Heat reclamation and air circulation device

a technology of air circulation device and heat reclamation, which is applied in the direction of ventilation system, heating type, lighting and heating apparatus, etc., can solve the problems of reducing overall heating requirements, reducing heat loss, and increasing heat loss, so as to reduce heat loss and improve power without significant increase in noise. , the effect of small siz

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

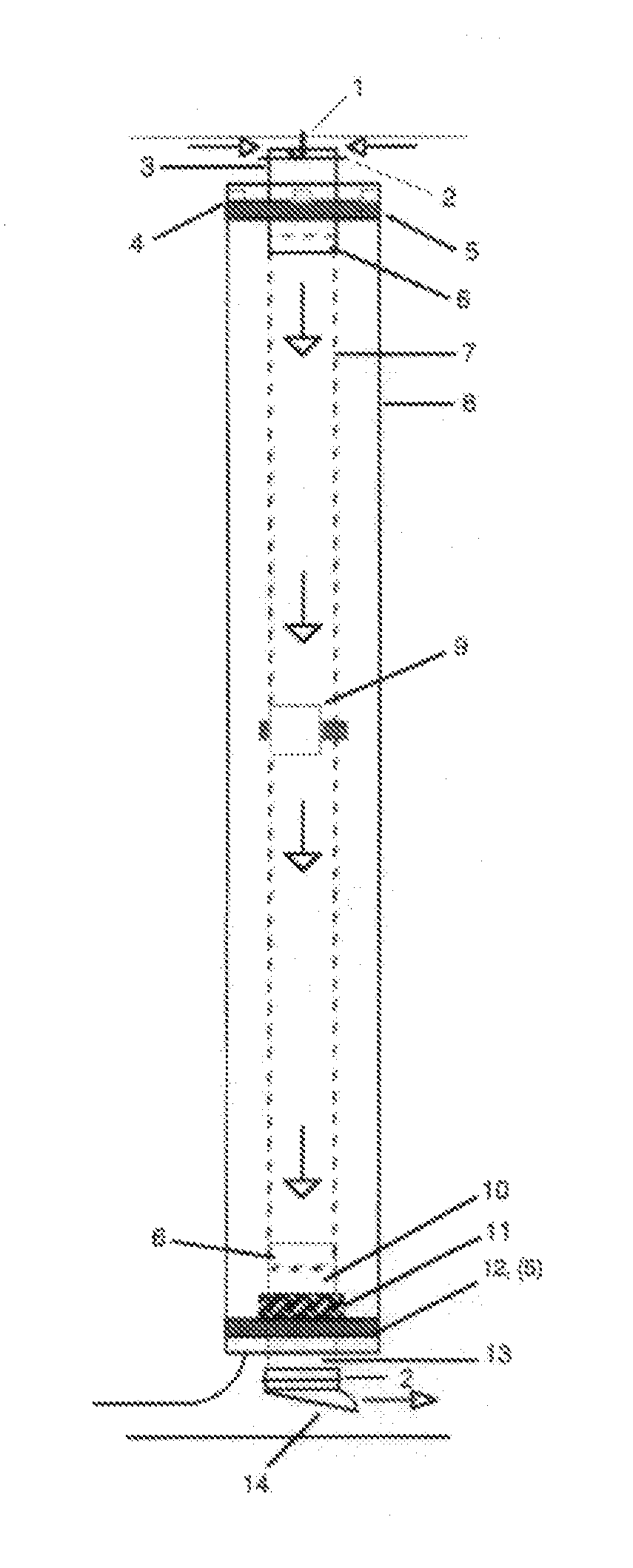

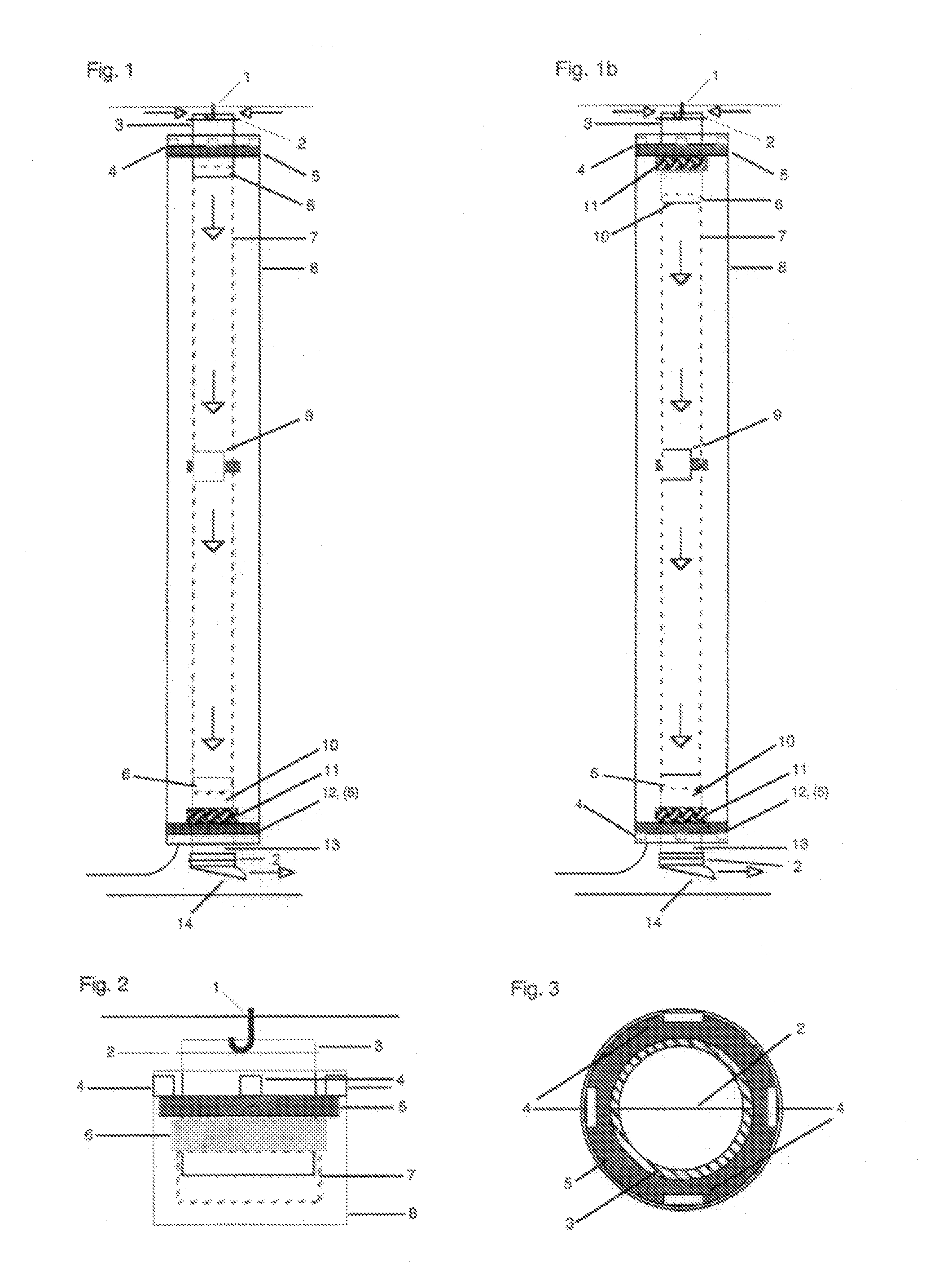

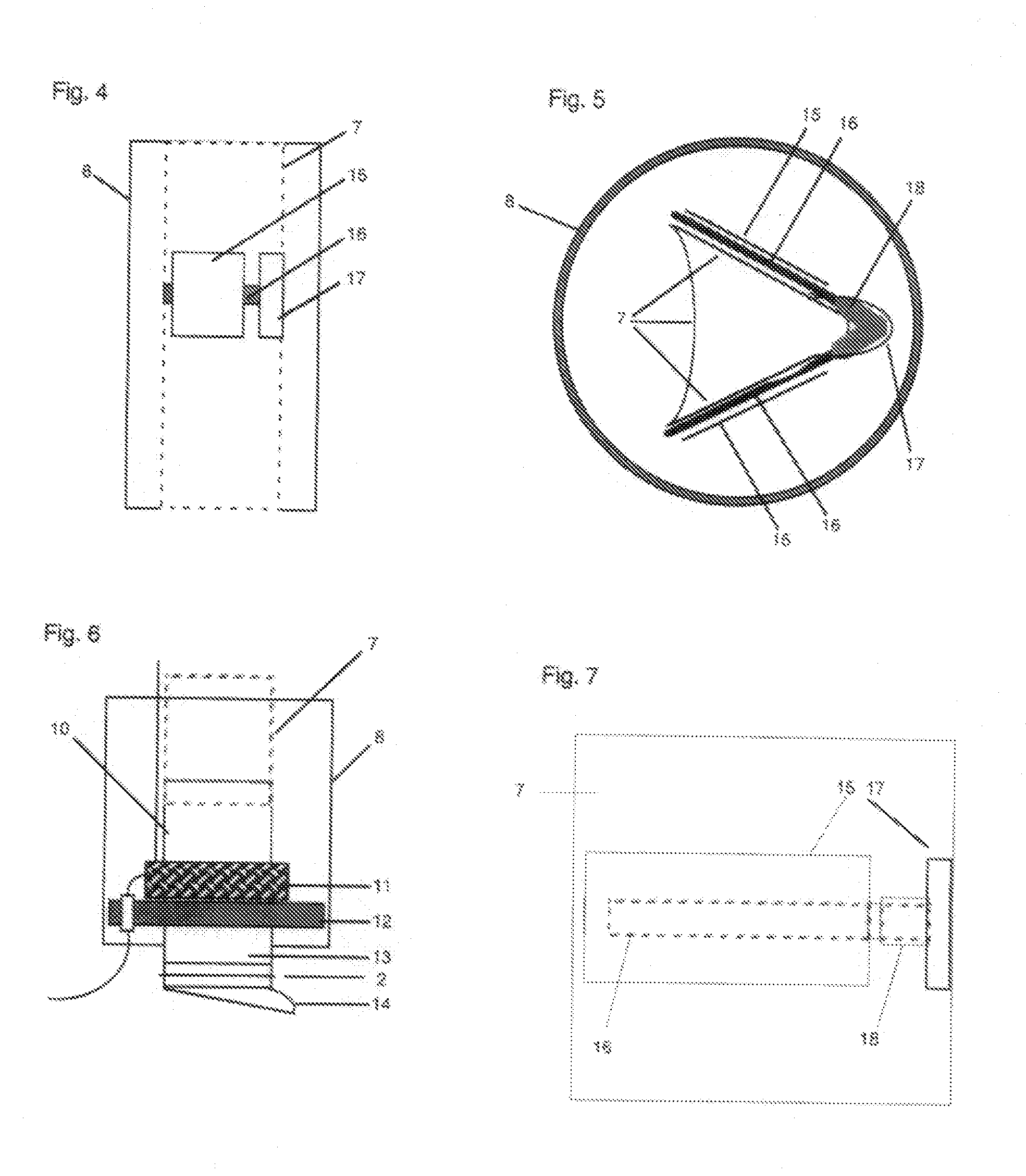

[0022]Referencing the accompanying drawings, in FIG. 1 a heat reclamation and recirculation device of the present invention is shown suspended by a small hook 1 screwed into the ceiling of a room. By using lightweight materials throughout the design, it is intended that the device will be suspended from any common ceiling material such as drywall, without requiring an anchor device beyond a small screw-in cup hook, and powered from below by a cord extending from the bottom of the device to a nearby wall outlet. For cooling, and powering the fan when the tube is rotated 180 degrees in the vertical plane, a parallel set of small power wires is affixed to the wall of the inner tube and ending in a power plug, in order to maintain a power connection at the bottom of the tube when placed in the new orientation. As the device has extremely modest electrical requirements, it is envisioned that a power source may ultimately be rechargeable batteries, or solar cells incorporated into the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com