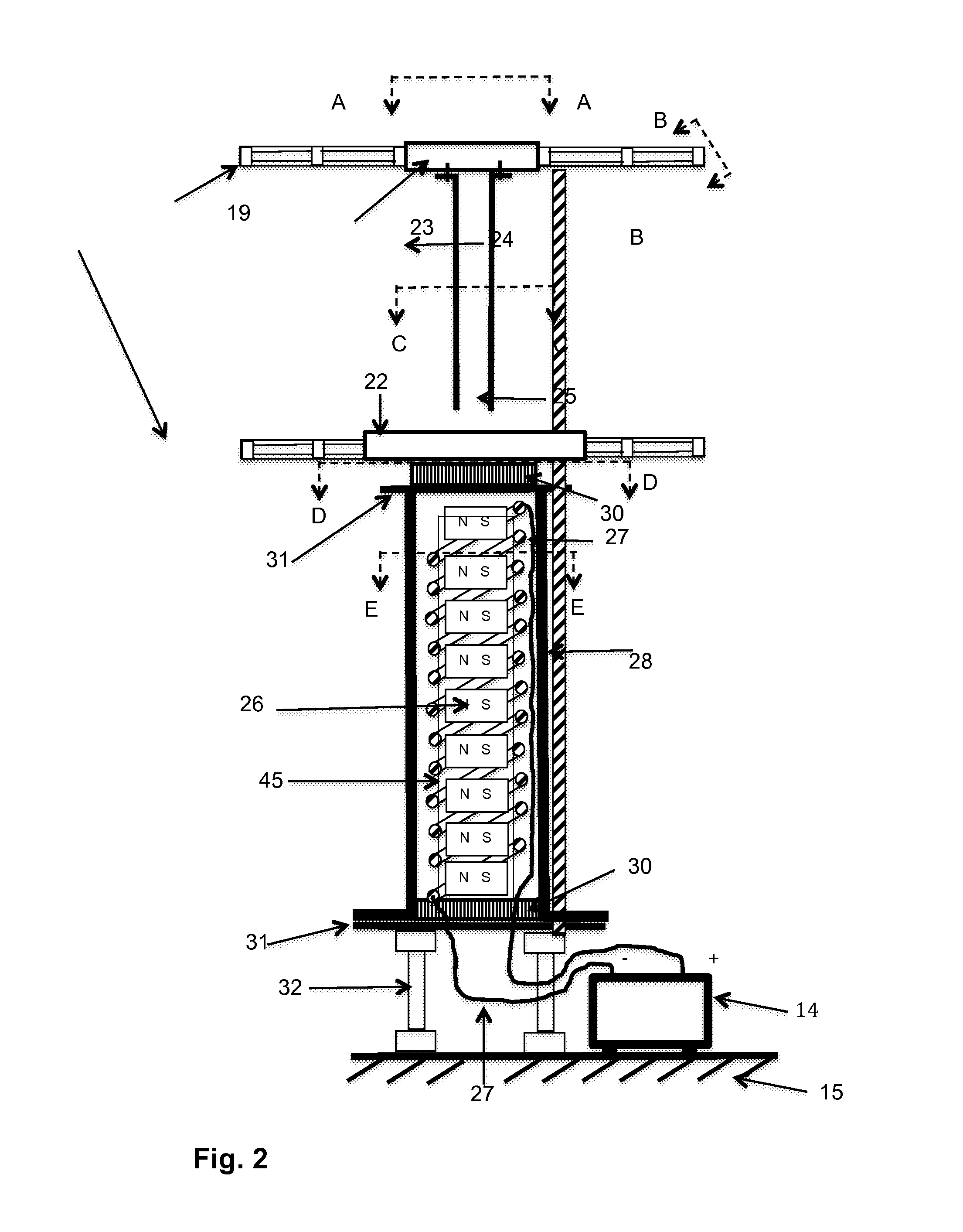

Hybrid Vertical Axis Wind Turbine

a wind turbine and vertical axis technology, applied in the direction of electric generator control, renewable energy generation, greenhouse gas reduction, etc., can solve the problem of low life-cycle cost, and achieve the effect of high starting torque, simple construction and high torqu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

1. DEFINITIONS

[0033]A Savonius type VAWT as used here are primarily drag type devices in which thrust produced in the wind collectors being pushed downwind is higher than the drag generated by the other collectors travelling upwind. As a result, a net trust is resulted that causes turbine to rotate. Betz's research indicated that for an airfoil operating on drag concept, only about 15% of the available energy from wind can be harnessed.

[0034]A Darrieus type VAWT is a wind turbine where a number of blades are used that produce lift force to generate electricity. In order to get higher lift force, the path difference between top and bottom streamlines should be as large as possible. The other factor that will influence the magnitude of the lift force is how smoothly the path difference is created. It is also possible to have a profile with large path difference between top and bottom surfaces and still can generate low lift forces. Wind tunnel tests were performed to determine the mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com