Polymeric monolithic capacitor

a polymer monolithic capacitor and polymer technology, applied in the direction of wound capacitors, fixed capacitor details, fixed capacitors, etc., can solve the problems of limited degree to which the thickness of the pp film can be reduced, mfc capacitors, and film thickness must be adequate, so as to minimize the electrical resistivity of the capacitor termination, the effect of maximizing mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

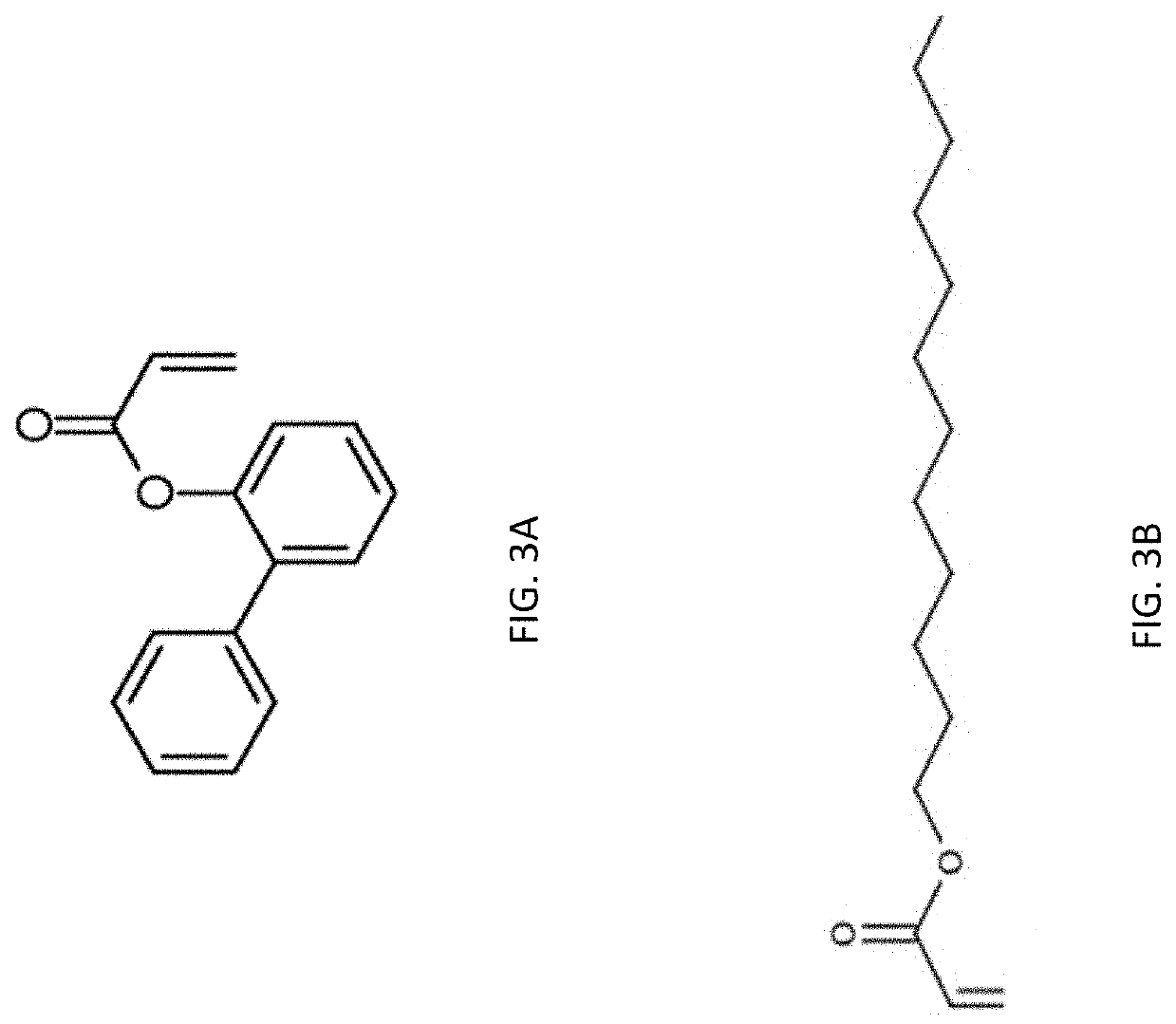

[0024]This invention is directed at fabrication of a polymeric monolithic capacitor possessing self-healing properties that prevent catastrophic failure of the capacitor (and that may result, instead, only in a benign failure mode), high temperature stability, resistance to degradation in high-temperature and high-humidity environments, and ability to handle high-ripple currents, and extreme thermomechanical environments.

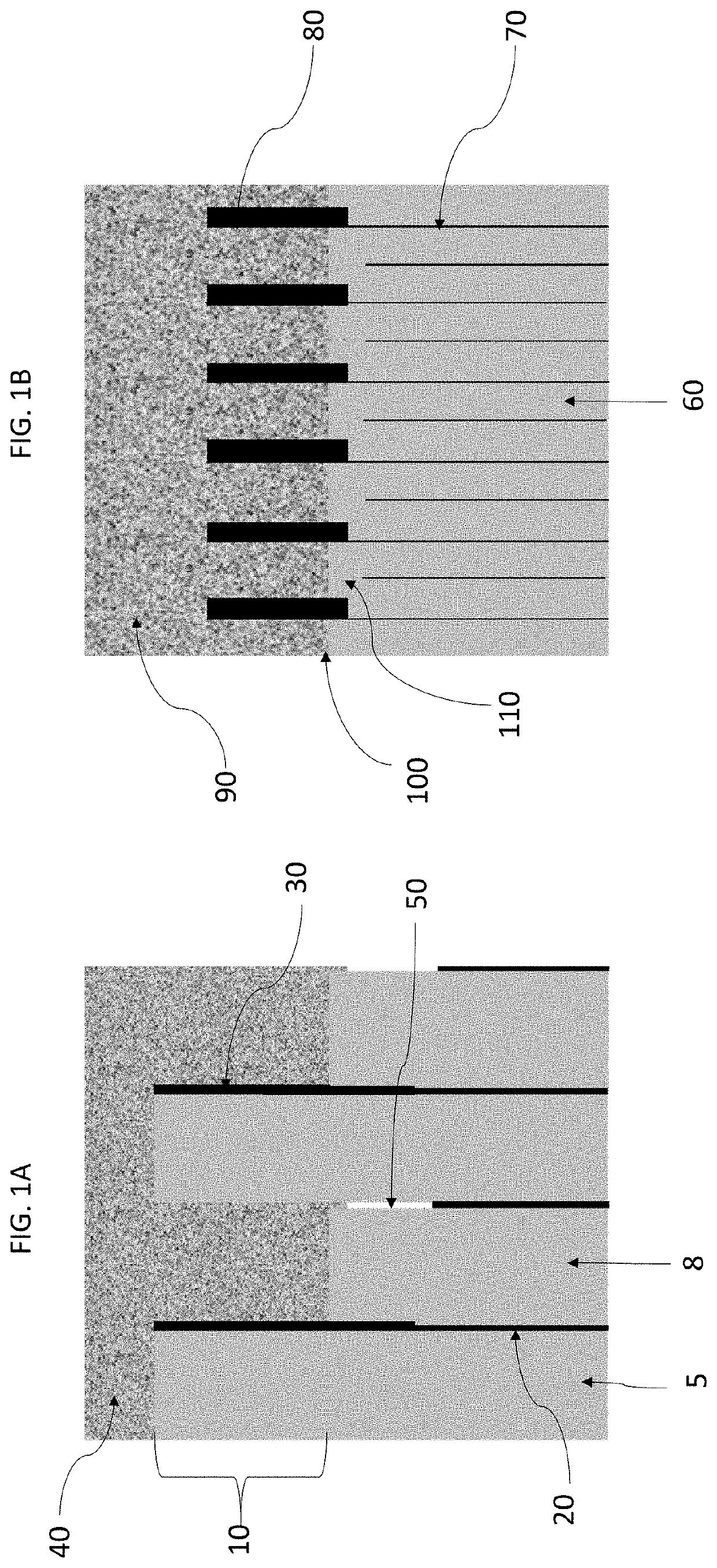

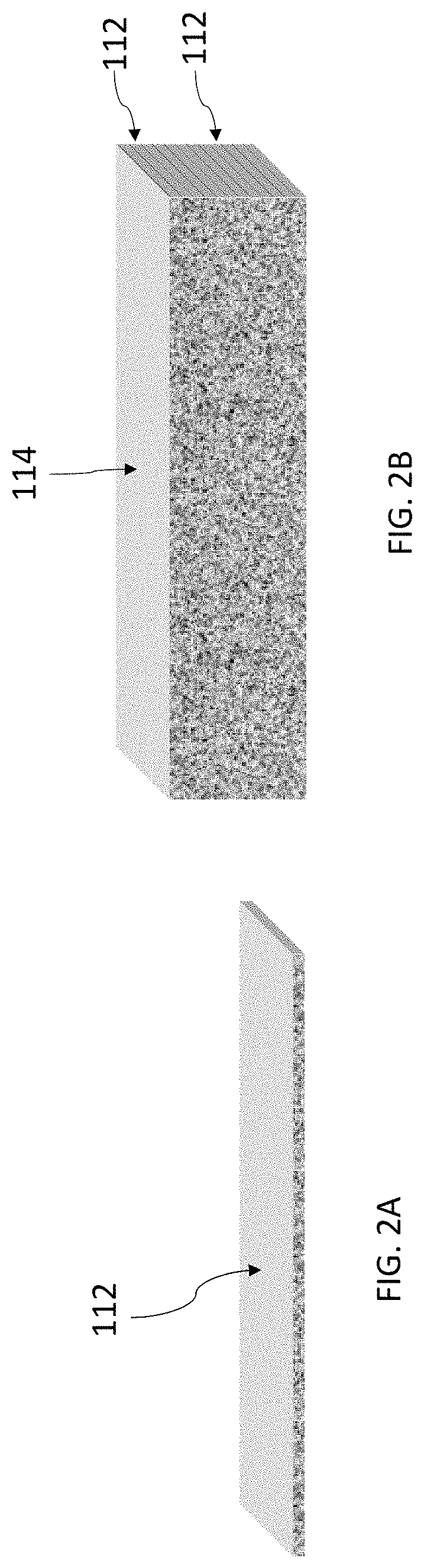

[0025]The term “polymer monolithic capacitor” (PMC) is used to describe a capacitor that originates as a multilayer composite (or “mother capacitor”) material produced or formed around a rotating drum in the form of thousands of polymer dielectric and electrode layers. The mother capacitor material is removed from the drum and is processed into individual capacitors, via a series of process steps that include pressing the mother capacitor material, segmentation of the pressed material into individual capacitors, etching of the electrodes at the cut edges to prevent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| sheet resistance | aaaaa | aaaaa |

| sheet resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com