Method and system for monitoring the functionality of electrolysis cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

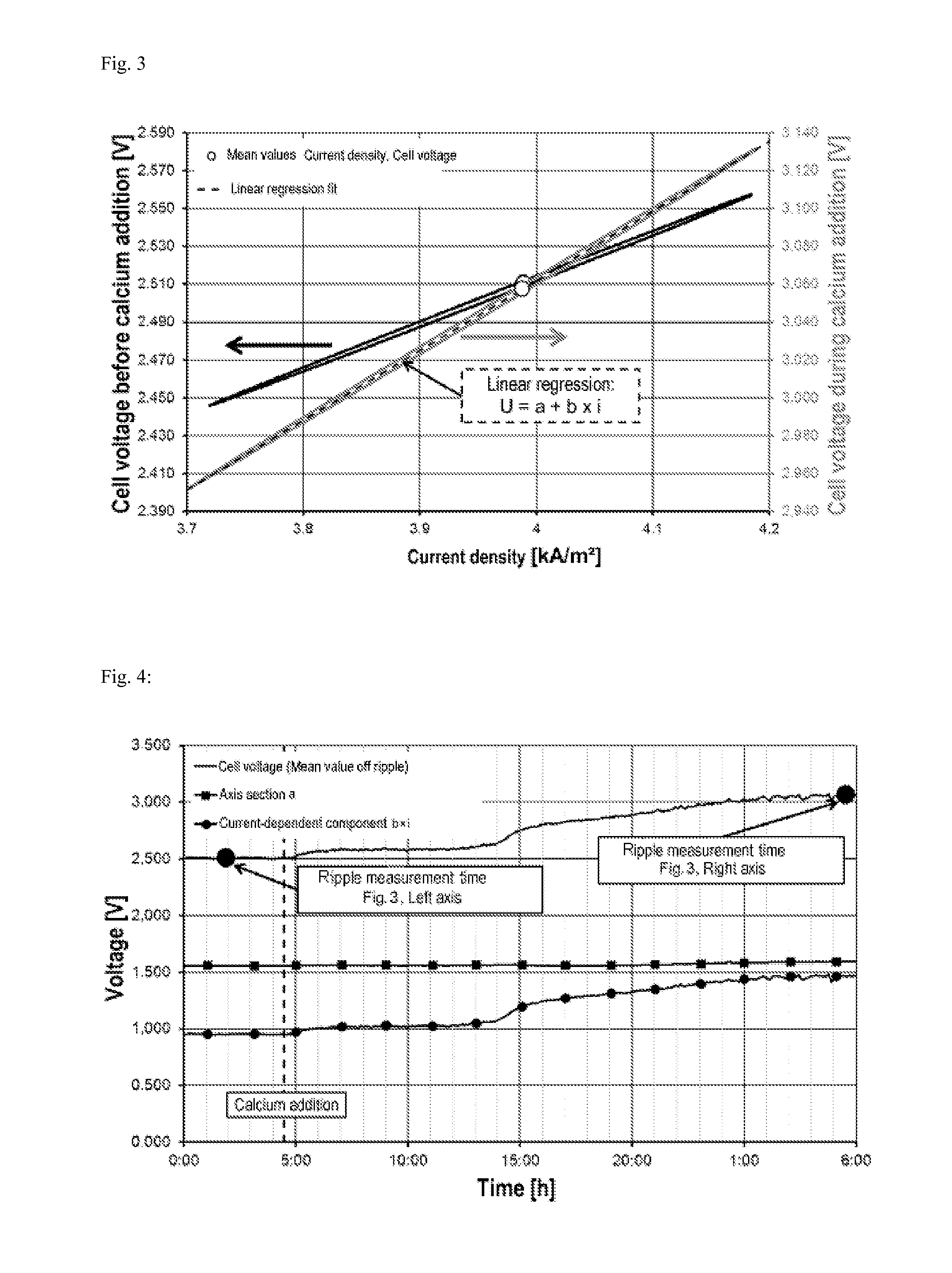

[0095]The examples describe the novel method for monitoring industrial electrolysis single cells for two experimentally simulated malfunctions in detail.

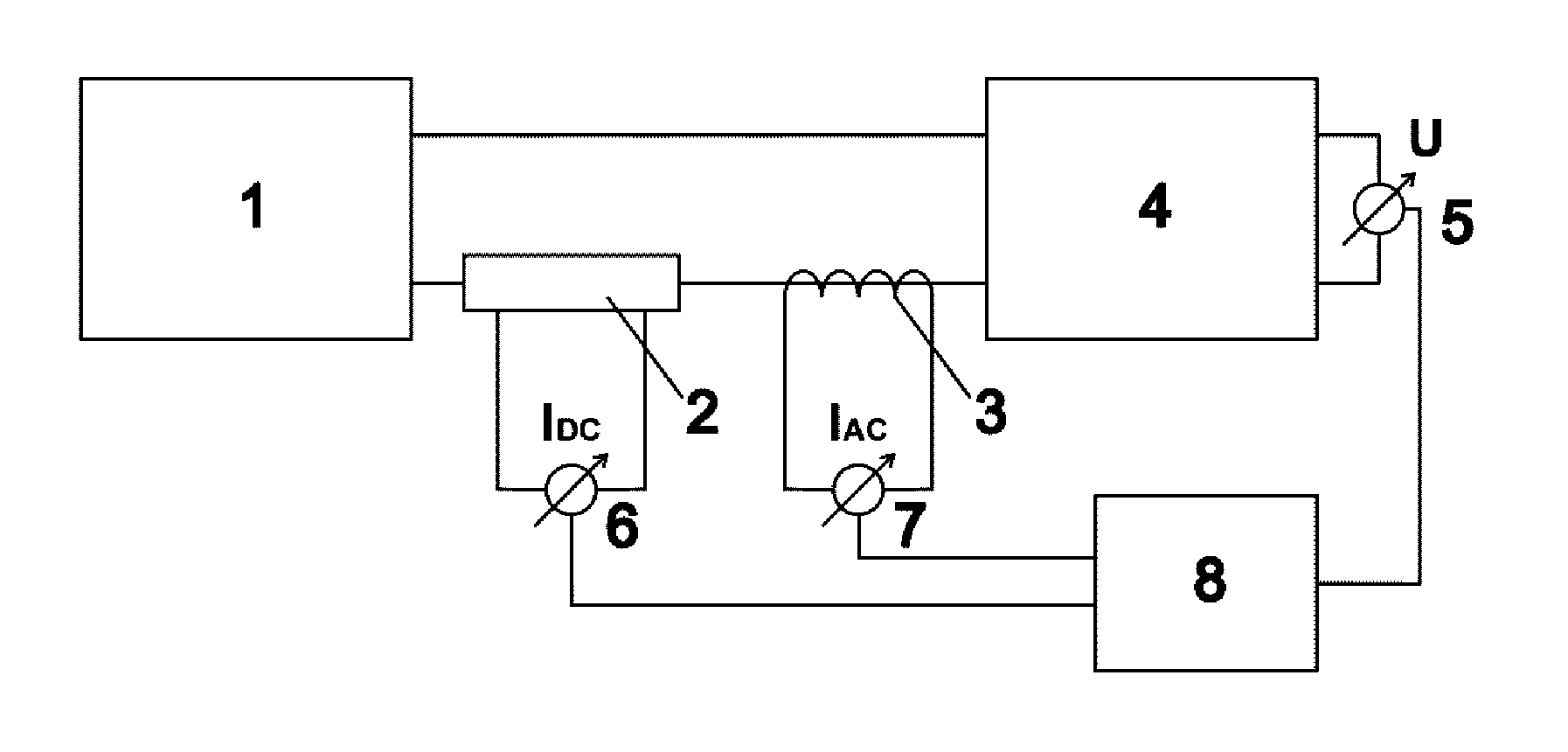

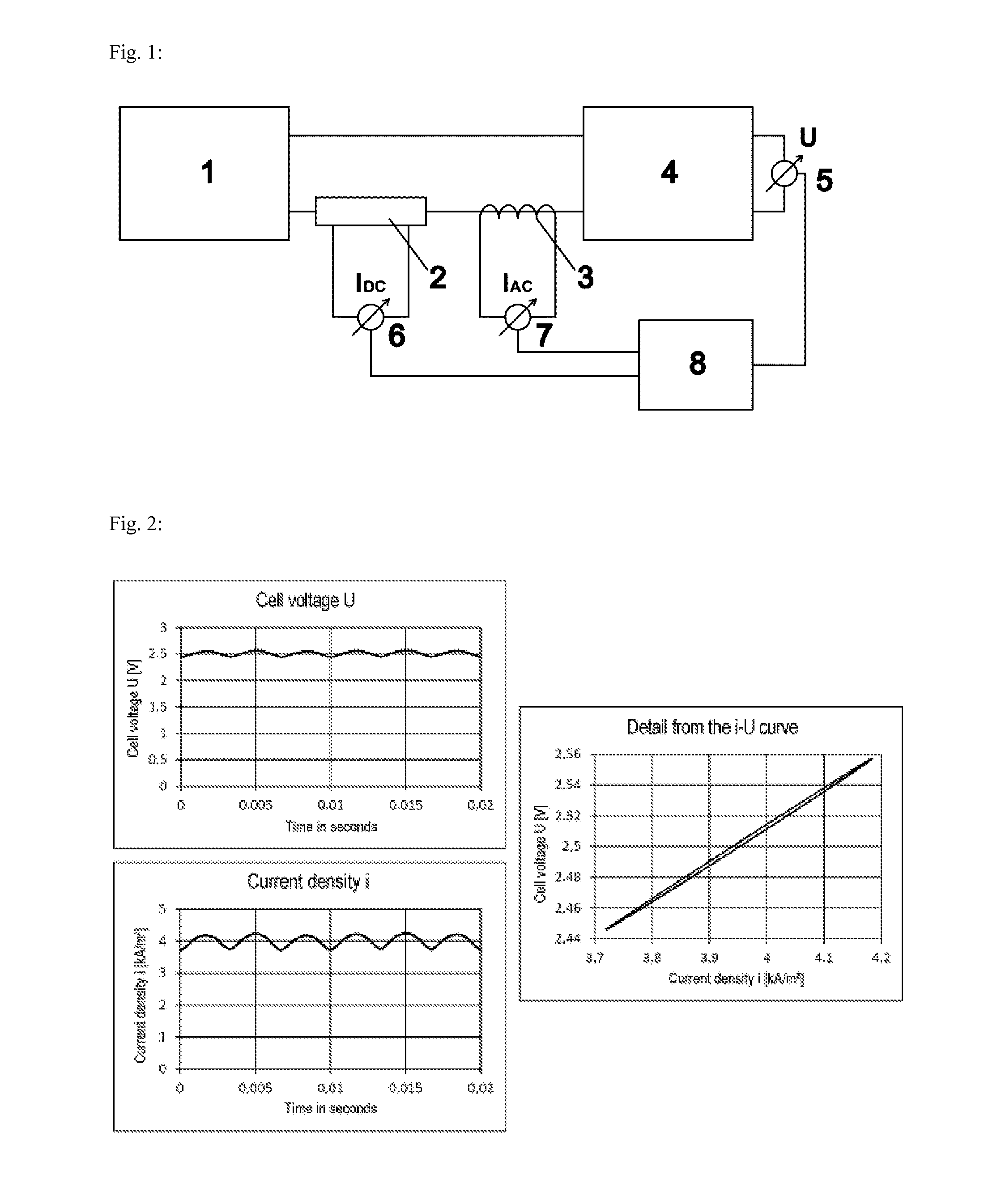

[0096]In this case, the dynamic current-voltage characteristic of the single cells is analyzed for the monitoring. It results from the reaction of the cell 4 to the periodic alternating current signal, which is present as a harmonic wave of the direct current as a result of the ripple of the rectifier 1 in many industrial electrolysis facilities.

[0097]FIG. 1 shows the measurement construction in principle. Due to the ripple, the current I, with which the electrolysis cell 4 is supplied by the rectifier 1, is not constant but rather oscillates periodically by a small amount. This minimal current change also has an effect on the electrolysis cell 4, which reacts with periodic changes of the cell voltage U. The idea of the measurement concept is that the time curve of both the current and also the cell voltage is detected and by compar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Frequency | aaaaa | aaaaa |

| Current | aaaaa | aaaaa |

| Electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com