Apparatus for producing pitch-based chopped carbon fiber and producing method of the chopped fiber

a technology of carbon fiber and apparatus, which is applied in the direction of manufacturing tools, melt spinning methods, applications, etc., can solve the problems of low strength and easy breakage, difficult to produce carbon fiber in continuous way, and carbon fiber produced by the prior art, etc., to maximize the mechanical strength of a pitch precursor, high cost, and excellent strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

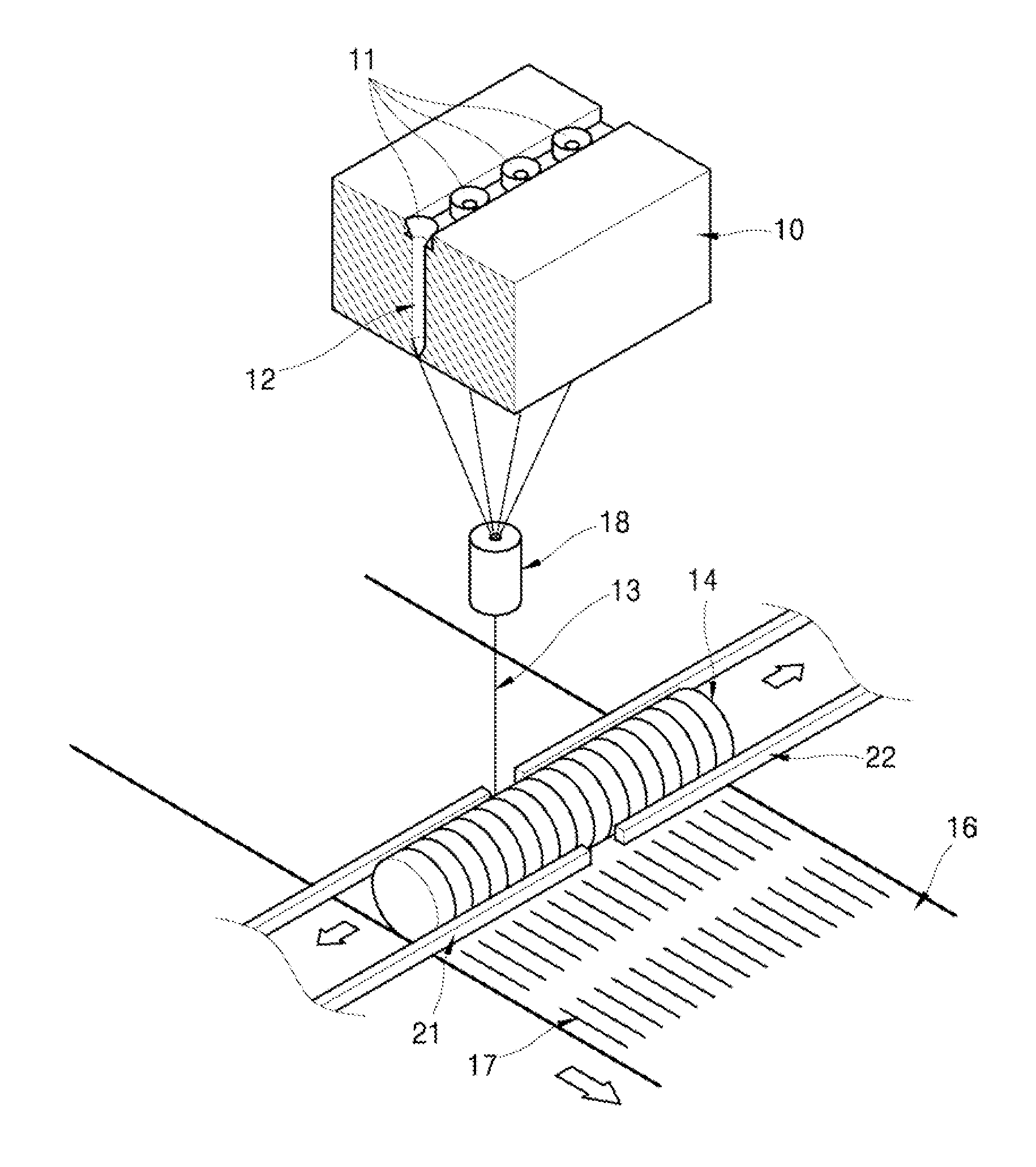

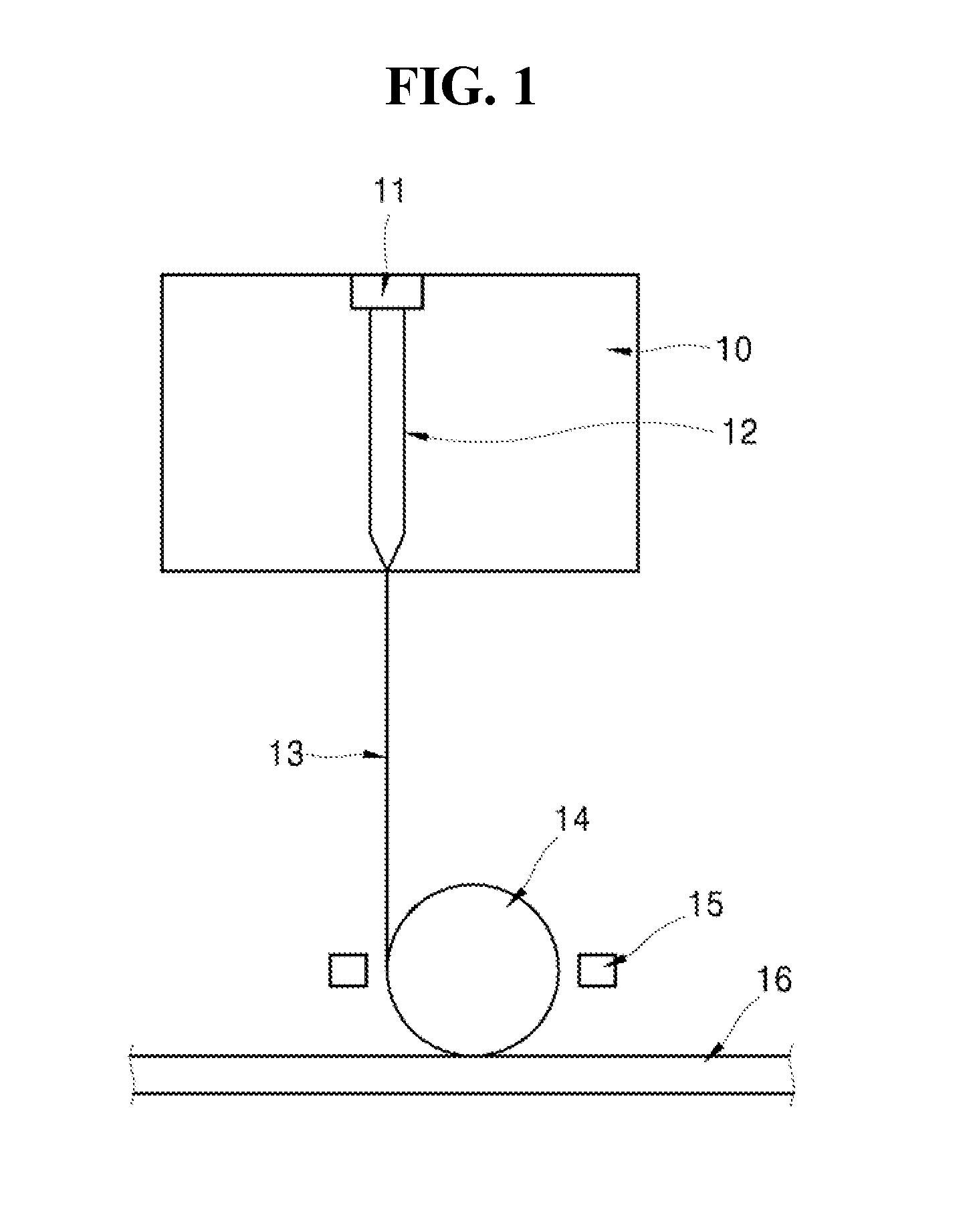

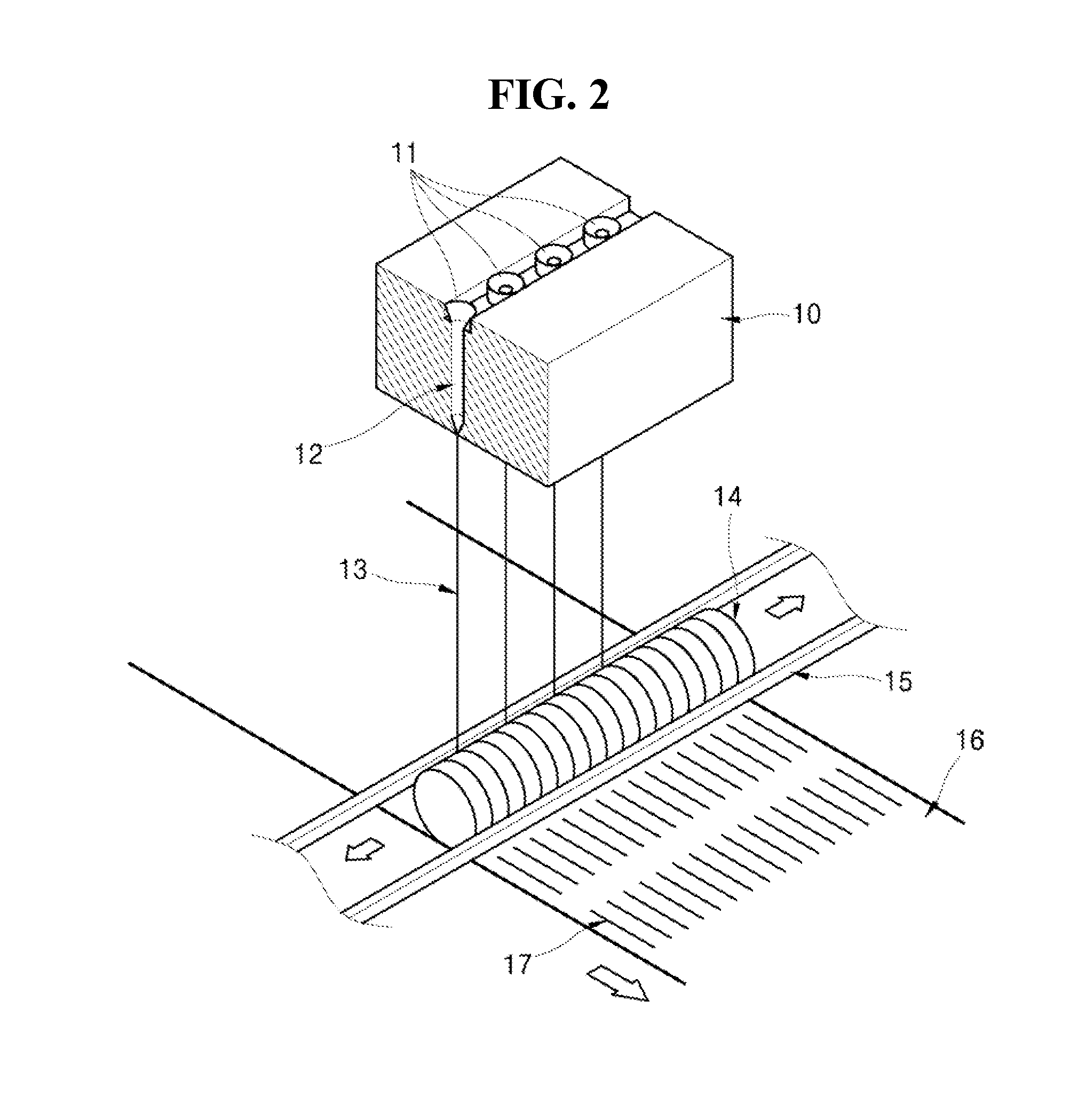

[0088]100 wt % isotropic pitch with a softening point of 280° C. was melt-spun and wound with 500 m / min to produce a pitch fiber. The pitch fiber which was spun (melt spun) while wound on the rotation roll was cut in a constant length of 3 cm. The cut fiber (chopped fiber) was heated to a temperature of 260° C. for 1 hour to perform a first non-embodiment process, and then, the chopped fiber, which had undergone the first infusibilized, was processed in a second infusibilization process in a infusibilizing oven at a speed of 1° C. / min within a infusibilization temperature of 280-320° C. The chopped fiber, which had undergone the second infusibilization process, was carbonized at a heating rate of 10˜20° C. / min for 10 minutes at 1000° C. and finally transformed into a chopped carbon fiber. An average fiber length of the produced carbon fiber was 3 cm, an average diameter was 8 μm, and tensile strength was 1.5 GPa.

embodiment 2

[0089]All conditions are the same Embodiment 1 except that the speed of the rotation roll is 500 m / min. An average fiber length of the produced carbon fiber was 3 cm, an average diameter was 10 μm, and tensile strength was 1.2 GPa.

embodiment 3

[0090]All conditions are the same Embodiment 1 except that the speed of the rotation roll is 500 m / min. An average fiber length of the produced carbon fiber was 6 cm, an average diameter was 10 μm, and tensile strength was 1.2 GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com