Positive pressure ventilation in enclosed housings

a technology of enclosed housing and positive pressure, which is applied in ventilation systems, lighting and heating apparatus, heating types, etc., can solve the problems of reducing production, odor and moisture buildup in enclosed housings, etc., and achieves the effects of limiting entry of air-borne pathogens, preventing or minimizing entry of contaminated external air, and promoting ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Positive Pressure Ventilation of an Enclosed Housing

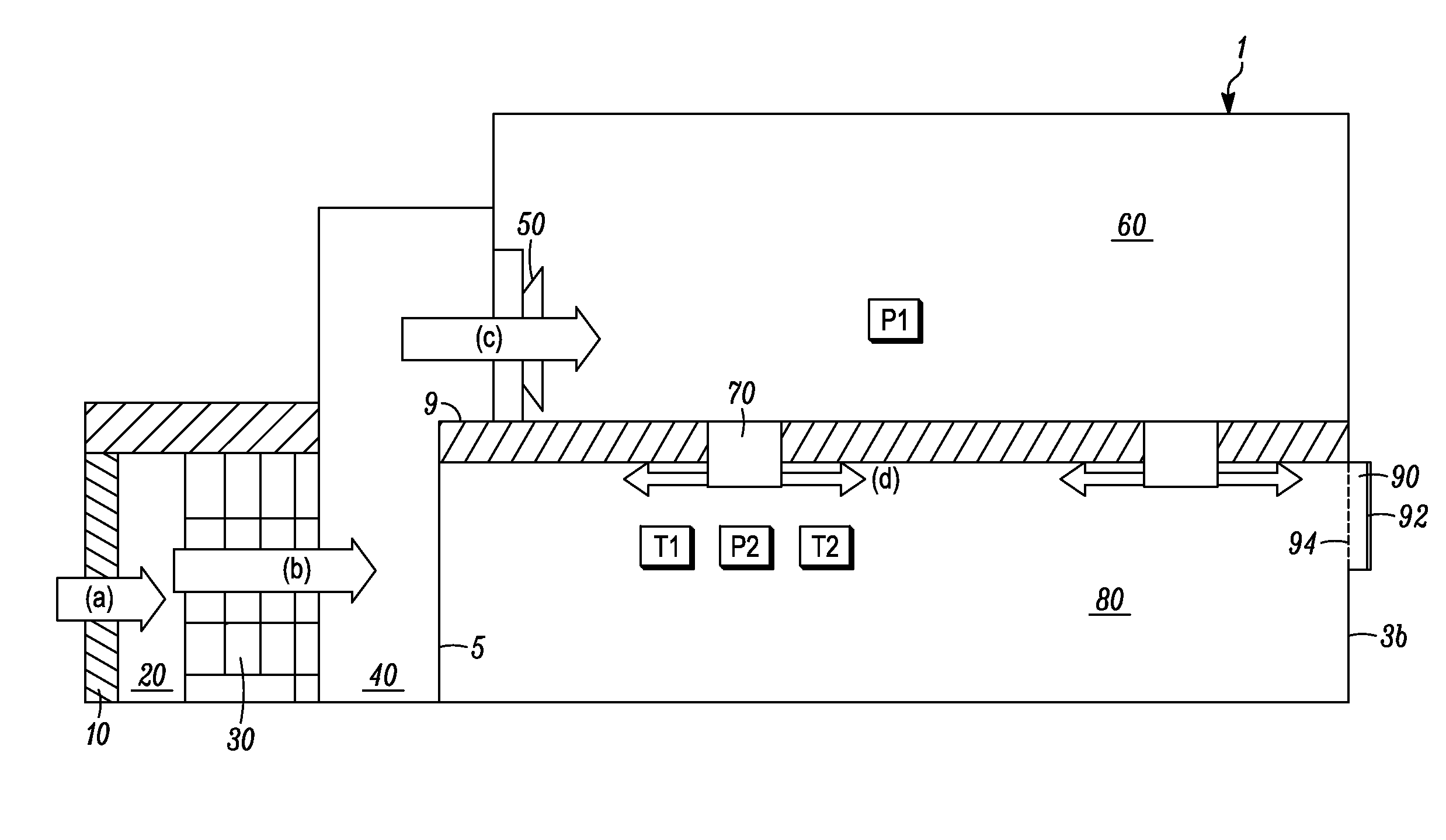

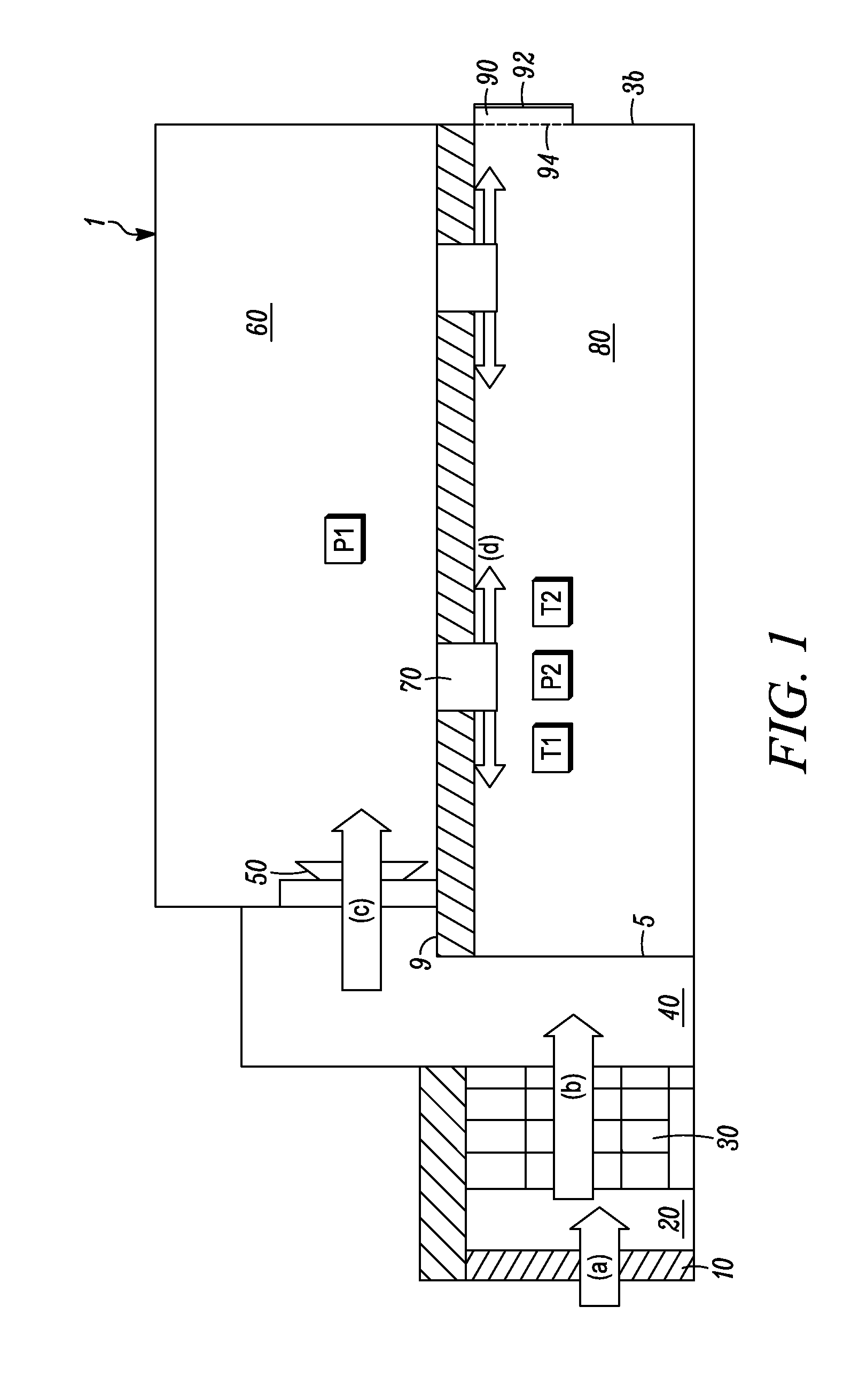

[0070]An embodiment of the invention is shown in FIG. 1, which provides a sectional view of an enclosed housing having a positive pressure ventilation system. In FIG. 1, housing 1 includes living chamber 80 at one level; overpressure chamber 60, a highly pressurized attic space in communication with living chamber 80 through interconnecting air passage 70; air chamber 40, which supplies cooled and filtered air to the one or more of fan 50; and air chamber 20, which contains air that has been cooled by passage through cooling wall 10.

[0071]The direction of airflow through housing 1, represented by the arrows (a), (b), (c), (d) and (e) in FIG. 1, is as follows: (a) external, unfiltered air at ambient temperature is cooled by cooling wall 10 during passage into chamber 20; (b) cooled air in chamber 20 is filtered as it passes through air filter wall 30 into chamber 40; (c) cooled and filtered air in chamber 40 is drawn into overpressu...

example 2

Positive Pressure End Wall Configuration

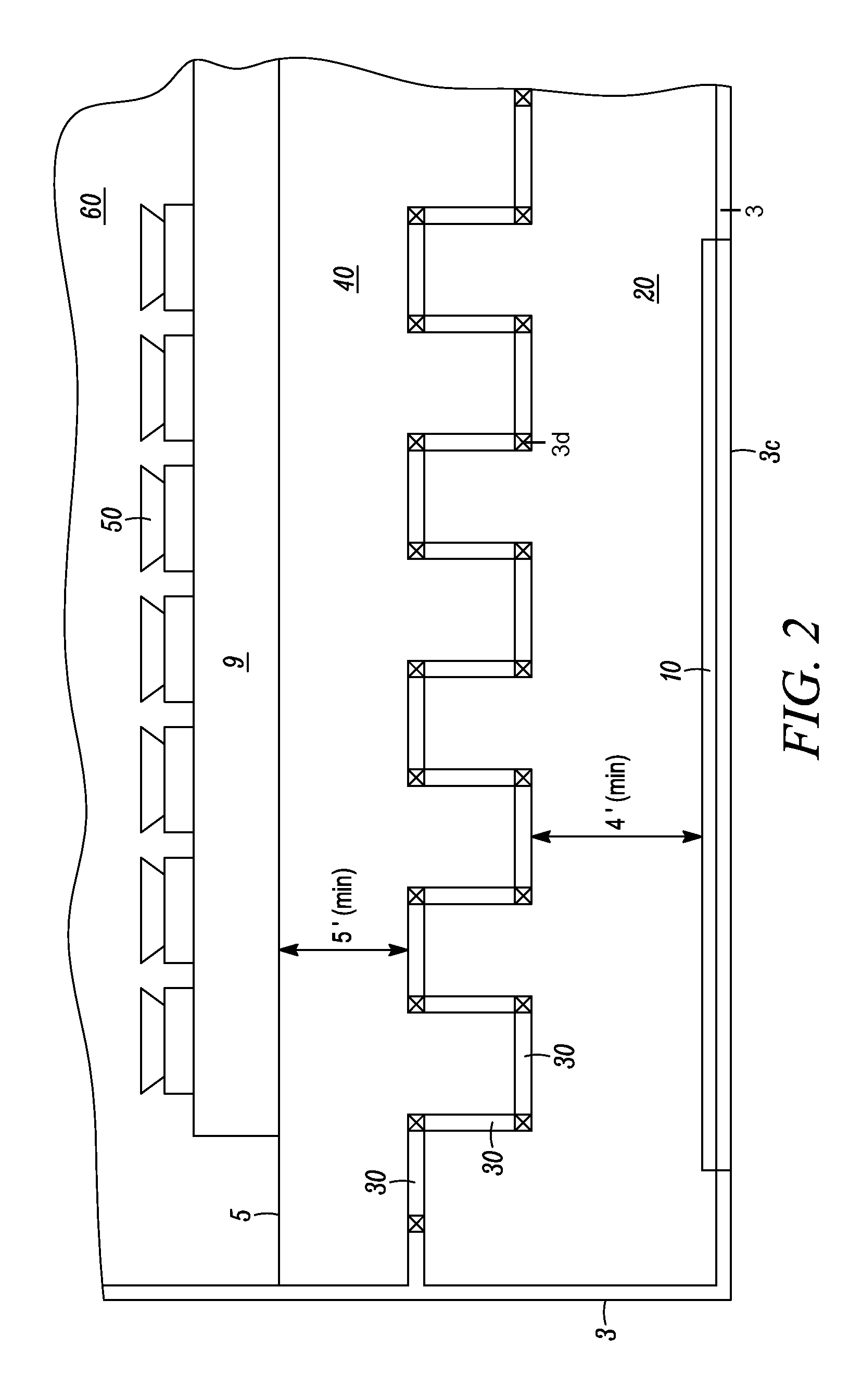

[0076]A diagram representing a partial plan view of an end wall configuration used in an embodiment of the invention is illustrated in FIG. 2. In this embodiment, a plurality of fan 50 for blowing air into overpressure chamber 60 is mounted to building end wall 5 adjacent fan access platform 9. Two air spaces, air space 40 and air space 20, separate the one or more of fan 50 from the exterior of the housing. Air space 40, which occurs between building end wall 5 and filter wall 30, supplies cooled and filtered air to the plurality of fan 50 for ventilation of overpressure chamber 60. Air space 20, which is between filter wall 30 and evaporative cooling wall 10, houses cooled air from the exterior of the housing. Cooling wall 10 separates cooled air in space 20 from the exterior of the housing. Filter wall 30, disposed between building end wall 5 and cooling wall 10, is formed using a plurality of filters arranged at least about five feet from ...

example 3

Exterior Wall Structure of a Living Chamber Outlet in a Positive Pressure Housing

[0078]Living chamber air outlet 90 for the egress of air from living chamber 80 is illustrated in FIG. 3A-3C. Outlet 90 is disposed above housing base wall 3b and includes damper 92 and shutter wall 94. Outlet damper 92 is a 48-inch roll seal or insulated curtain wall outlet damper mounted on the exterior side of the building outlet above base-wall 3. FIG. 3B, which provides a view of outlet 90 from the exterior of the building, shows the insulated curtain / roll seal outlet damper 92 half opened. Shutter wall 94 is a 45-inch ID Z Wall shutter wall located within the opening of outlet 90 above base-wall 3b to provide backdraft protection. FIG. 3C, which provides a view of outlet 90 from the interior of the building, shows that shutter wall 94 is coextensive with the opening of outlet 90, thereby providing an added barrier to infiltration of external air. Base wall 3b is a 48-inch insulated concrete or EPS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com