Testing device and its calibration method

a testing device and calibration method technology, applied in measurement devices, automated test systems, instruments, etc., can solve the problems of increasing device costs, affecting reducing the calibration efficiency of the test device, so as to achieve the effect of short calibration tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0098]An embodiment of the invention will be described with reference to the accompanying drawings.

[0099][Configuration of Testing Device]

[0100]Firstly, the configuration of a testing device according to the embodiment of the invention will be described.

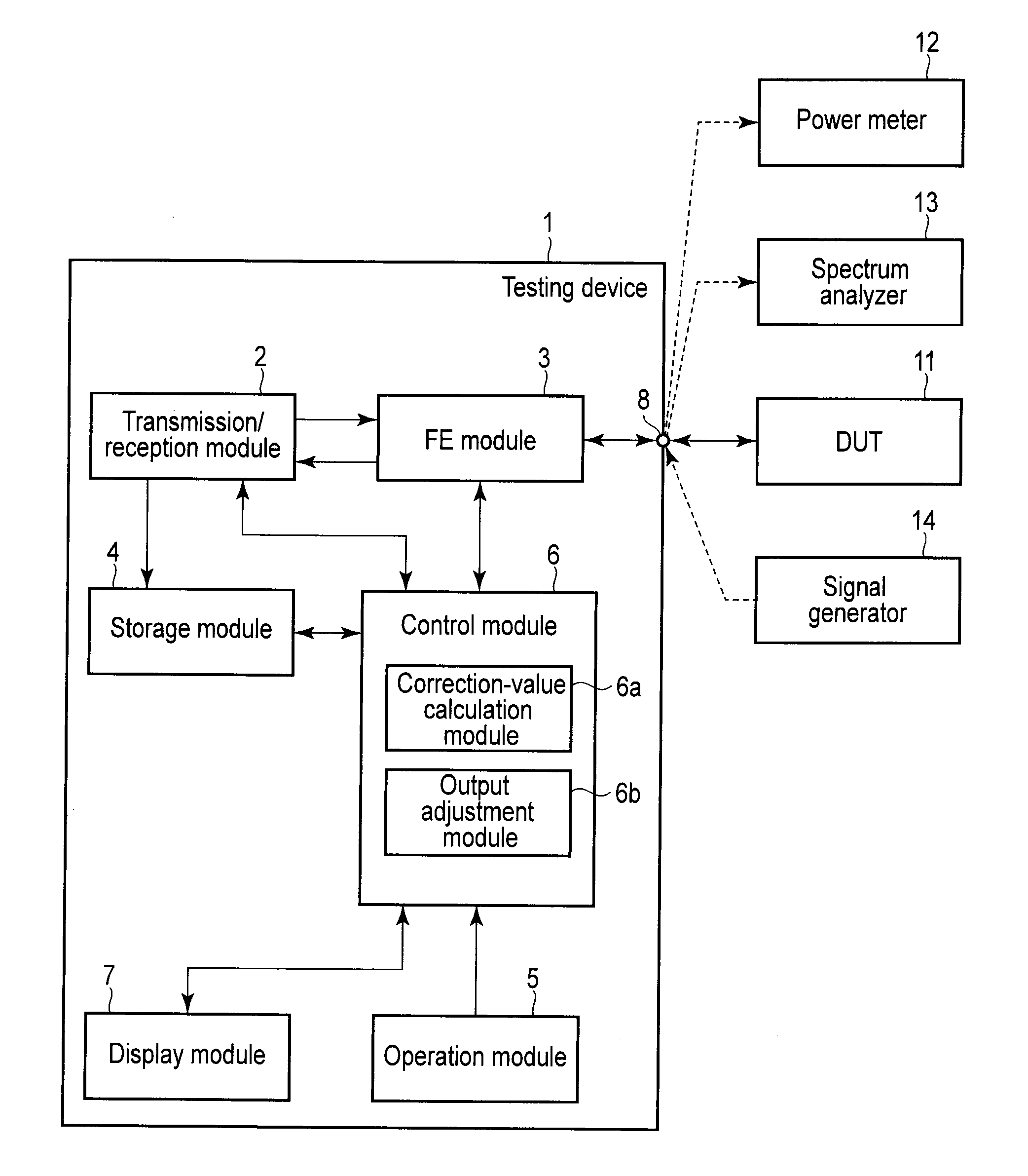

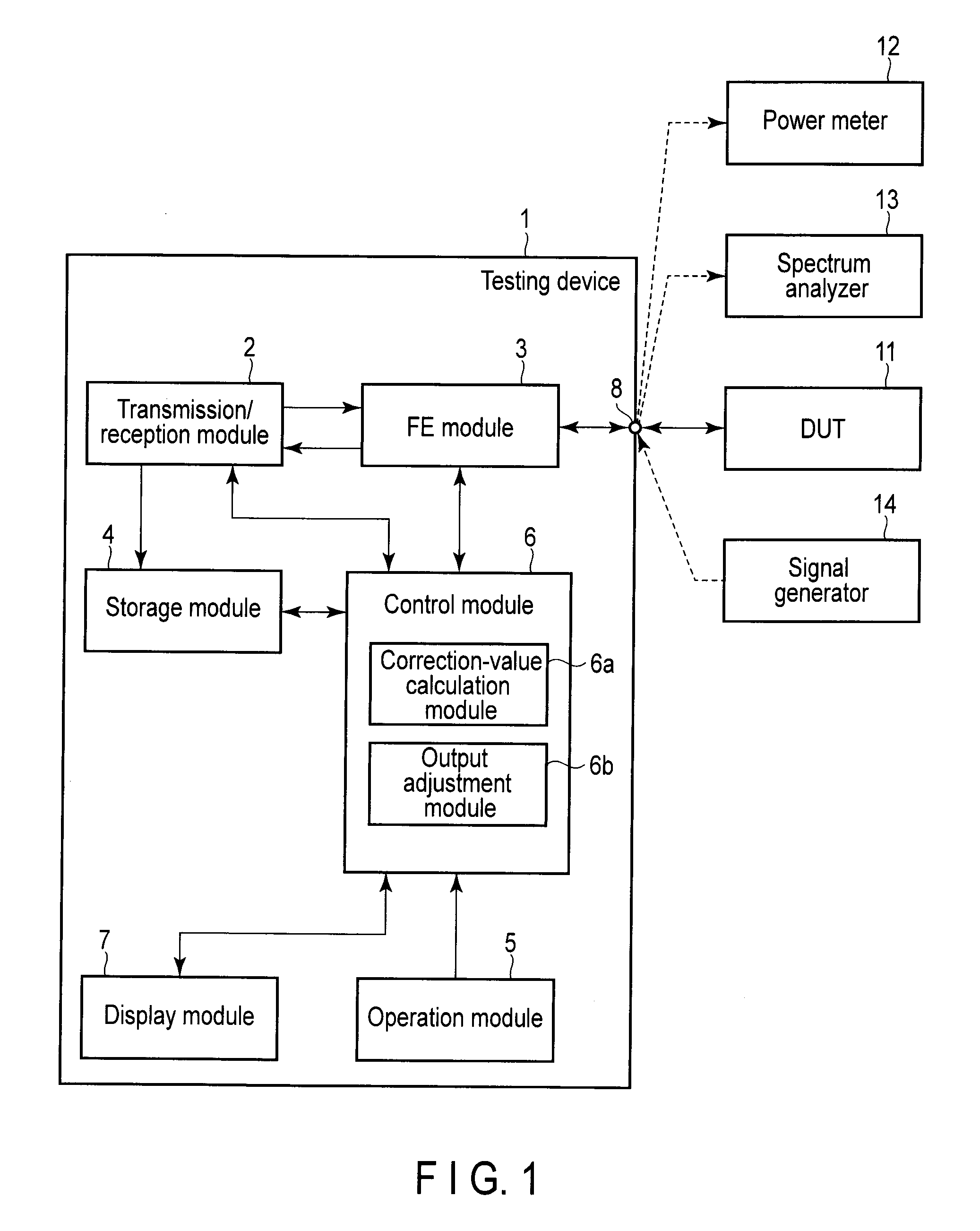

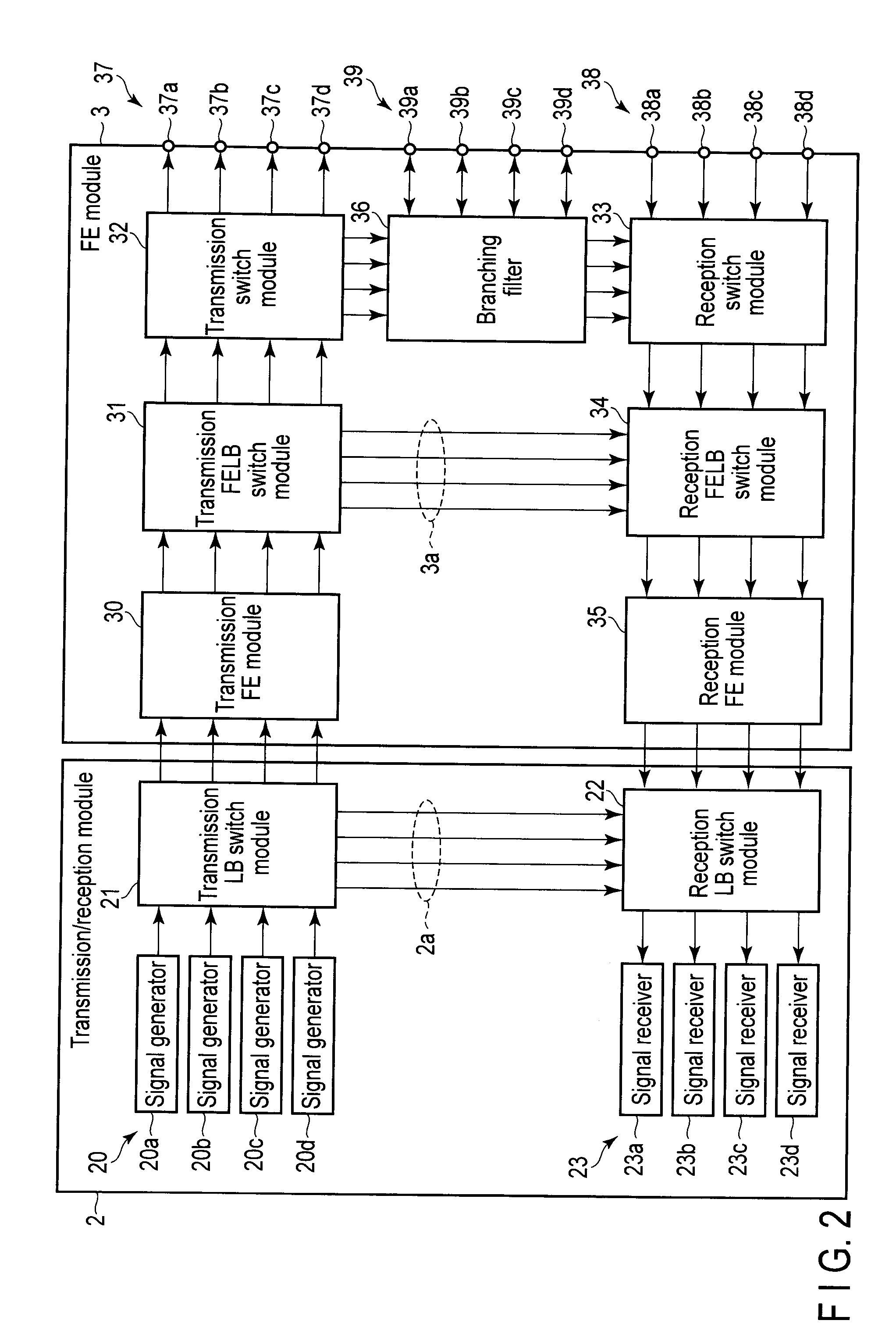

[0101]As shown in FIG. 1, the testing device 1 of the embodiment comprises a transmission / reception module 2, a front end (FE) module 3, a storage module 4, an operation module 5, a control module 6, a display module 7, and input / output terminals 8. The testing device 1 tests a device under test (DUT) 11.

[0102]The testing device 1 also comprises a microcomputer. The microcomputer comprises, for example, a central processing module (CPU), a read only memory (ROM), a random access memory (RAM), an input / output circuit connected to various interfaces, which are not shown. The testing device 1 executes a control program pre-stored in the ROM, thereby causing the microcomputer to function as the transmission / reception module 2, the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com