Apparatus and method to feed and preheat a metal charge to a melting furnace

a technology of metal charge and apparatus, which is applied in the direction of preheating charge, blast furnace components, waste heat treatment, etc., can solve the problems of metal charge explosion risk, compromising process functionality, and compromising the integrity of the plant, so as to improve the heat yield, prevent the risk of explosion, and increase the safety of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

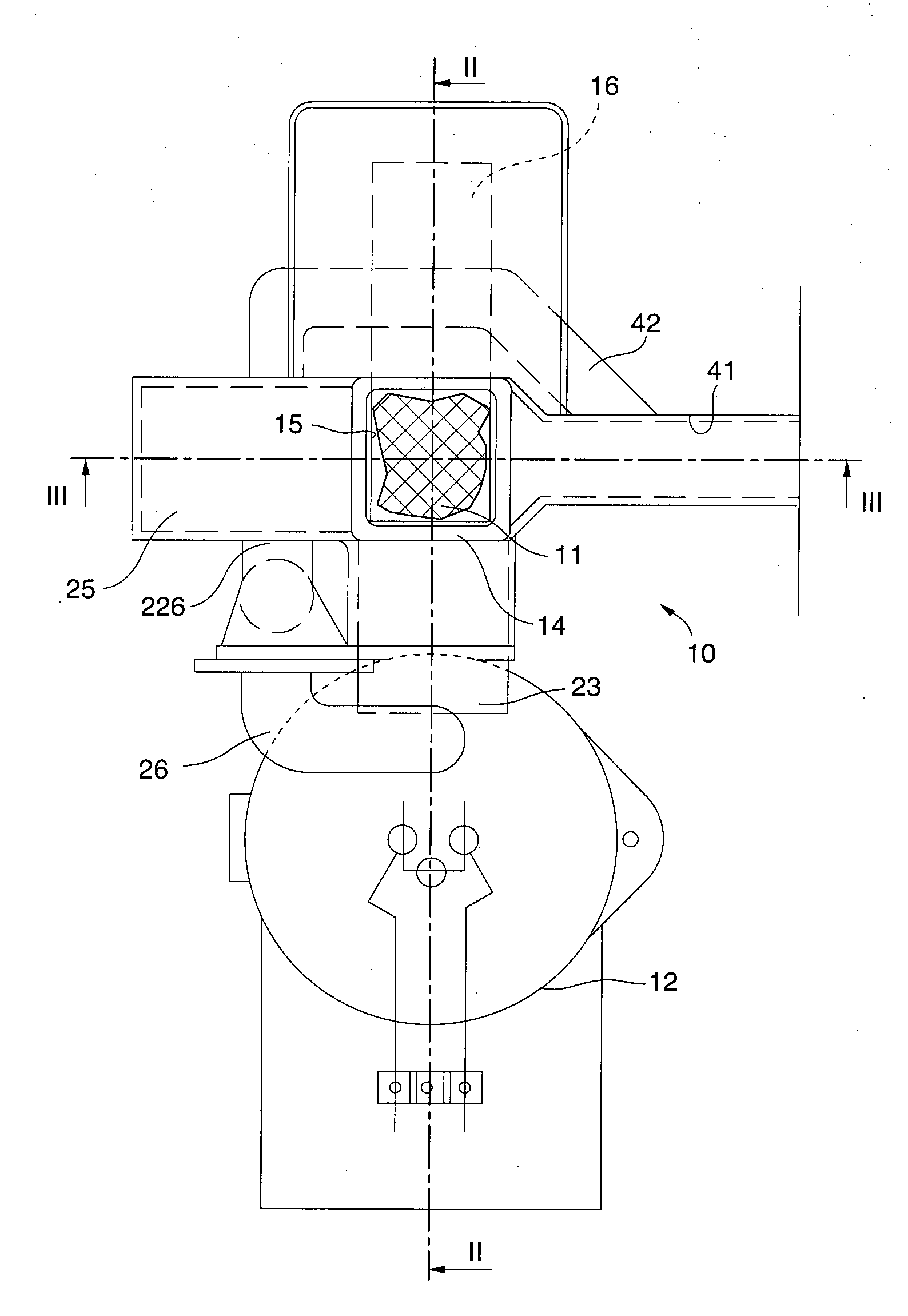

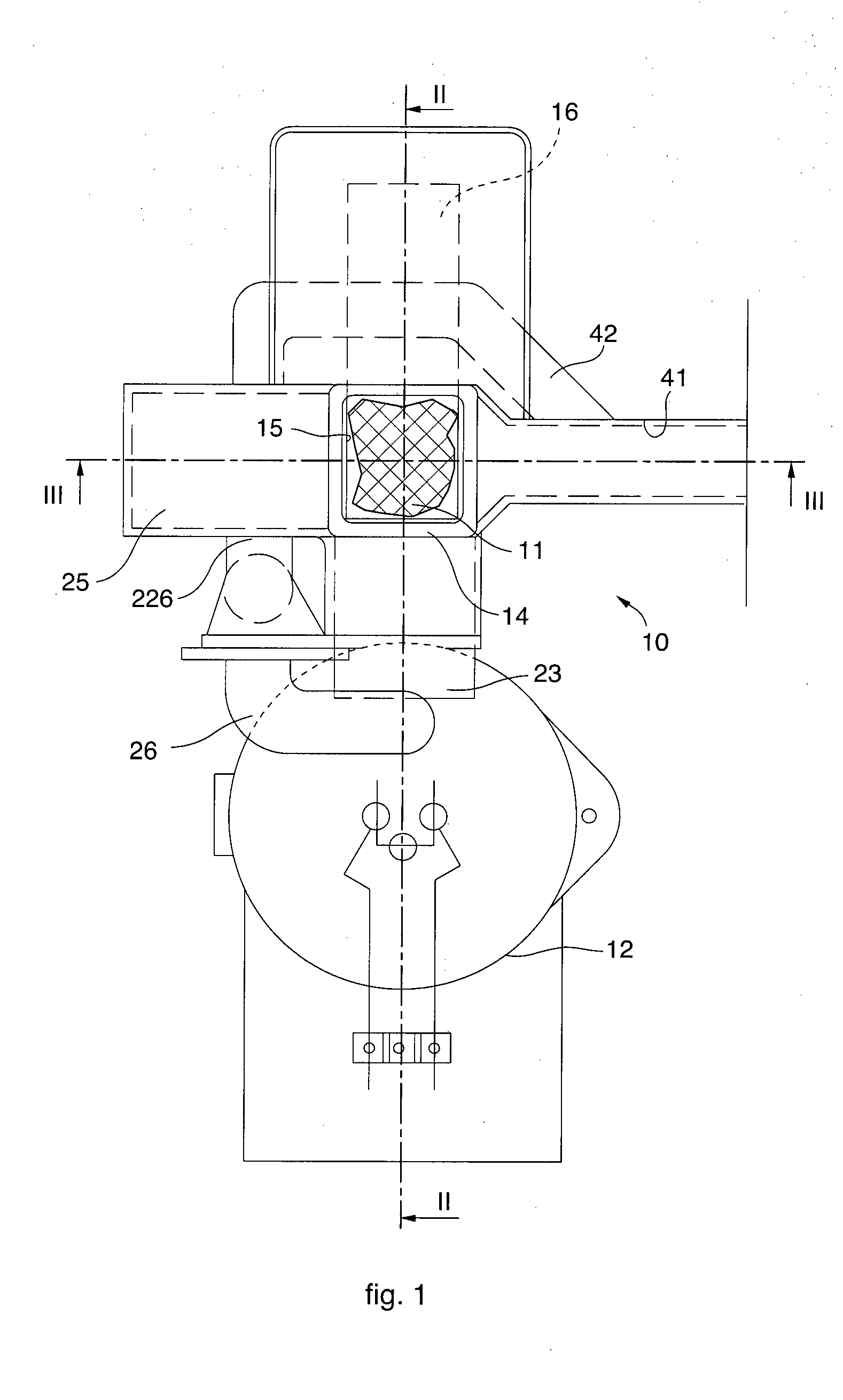

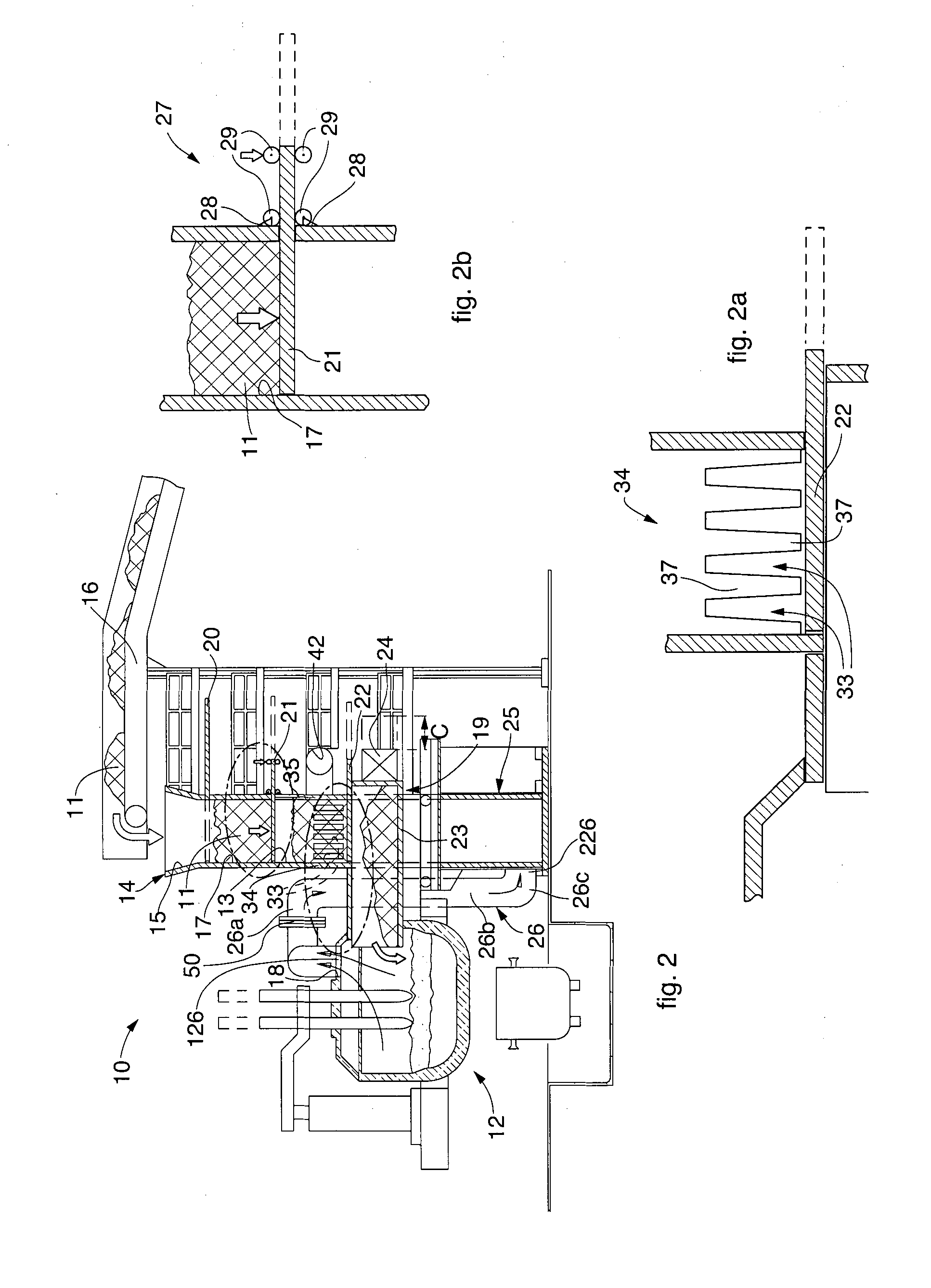

[0044]With reference to FIGS. 1, 2 and 3, an apparatus 10 according to the present invention is used to feed and pre-heat a metal charge 11, or scrap, to a melting furnace 12 of a steelworks, for example having a capacity of 100-120 t / hr.

[0045]The apparatus 10 comprises a tower 14 to feed and pre-heat the metal charge 11, with a vertical development, which is disposed at the side of and separate and autonomous from the melting furnace 12. In this way the vibrations and / or knocks originating from the tower 14 are discharged onto its own support plane 30 and onto the foundations, and not onto the melting furnace 12.

[0046]Furthermore, the apparatus 10 comprises fume conveying means to convey the fumes exiting from the melting furnace 12 to direct them toward a compartment 13 in order to pre-heat the metal charge 11.

[0047]In this case, the conveying means comprise a first pipe 26 to transport the fumes, which comprises a first end 126 connected to an exit hole 18 of the melting furnace ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| residence time | aaaaa | aaaaa |

| residence time | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com