Axial Compressor

a compressor and axial technology, applied in the direction of efficient propulsion technologies, machines/engines, liquid fuel engines, etc., can solve the problems of degrading affecting the reliability of the variable stator vane device, and not very much thought given to improving sealing performance. , to achieve the effect of improving the reliability of the axial compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

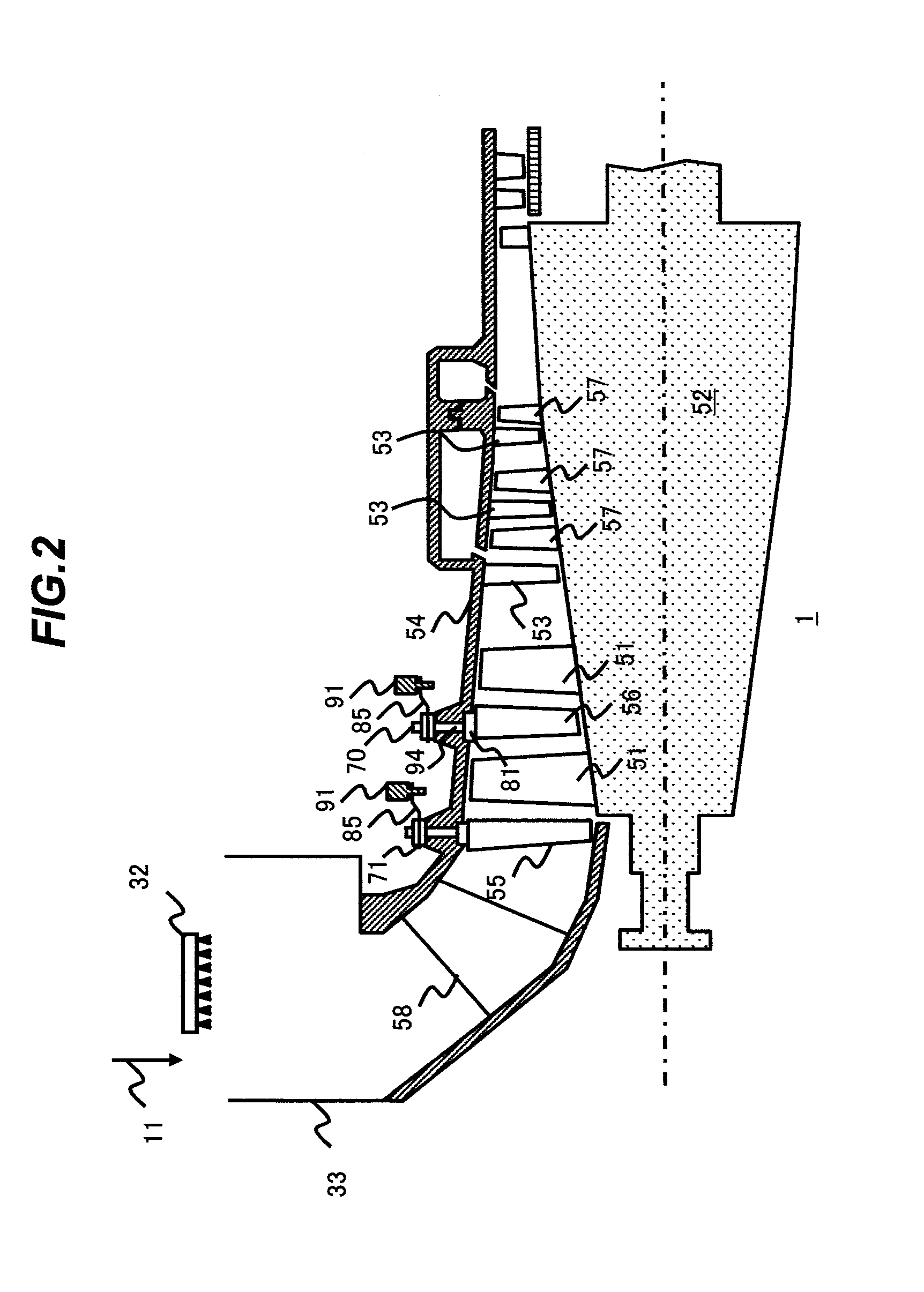

[0041]A detailed structure of the variable stator vane 56 in the compressor according to the present invention will be described below with reference to FIG. 3. In FIG. 3, the variable stator vane 56 includes the vane section 72, the stator vane base 81, the stem section 94, and a bolted stem section 89. Preferably, the vane section 72, the stator vane base 81, the stem section 94, and the bolted stem section 89 are integrally molded using, for example, casting.

[0042]The stem section 94 has a cylindrical shape and is inserted in a cylindrical through hole 73 formed radially relative to the casing 54. The stem section 94 assumes a rotational shaft of the variable stator vane 56. Rotating the stem section 94 about an axial center thereof varies the angle of attack of the vane section 72.

[0043]In the example shown in FIG. 3, the stem section 94 is inserted in the through hole 73 in the casing 54 after a thrust washer 82 is inserted. The thrust washer 82 is disposed between the stator v...

second embodiment

[0068]The configuration in the second embodiment results in the wear-resistant coating surface disposed on the side of the thrust washer 82 adjacent to the stator vane base 81 being in contact with the sealing member 92. This reduces the likelihood that the sealing member 92 will be worn and damaged, so that a risk of occurrence of drain can be reduced. The configuration also minimizes friction of the sliding portion between the sealing member 92 and the thrust washer 82, which allows accuracy in the opening degree of the variable stator vane to be maintained.

[0069]The first and second embodiments have been described with reference to FIGS. 3 and 4. The sealing groove 93 may still be formed in both the stator vane base 81 and the inner peripheral surface of the casing 54 so that the sealing member 92 can be mounted in both the surface on the inside and the surface on the outside in the rotor radial direction of the thrust washer 82.

[0070]In the first and second embodiments, the thru...

third embodiment

[0074]When the sealing member 92 is to be replaced with a new one in the compressor shown in FIG. 3 or 4, access to the sealing member 92 can only be gained after the variable stator vane 56 or 56A is removed from the inner peripheral side of the casing 54, which makes it necessary to disassemble the casing 54. As a result, the sealing member 92 is replaced only at a periodic inspection of the gas turbine. The configuration however, enables the sealing member 92B to be removed from the outside of the casing 54. Thus, when the sealing member 92B is worn and damaged, the sealing member 92B can be replaced with a new one without having to disassemble the casing 54. This improves maintainability.

[0075]Each of the first to third embodiments of the present invention described heretofore can prevent leakage of droplets occurring from the sliding portion of the variable stator vane in the axial compressor that has the intermediate cooling effect from spraying of the droplets over the intak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com