Hybrid Work Machine and Method of Controlling Auto-Stop of Engine for the Same

a hybrid work machine and engine technology, applied in the direction of hybrid vehicles, process and machine control, etc., can solve the problems of high increased operating temperature of devices equipped in vehicles, so as to achieve high temperature operation, reduce capacitance, and improve charging/discharging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

[0040]Exemplary embodiment(s) of the invention will be described below with reference to the attached drawings.

Description on Hydraulic Excavator as a Whole

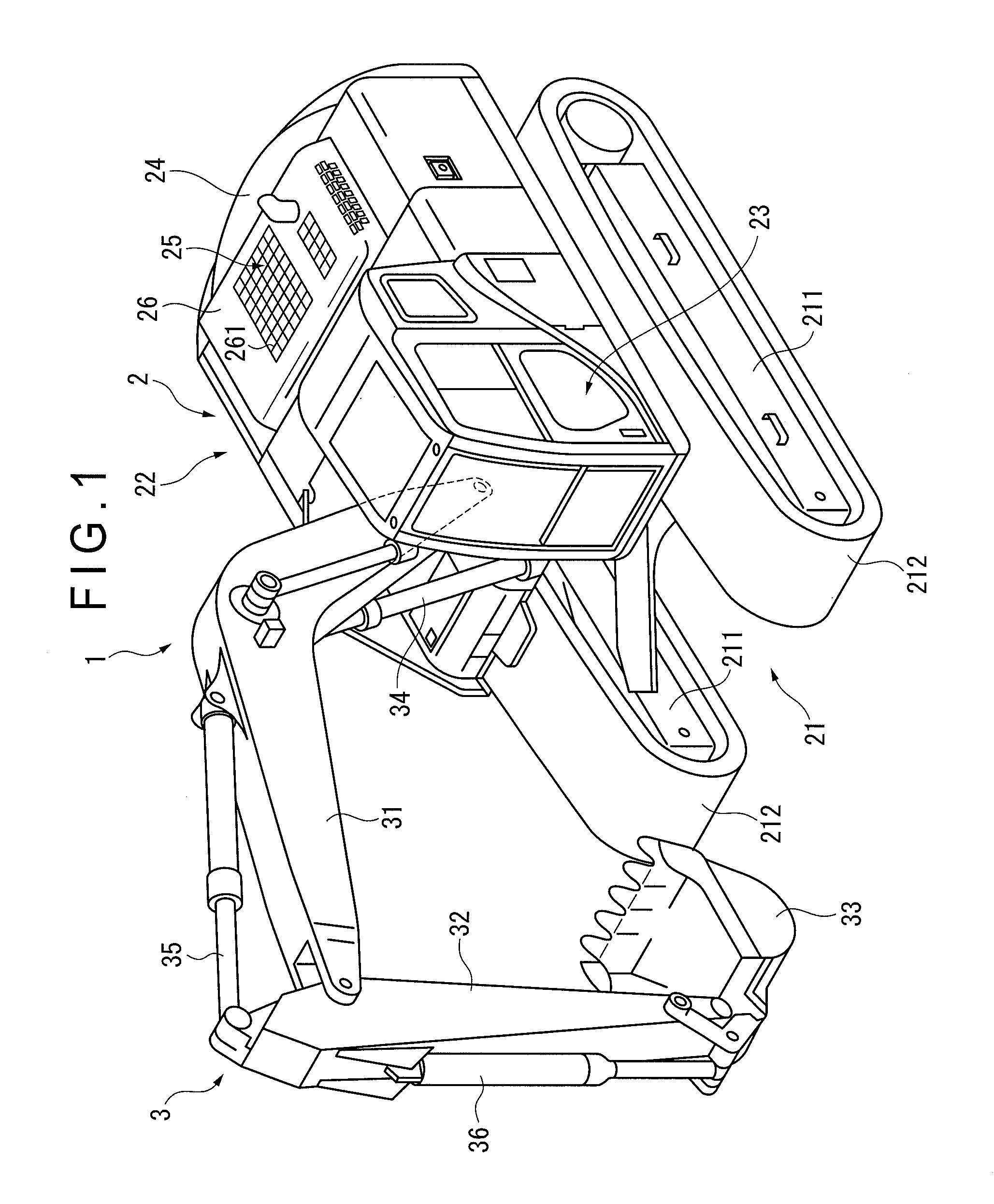

[0041]FIG. 1 shows a hybrid hydraulic excavator 1 as a hybrid work machine according to the exemplary embodiment. The hybrid hydraulic excavator 1 includes a vehicle body 2 and working equipment 3.

Vehicle Body

[0042]The vehicle body 2 includes a carrier 21 and a rotary body 22 rotatably provided on the carrier 21. The carrier 21 includes a pair of traveling devices 211. The respective traveling devices 211 are provided with crawler belts 212. Later-described hydraulic motors 213R, 213L drive the crawler belts 212, whereby the hybrid hydraulic excavator 1 travels.

Rotary Body

[0043]The rotary body 22 includes a cab 23, a counterweight 24 and an engine compartment 25. The counterweight 24 is provided for weight balance with the working equipment 3 and is filled with weights. An engine hood 26 covering the engine compartment 25 has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com