Wine Decanter

a decanter and wine technology, applied in the field of wine sets, can solve the problems of increasing the stress of drinking wine, time-consuming and complex decanting process, and wine is always under mild shaking state, so as to save a large amount of decanting time and achieve rapid decanting. , the effect of increasing the pressur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]In order to more clearly describe the purposes, the technical proposals and advantages of the invention, the invention, with the combination of drawings, is further described in details in the followings.

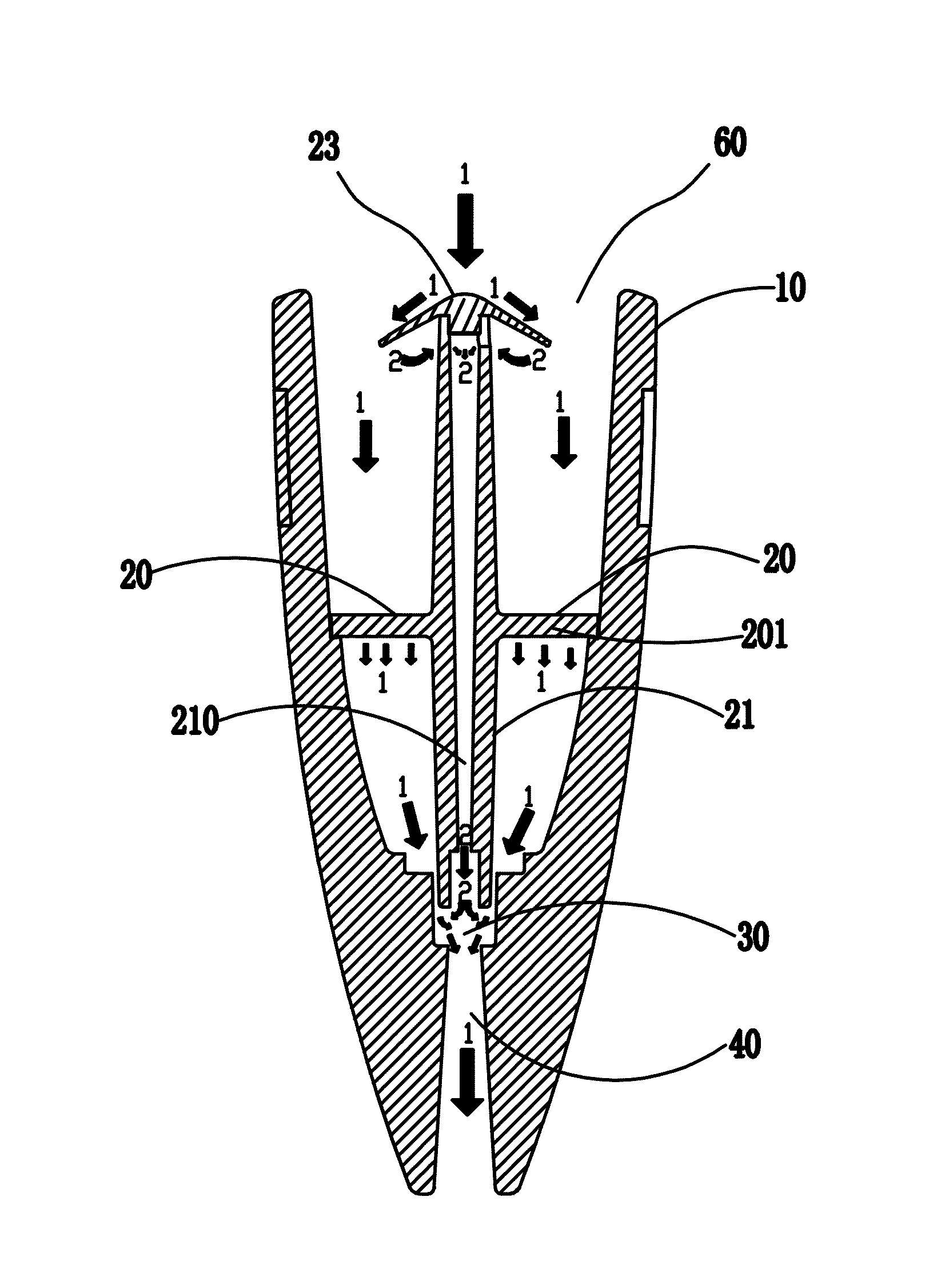

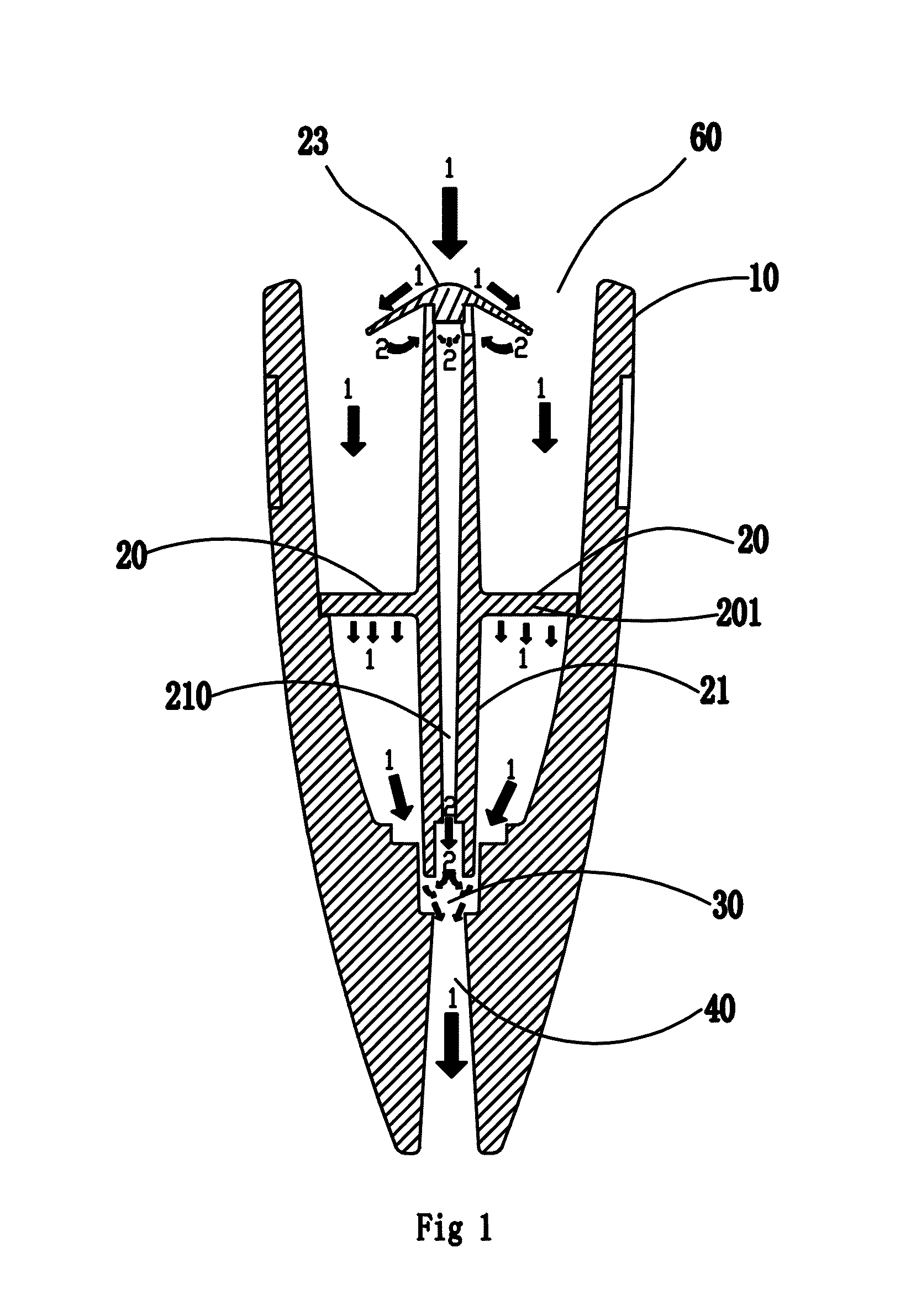

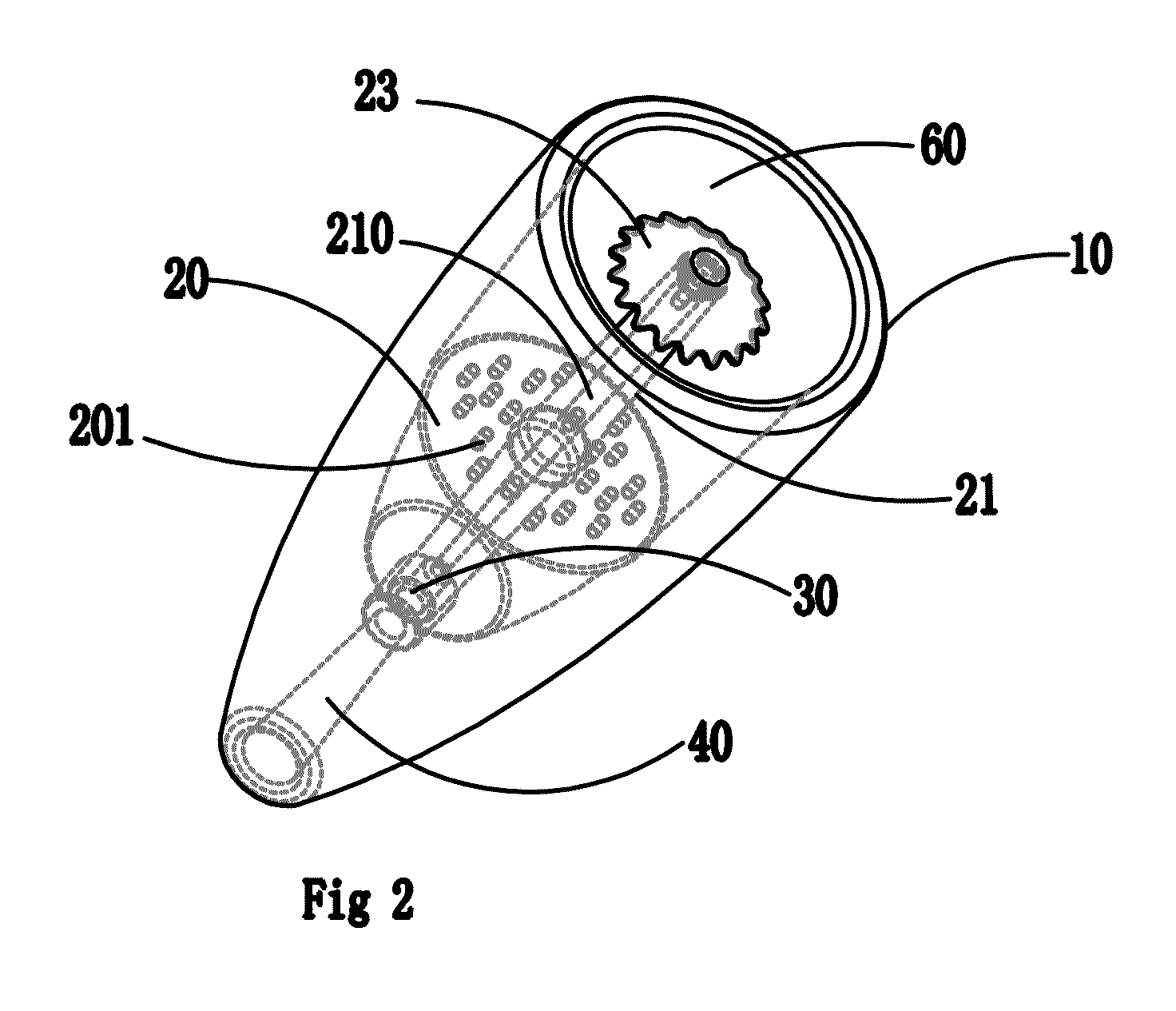

[0022]Referring to FIGS. 1-4, as shown in the figures, a novel wine decanter of an example of the invention comprises: a body 10 of a wine decanter 10 made of transparent organic glass or acrylic, a wine feeding funnel 60 being wide at the top and narrow at the bottom and successively opened along the upright direction of the center of the body 10 of the wine decanter, and a mixing cavity 30 designed from an extending part of the bottom end of the wine feeding funnel 60. The extending part of the bottom end of the mixing cavity 30 is designed as a wine discharge funnel 40 being wide at the top and narrow at the bottom. The wine feeding funnel 60, the mixing cavity 30 and the wine discharge funnel 40 pass through the whole body 10 of the wine decanter. The central axes of the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| transparent | aaaaa | aaaaa |

| sales volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com