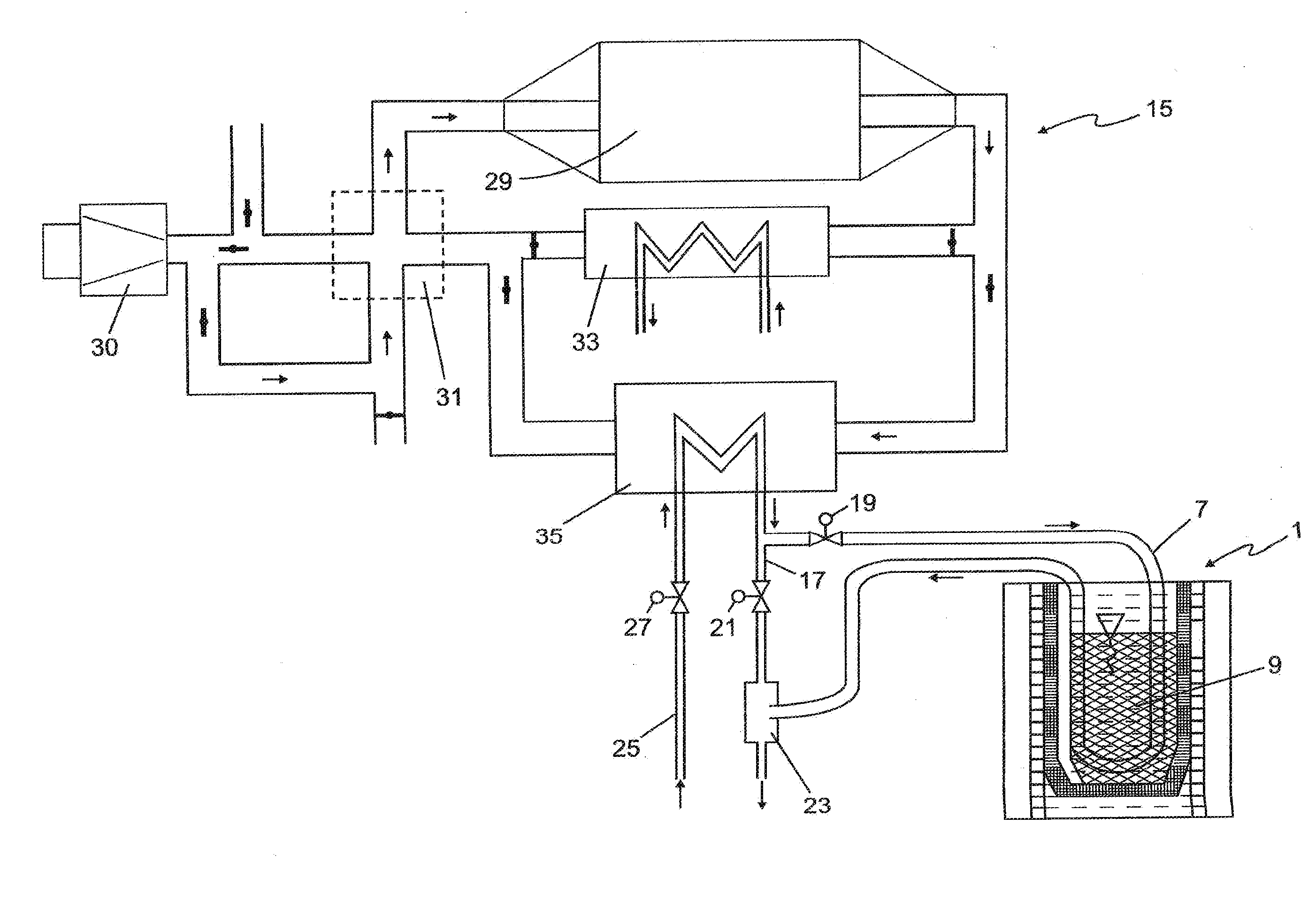

High-temperature thermal storage device with induction heating and molten metal, and thermal storage-composite system

a thermal storage device and induction heating technology, applied in the direction of heat storage devices, indirect heat exchangers, lighting and heating apparatus, etc., can solve the problem of no longer attained temperature level, at which the storage device was charged, and loss of exergy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

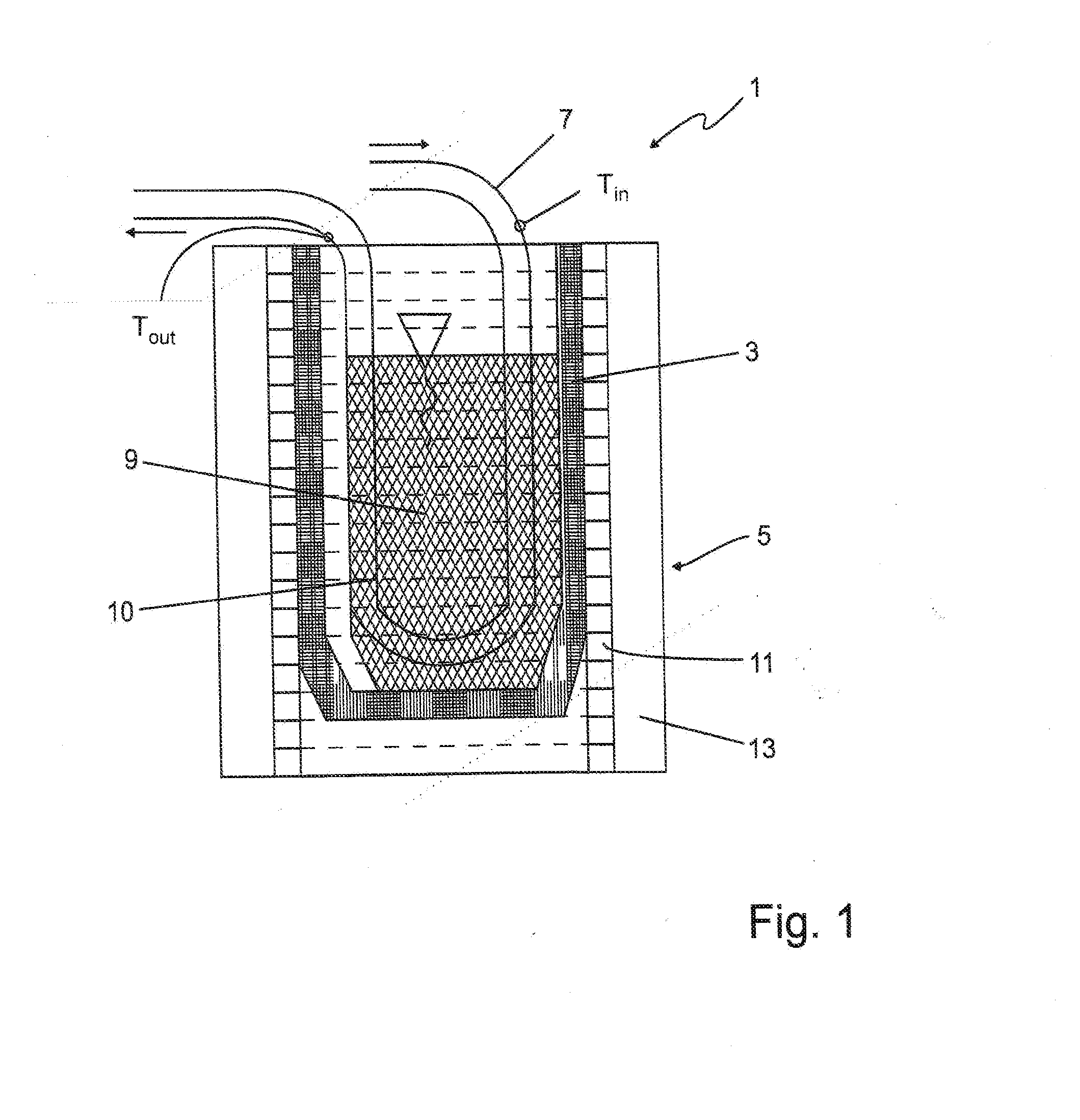

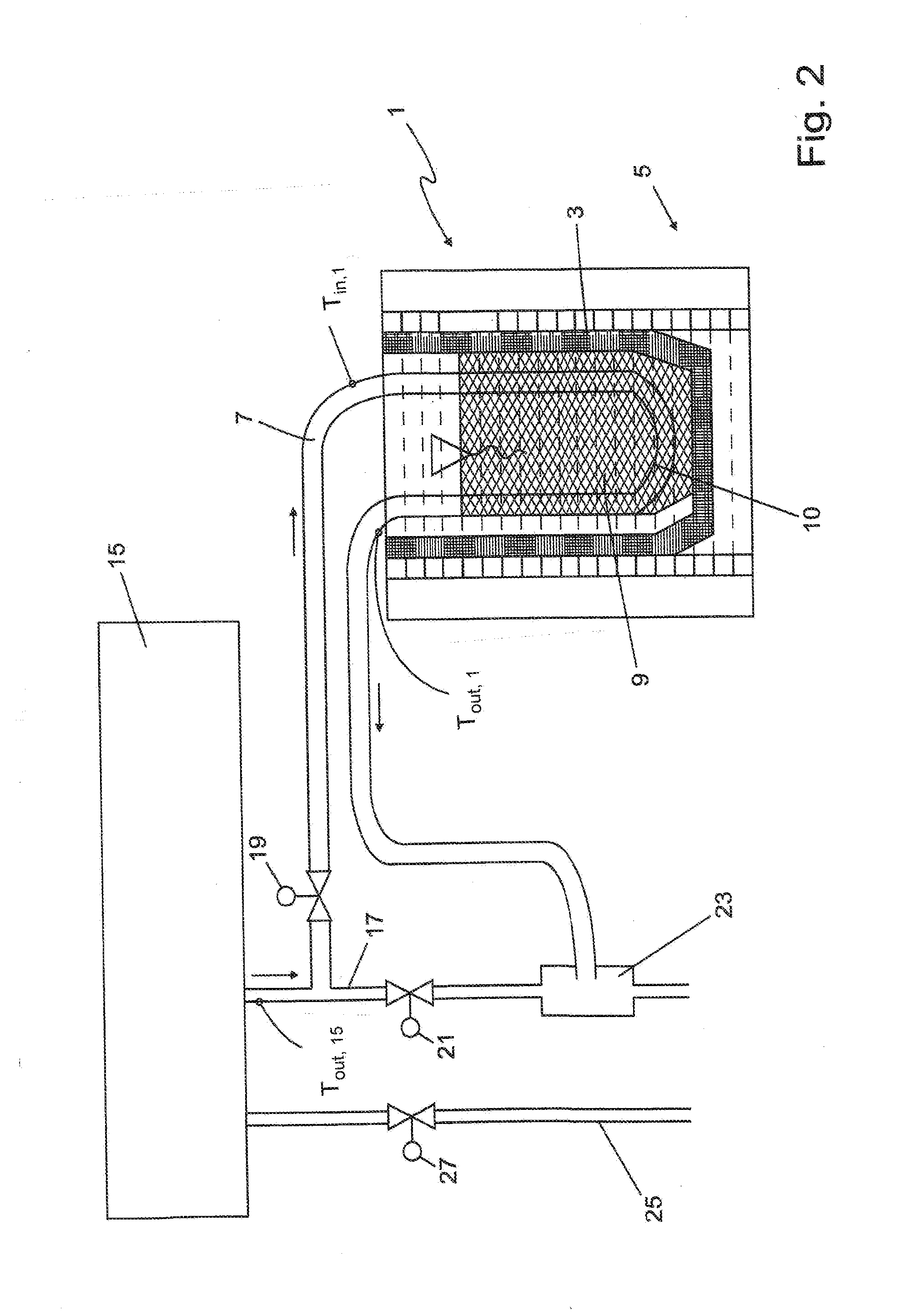

[0057]FIG. 1 shows a working example of a high-temperature thermal storage device 1 according to the invention in a highly simplified and schematic section view. The essential components of the high-temperature thermal storage device 1 according to the invention are a crucible 3, an induction heating device 5, a tubular duct 7 as well as molten metal 9 inside the crucible 3. The crucible 3 is a receptacle which is heat-resistant, even if the molten metal 9 is liquid, and, for example, has temperatures exceeding 700° C. In order to minimize heat loss, the crucible 3 includes a lid (without reference number) at its upper end.

[0058]The sidewalls of the crucible 3 are surrounded by the induction heating device 5. Such induction heating devices 5 are often used in induction furnaces and consist substantially of one or a plurality of coils 11 as well as sheet metal jacketing 13.

[0059]Since such crucibles 3 and induction heating devices 5 are known from induction furnaces for foundries, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com