Expandable Boundary Layer Turbine

a technology of boundary layer turbines and turbine blades, which is applied in the direction of machines/engines, manufacturing tools, mechanical equipment, etc., can solve the problems of increasing maintenance costs and dependability, not gaining widespread application, and the blades of conventional turbines are expensive to construct, so as to reduce the risk of distortion and breakage, improve the support of the disk, and minimize the disturbance of the natural flow of fluids.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

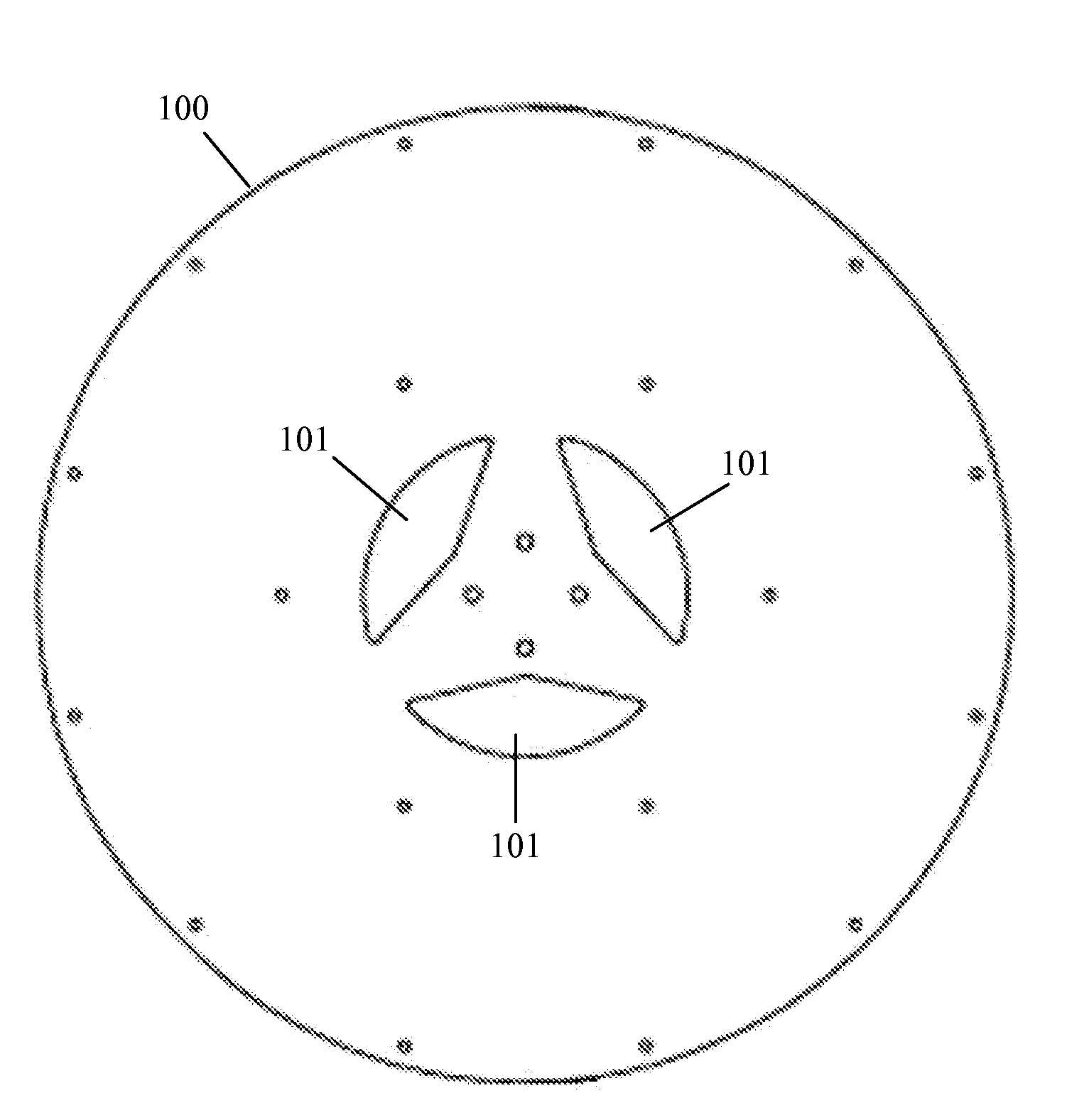

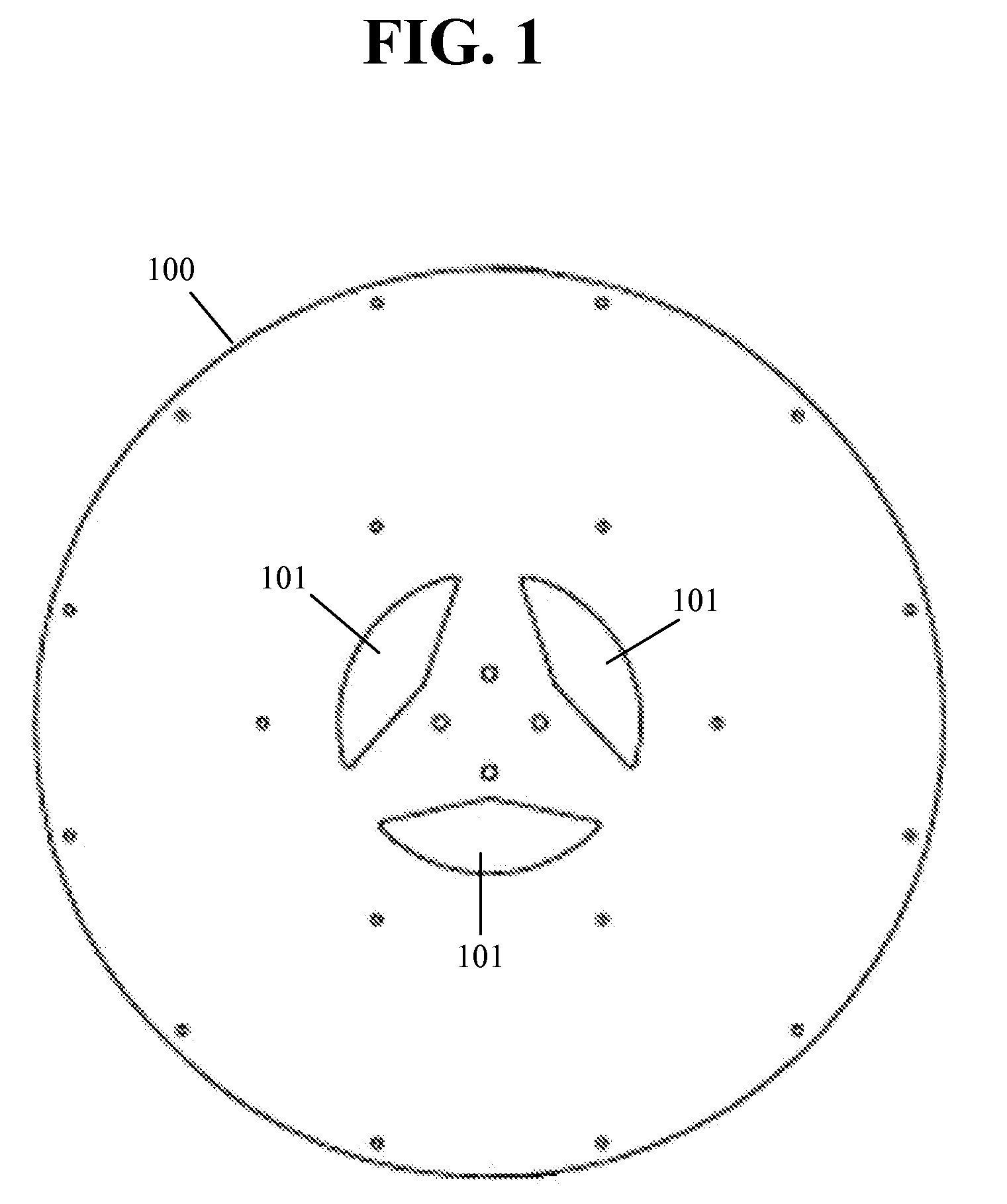

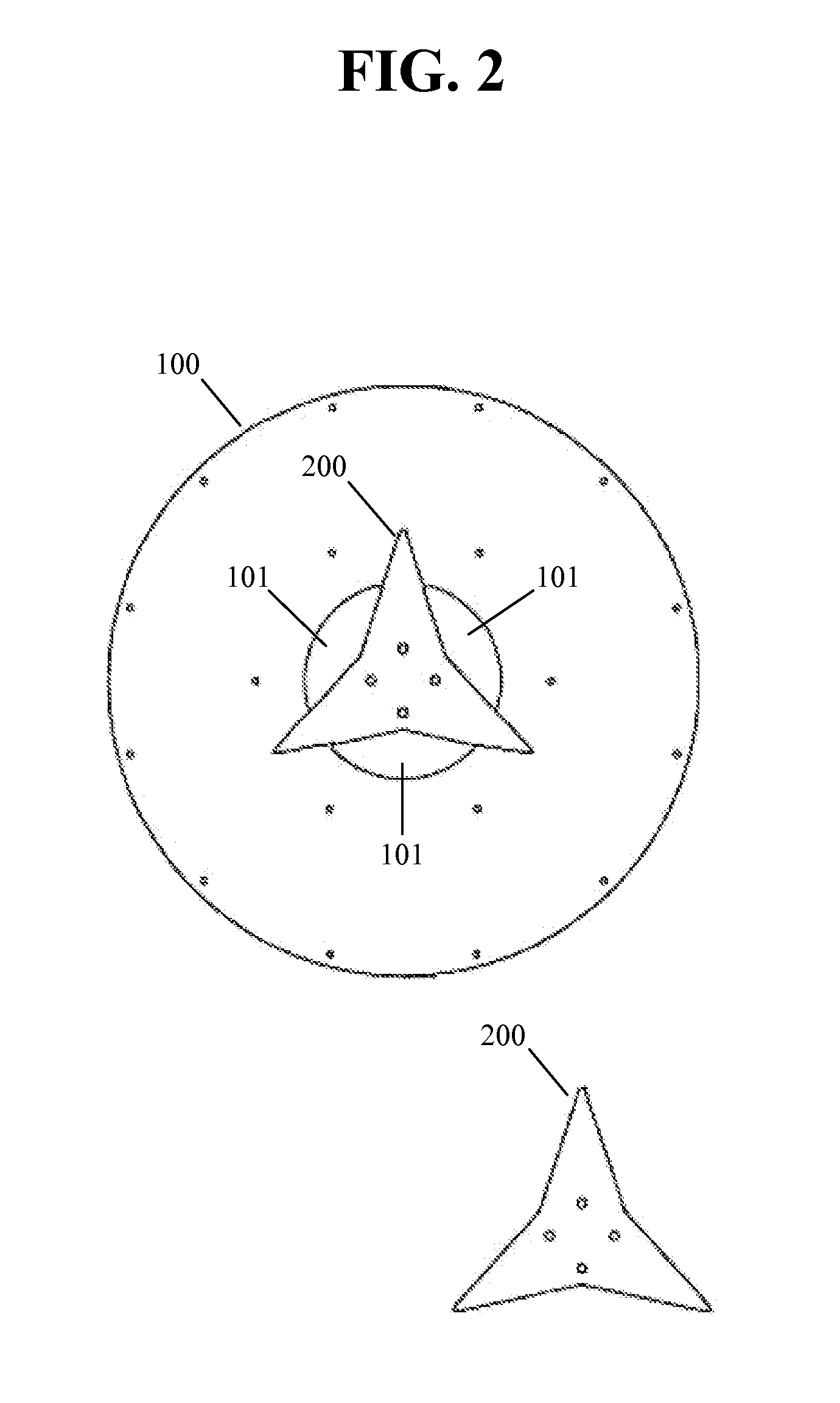

[0024]The present invention pertains to a low-cost boundary layer turbine comprising a bolt-on hub and directed-flow tuned inlet nozzle design that significantly decreases breakage and distortion and increases the efficiency of the system. The following description contains specific information pertaining to various embodiments and implementations of the invention. Furthermore, the present specification need not represent some of the specific details of the present invention in order to not obscure the invention. A person of ordinary skill in the art would have knowledge of such specific details not described in the present specification. Others may omit or only partially implement some features of the present invention and remain well within the scope and spirit of the present invention.

[0025]The following drawings and their accompanying detailed description apply as merely exemplary and not restrictive embodiments of the invention. To maintain brevity, the present specification ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cohesion | aaaaa | aaaaa |

| durability | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com