Wavelength conversion layer on a glass plate to enhance solar harvesting efficiency

a technology of solar energy and conversion layer, which is applied in the field of wavelength conversion device, can solve the problems of wavelengths below 514 nm to be absorbed, inability to effectively utilize the entire spectrum of light, and loss of radiative energy to the device itself, and achieve the effect of enhancing solar harvesting efficiency and high efficiency conversion of wavelengths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0130]The embodiments will be explained with respect to preferred embodiments which are not intended to limit the present invention. In the present disclosure, the listed substituent groups include both further substituted and unsubstituted groups unless specified otherwise. Further, in the present disclosure where conditions and / or structures are not specified, the skilled artisan in the art can readily provide such conditions and / or structures, in view of the present disclosure, as a matter of routine experimentation.

a) Synthesis of Chromophore Compounds

[0131]The down-shifting chromophore compounds may be synthesized according to the methods described in U.S. Provisional Patent Application Nos. 61 / 430,053, 61 / 485,093, 61 / 539,392, and 61 / 567,534.

b) Wet Process Synthesis of WLC on Glass Plate

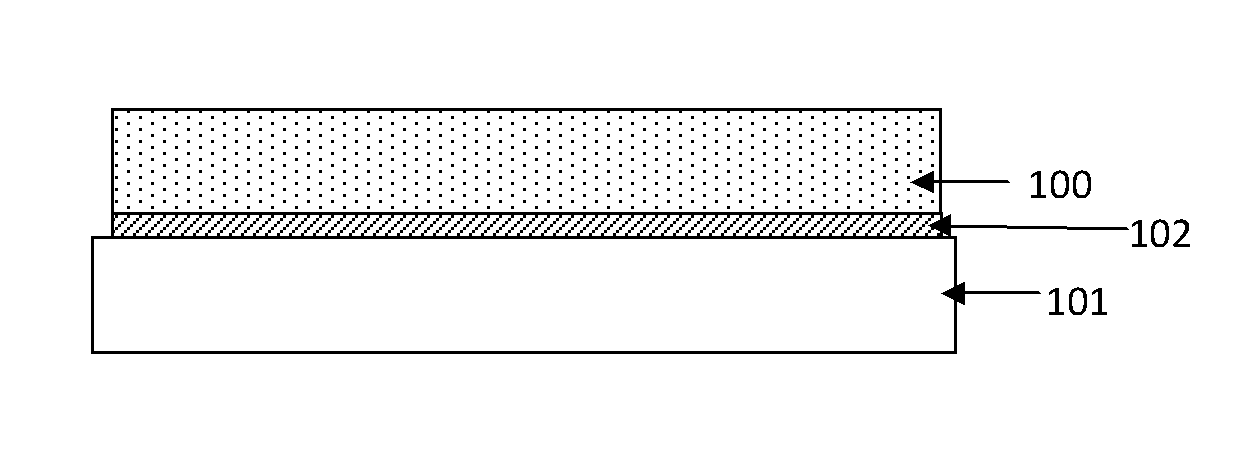

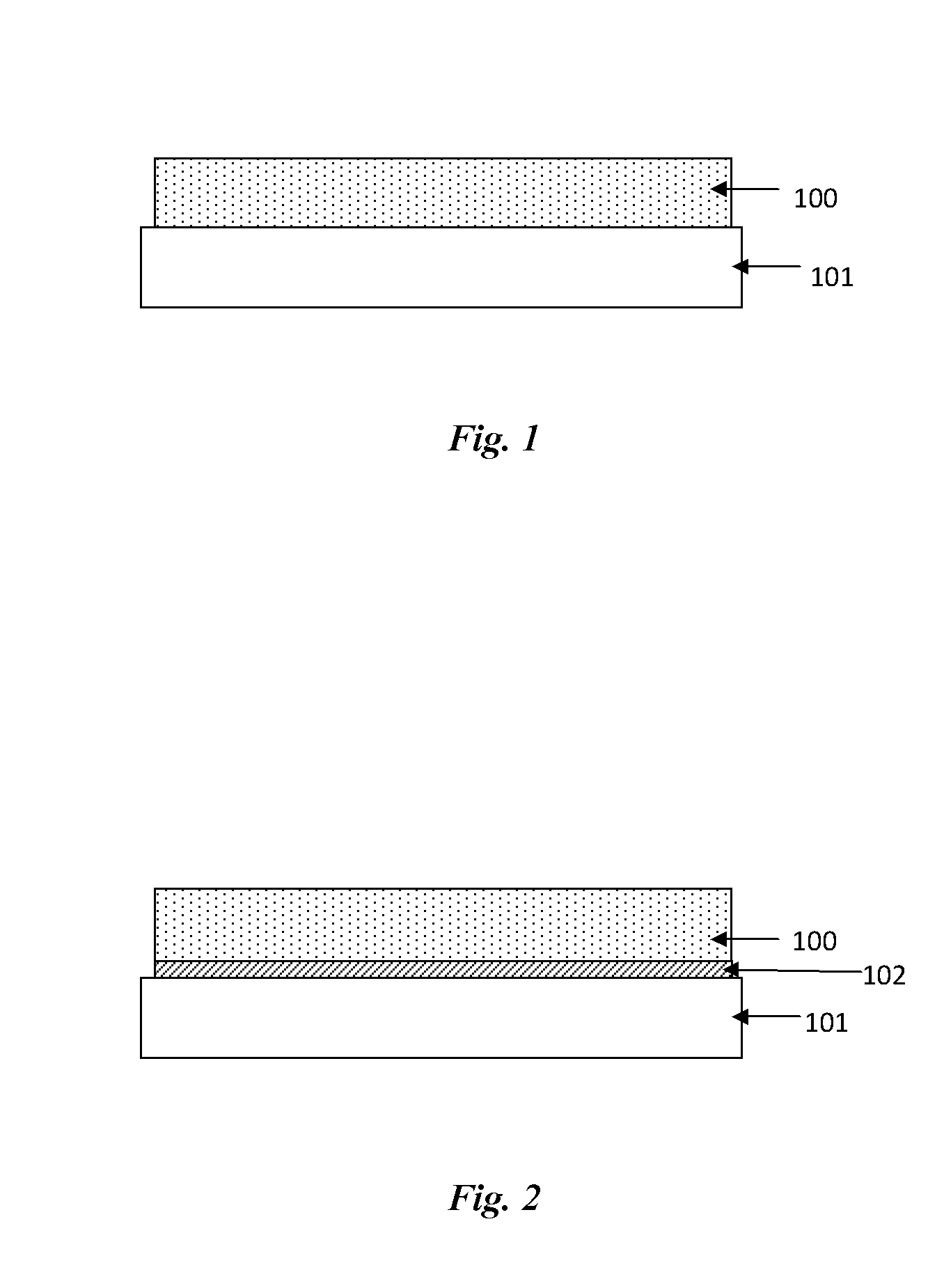

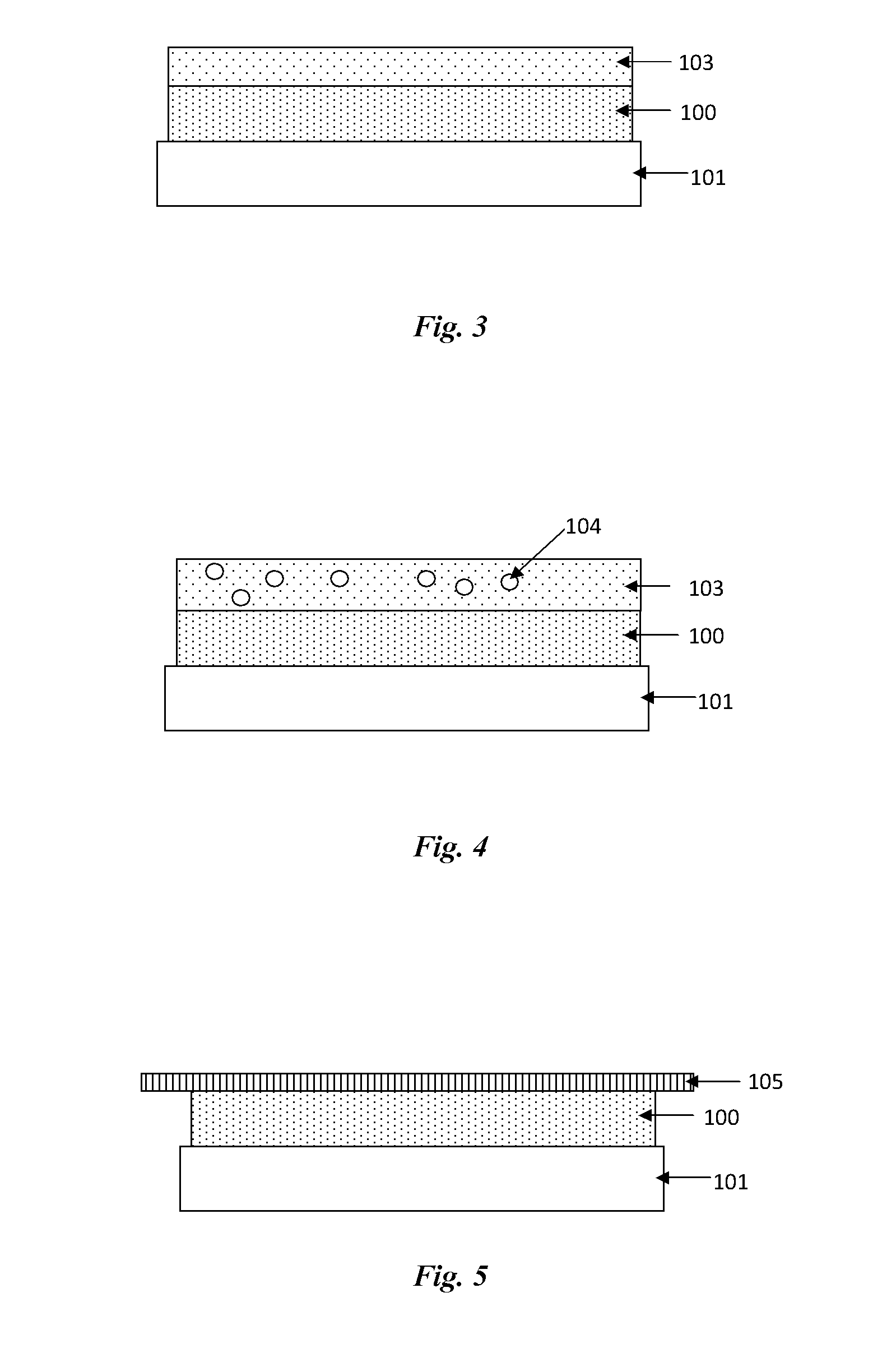

[0132]In several embodiments, a wavelength conversion layer 100, which comprises at least one chromophore, and an optically transparent polymer matrix, is fabricated onto a glass plate. The wave...

example 2

[0137]Example 2 followed the same procedure as given in Example 1 steps a-d, except that a dry processing technique was used to fabricate the wavelength conversion layer as defined below.

b) Dry Process Synthesis of a WLC on Glass Plate

[0138]In several embodiments, a wavelength conversion layer 100, which comprises at least one chromophore, and an optically transparent polymer matrix, is fabricated onto a glass plate using a dry processing technique.

[0139]The wavelength conversion layer is fabricated by (i) mixing PVB powders with the chromophore at a predetermined ratio of 0.3% by weight in a mixer at 170° C.; (ii) degassing the mixture between 1-8 hours at 150° C.; (iii) then forming the layer using an extruder or hot press at 120° C.; (iv) the layer thickness was 250 μm which was controlled by the extruder. Once the wavelength conversion layer is formed it is then laminated onto a ˜3 mm thick glass plate using a laminator.

[0140]The efficiency enhancement of the Example 2 structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com