Hydraulic borehole mining system and method

a hydraulic and borehole technology, applied in the direction of borehole/well accessories, fluid removal, construction, etc., can solve the problems of inability to reduce the operating footprint and personnel, high energy requirements, and inability to reduce the pressure or fluid loss at the connection, so as to reduce equipment, energy and cost, and maximize the fluid flow efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

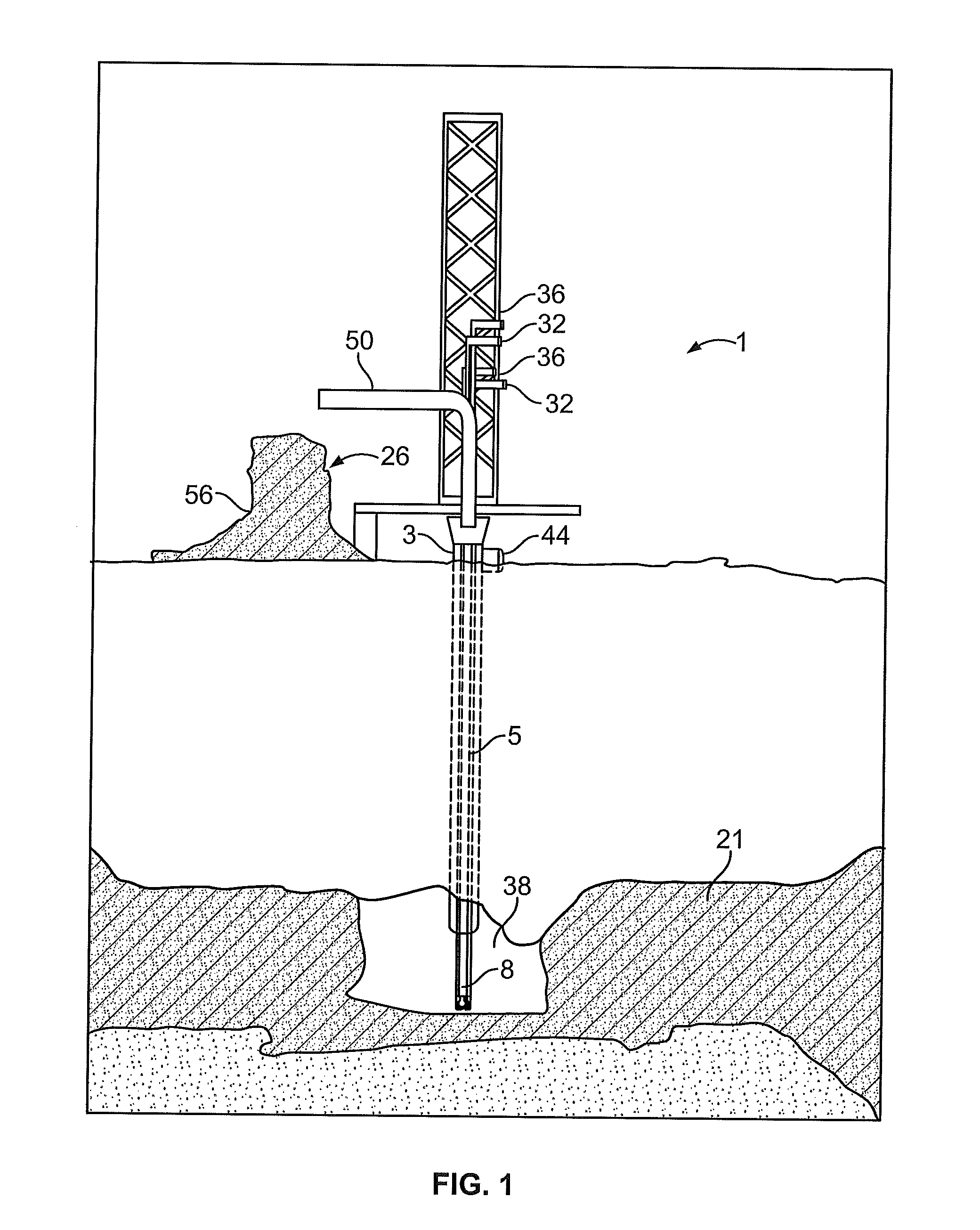

[0043]Referring now to FIG. 1, a system and a process of hydraulic borehole mining for a subterranean resource in accordance with the present invention is described in detail. A rig shown generally at 1 is brought to the site, situated at a preferred location at the site, and operated to drill a well (or wellbore, as the term is used in the art) to the top of the resource body. The wellbore may be drilled at any angle from vertical to horizontal depending upon the geotechnical mining conditions down-hole and the structure of the ore body itself. A casing string 3, if required, is then run into the initial bore and cemented into position to give strength to the wellbore. A conventional drill string is then fed into the casing string, and a pilot hole is drilled through the resource body. The conventional drilling string (not shown) is thereafter removed from the hole.

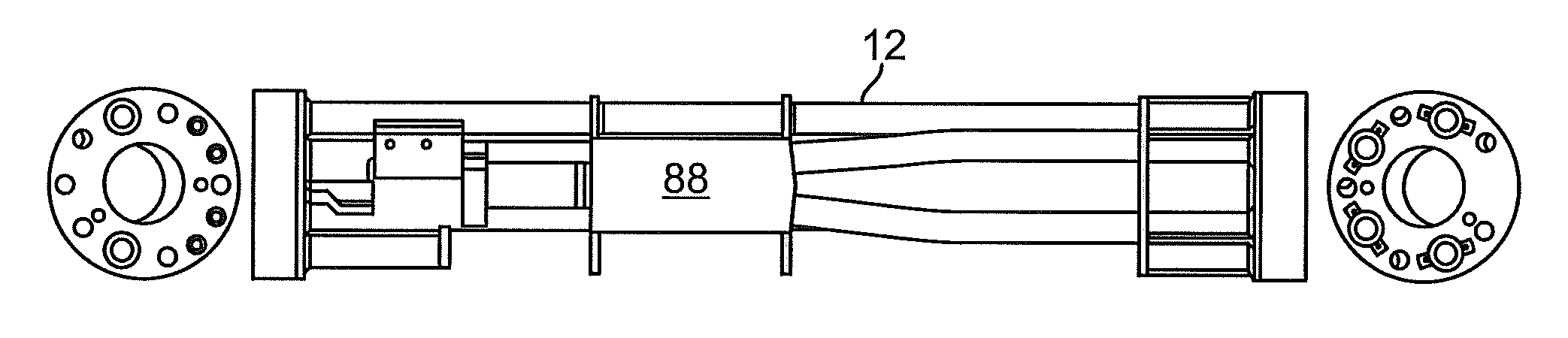

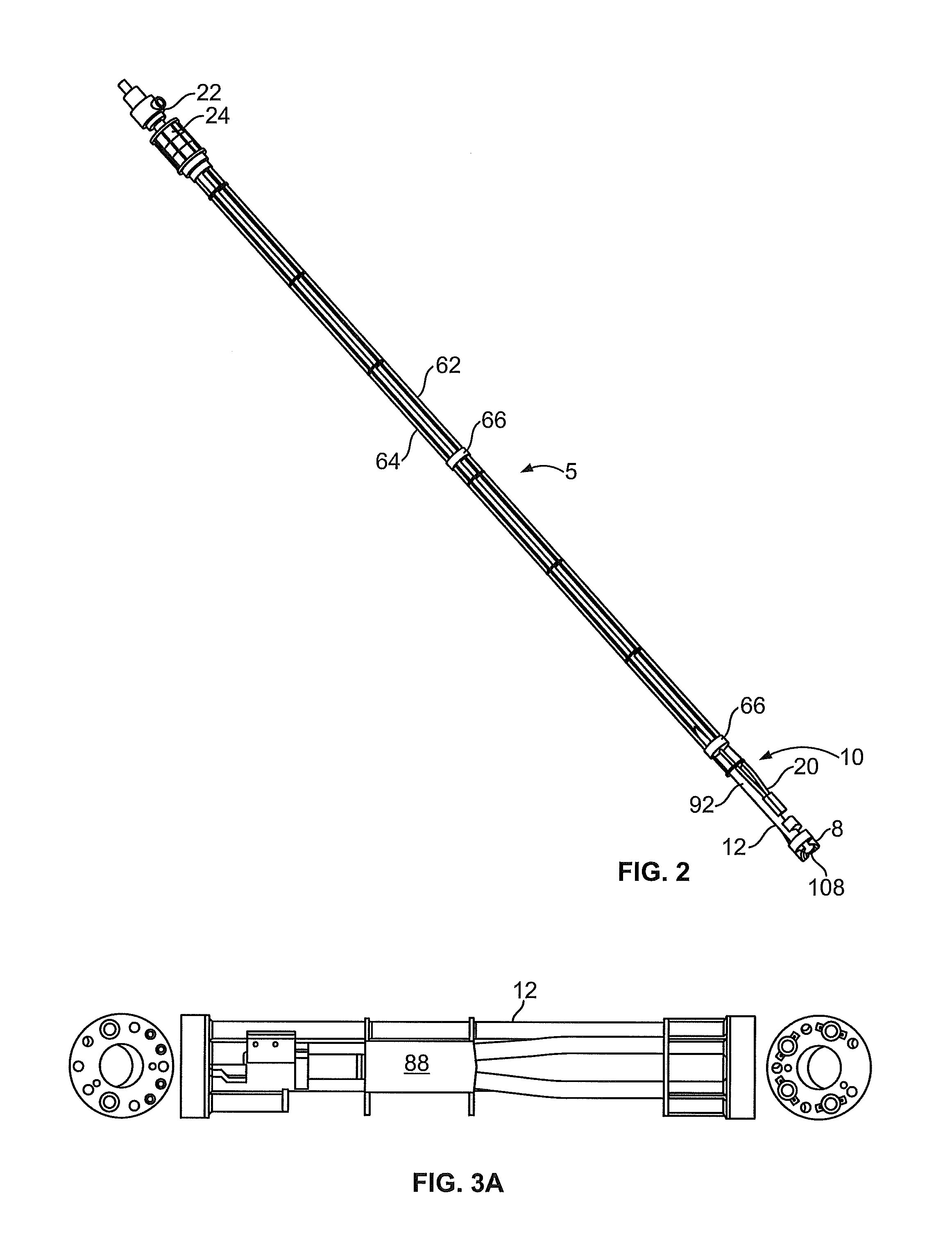

[0044]Referring now to FIGS. 2 and 6(a)-(b), a mining string 5 is illustrated in greater detail. The mining string is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com