Emulsifier for Lubricating Oil Concentrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

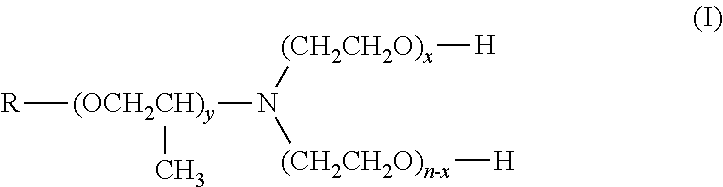

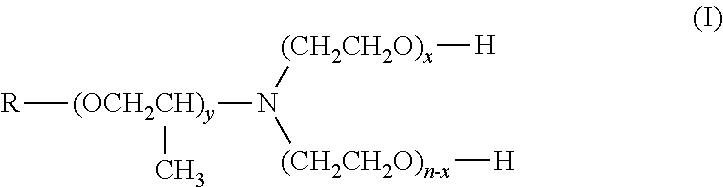

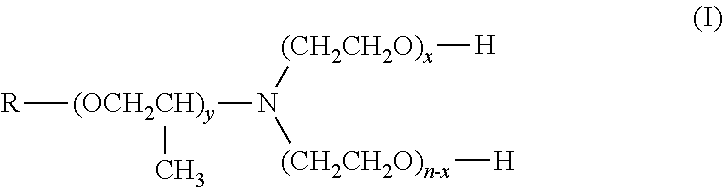

Method used

Image

Examples

example 1

[0049]Emulsifying properties and foam resistance were evaluated for four different commercially available sodium sulfonate (M, H, HL, and L) emulsifiers and an ethoxylated ether amine according to the present disclosure (Surfonic® PEA-25 emulsifier available from Huntsman Petrochemical LLC). The oil concentrates were prepared by adding each emulsifier at various dosages (5 wt. %, 8 wt. %, and 12 wt. % of emulsifier, based on the total weight of the oil concentrate) to a base oil (paraffin-base oil).

[0050]5.0 grams of the resulting oil concentrate and 95.0 grams of deionized water were then added to a graduated cylinder. The cylinder was stoppered, shook, and various properties were then measured. The results are given below in Table 1 through 3.

Materials Used for Example 1:

[0051]

EmulsifierSodium SulfonateMaterial NameAristonate ® MAristonate ® HPetronate ® HLPetronate ® LAverage430460450420MolecularWeightMaterial TypeSyntheticNaturalSupplierPilot Chemical Co.Sonneborn Inc.Paraffin-b...

example 2

[0052]Soluble Oil Formulation

[0053]The following oil concentrate formulation at about 5 weight parts to 10 weight parts per 100 parts of oil concentrate per 100 weight parts water was prepared. The emulsions performance was then measured and the results are provided in Table 4 below:

TABLE 4Wt. % based on the totalOil Concentrate Componentsweight of oil concentrate150N Paraffinic Oil 65%Diglycolamine4.7%Boric Acid2.6%Caprylic Acid1.4%Surfonic ® WT-2524 3%Surfonic ® PEA 25 14%Tall Oil Fatty Acid 8%Deionized Water1.3%Test ResultsAppearance (Concentrate)clearConcentrate StabilityHigh Temp@50° C., 4 HclearAppearance (Emulsion @ 5%)Milky whitepH @ 5%9.05Emulsion Stability @ 5%, 25° C.Oil / Cream, ml200 ppm Hard Waternone / Trace400 ppm Hard Waternone / 0.1

[0054]Semi-Synthetic Fluid Formulation

[0055]The following oil concentrate at about 5 weight parts to 20 weight parts of oil concentrate per 100 weight parts water provides excellent emulsion stability. No aluminum staining was observed.

Wt. %...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com