Chlorine dioxide generator for the efficient generation of chlorine dioxide in dilute solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

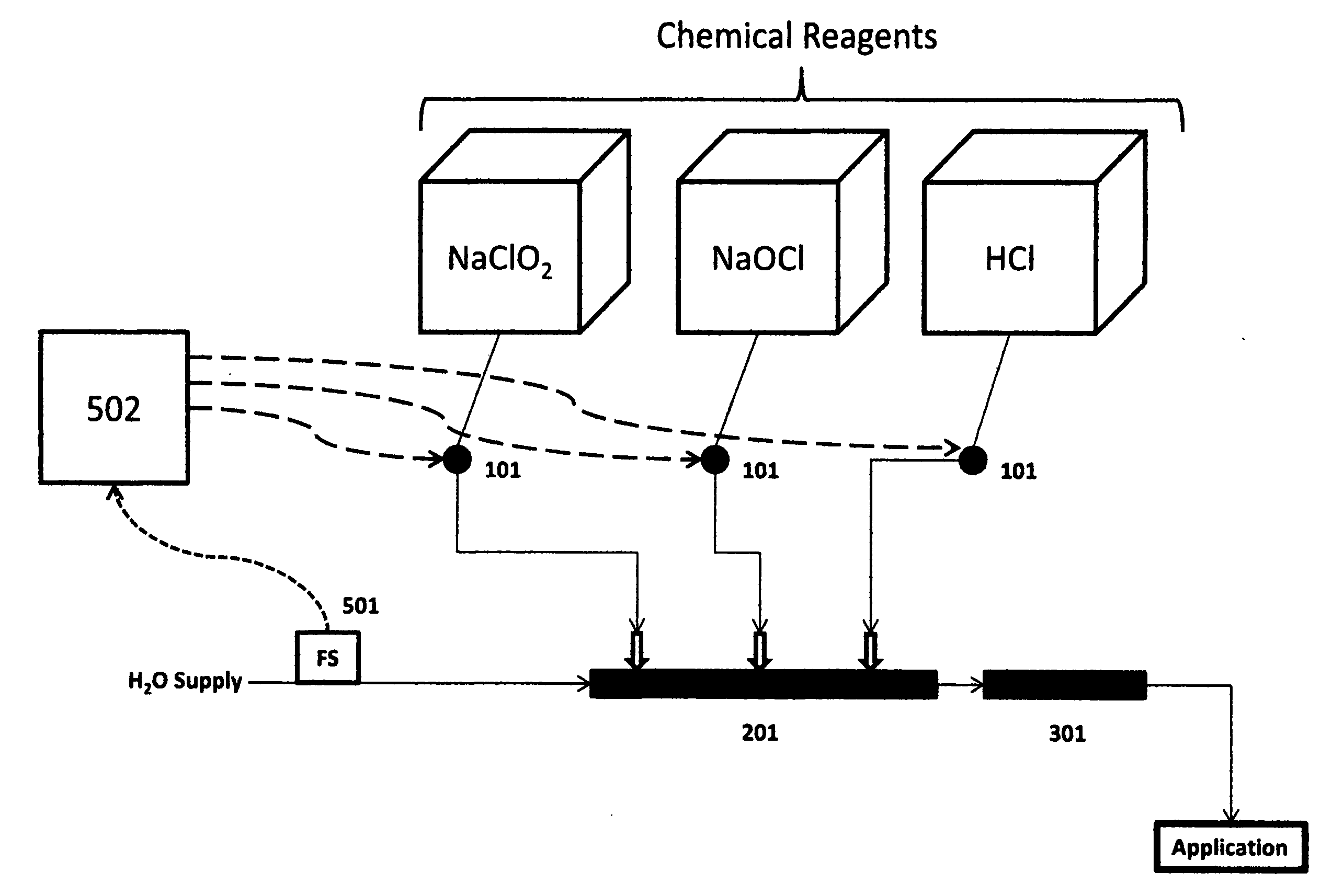

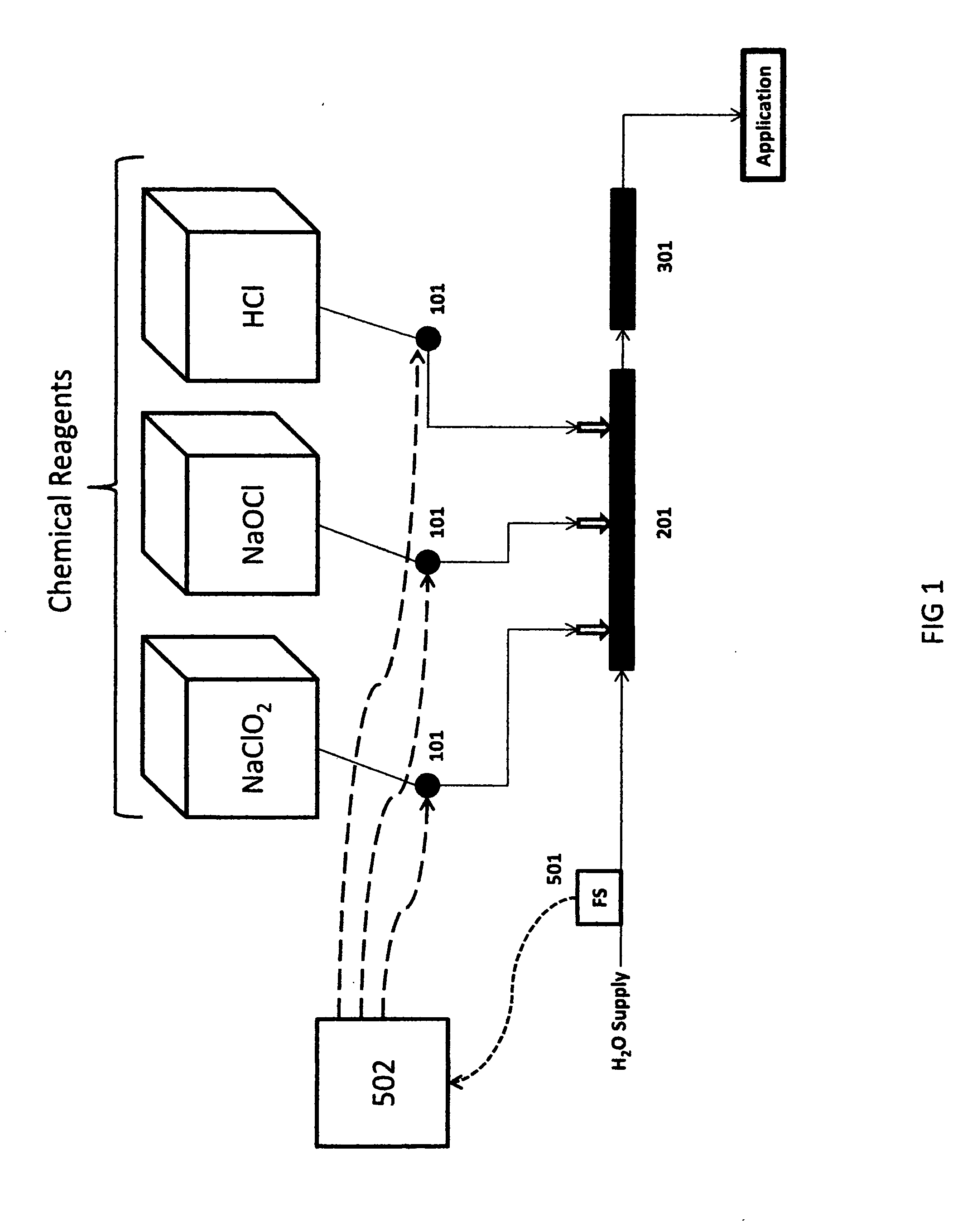

[0029]The invention is an apparatus and method for the safe and efficient generation of chlorine dioxide using chemicals (reagents) without producing a concentrate of chlorine dioxide. The invention comprises a plurality of chemical feed systems in fluid contact with an injection manifold flooded with water by a source of motive (flowing) water. The plurality of chemical feeds deliver chemicals for the generation of chlorine dioxide (reagents) comprising a source of acidified chlorine and a source of chlorite to produce a dilute aqueous solution of chlorine dioxide. The motive water, acidified chlorine, and chlorite anion flow through a reaction chamber and convert at least 80 wt %, more preferably 90 wt %, and most preferably 95 wt % of the chlorite anion to chlorine dioxide before being applied to the application.

[0030]In one preferred method the control panel actuates the chemical feed systems only when motive (flowing) water is confirmed using a flow sensor and a sufficient peri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Feed rate | aaaaa | aaaaa |

| Reduction potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com