Combustion Apparatus of Composite Heat Carrier Generator

a technology of composite heat carrier and combustion apparatus, which is applied in the direction of steam generation using hot heat carriers, steam generation heating methods, etc., can solve the problems of polluting the environment, and removing about 10% of fuel hea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

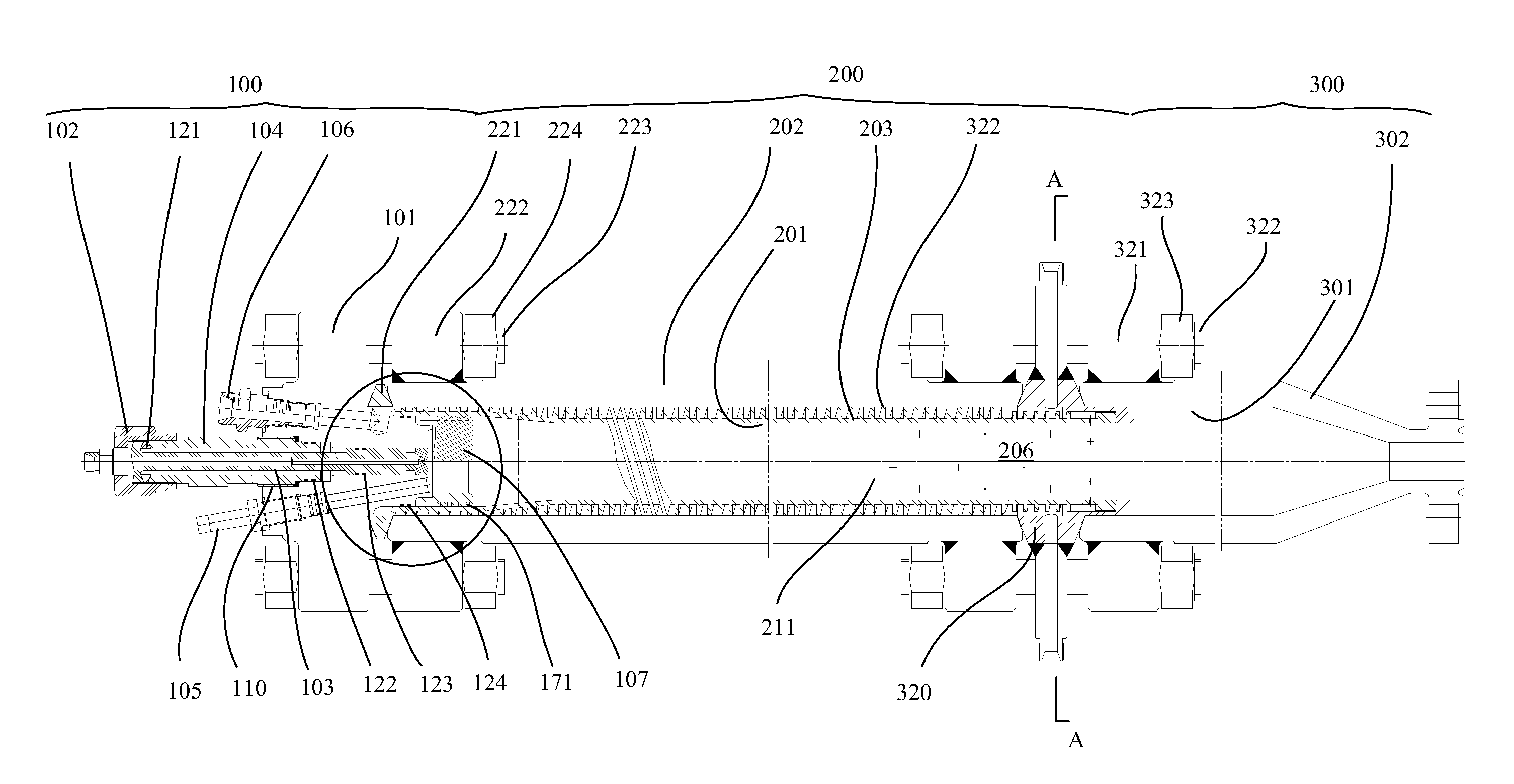

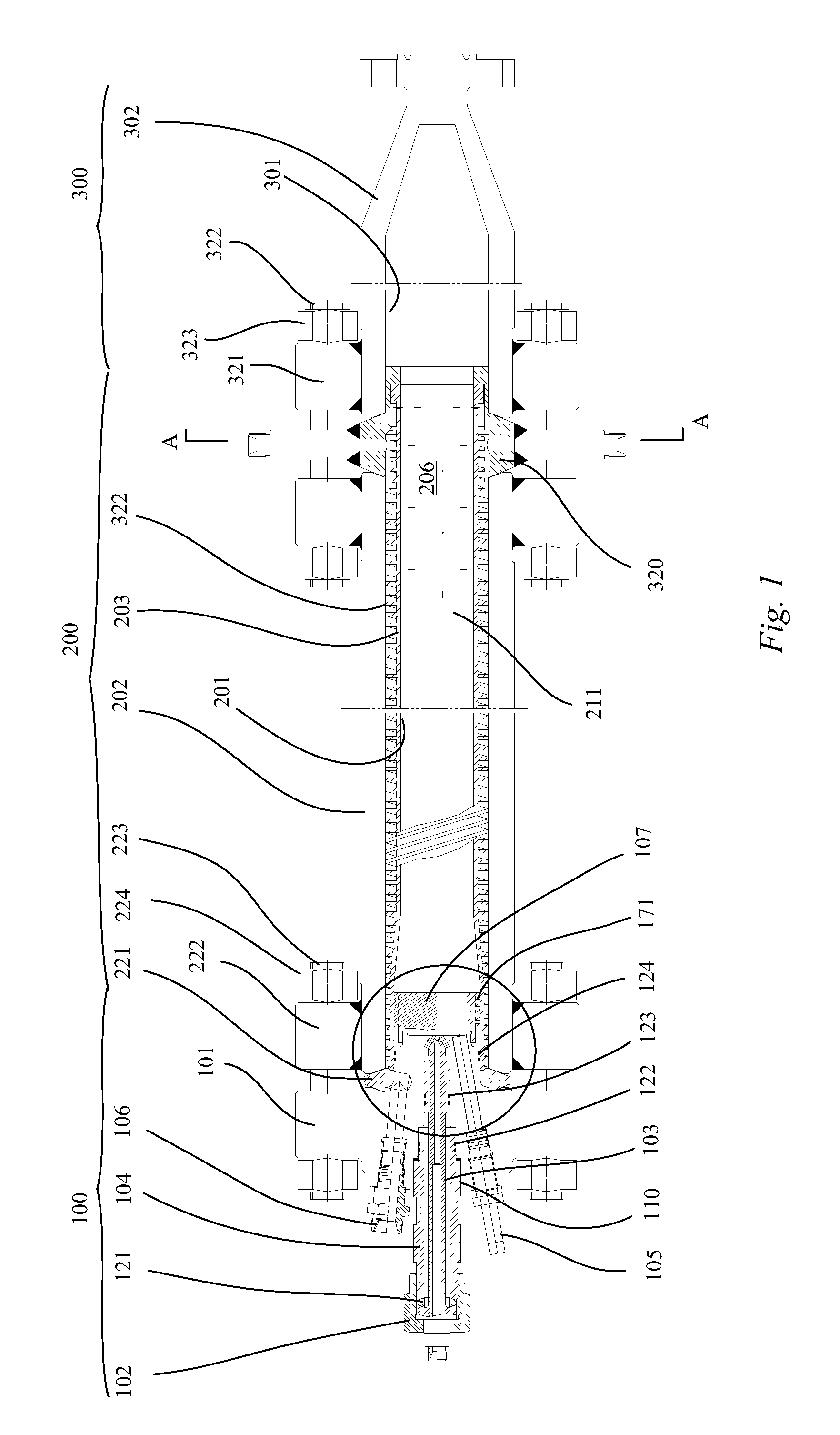

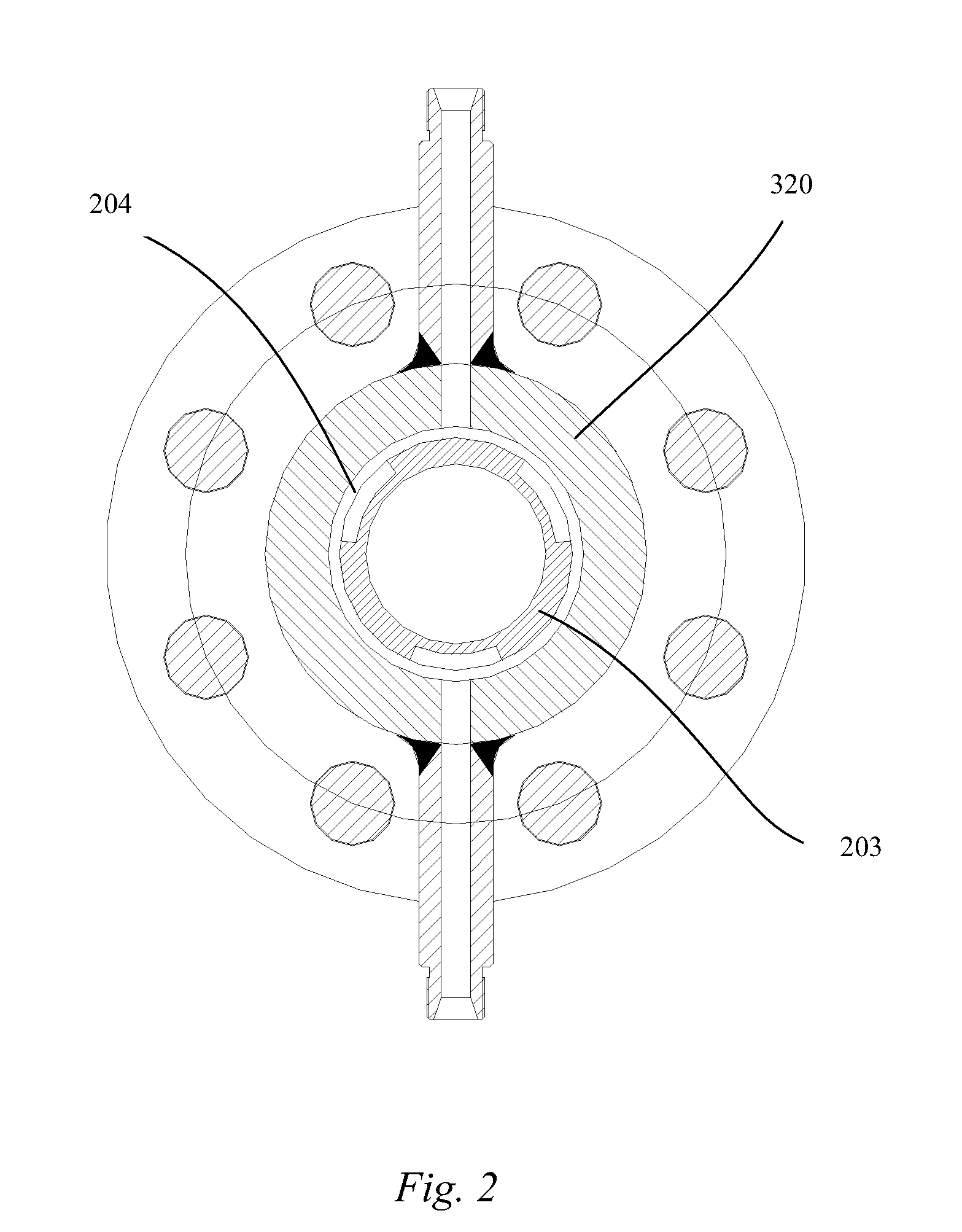

Image

Examples

second embodiment

[0039]FIGS. 9 and 10 are structural schematic diagrams of a fuel spray nozzle according to the present disclosure. The combustion apparatus of the present disclosure can not only use diesel oil as fuel, but also use crude oil as fuel. What is required is only replacing the fuel receiving nozzle and the spray nozzle. Compared with the embodiments shown in FIGS. 6-8, the fuel spray nozzle 103 of this embodiment is provided with another group of spray nozzle atomization holes 135 on the outer edge face of the fuel spray nozzle, near the edge. The spray nozzle atomization holes 135 are in communication with the fuel spray holes 133. It can be seen from FIG. 10 that a first group of spray nozzle atomization holes 132 located at the center of the outer edge face of the fuel spray nozzle 103 comprises 2 holes, and a second group of spray nozzle atomization holes 135 located at the edge of the outer edge face of the fuel spray nozzle 103 comprises 6 holes. Moreover, the diameter of the spra...

third embodiment

[0040]FIGS. 11-15 are respectively structural schematic diagrams of a fuel spray nozzle according to the present disclosure. The combustion apparatus of the present disclosure can not only use diesel oil as fuel, but also use natural gas as fuel. What is required is only replacing the fuel receiving nozzle and the fuel spray nozzle. It is to be noted that the part of the outer edge face of the fuel spray nozzle close to the edge is provided with a group of swirl holes 136. These swirl holes 136 are also in communication with the annular groove 134, and a vortex can be formed in the pre-combustion chamber when air is sprayed into the pre-combustion chamber via the swirl holes 136, so that an ignition is easier.

[0041]Compared with the prior art, the beneficial effects of the various embodiment of the present disclosure are:

[0042]1. In the present disclosure, the high-pressure air passes through the cyclone into the combustion chamber via the cyclone, which can preheat air, reduce the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com