Pumping device and method for conveying viscous media, in particular adhesives

a technology of viscous media and pumping device, which is applied in the direction of positive displacement liquid engine, piston pump, liquid fuel engine, etc., can solve the problems of complex technical operation, device known from the prior art, and need regular and frequent maintenance, etc., to achieve low maintenance, simple method, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

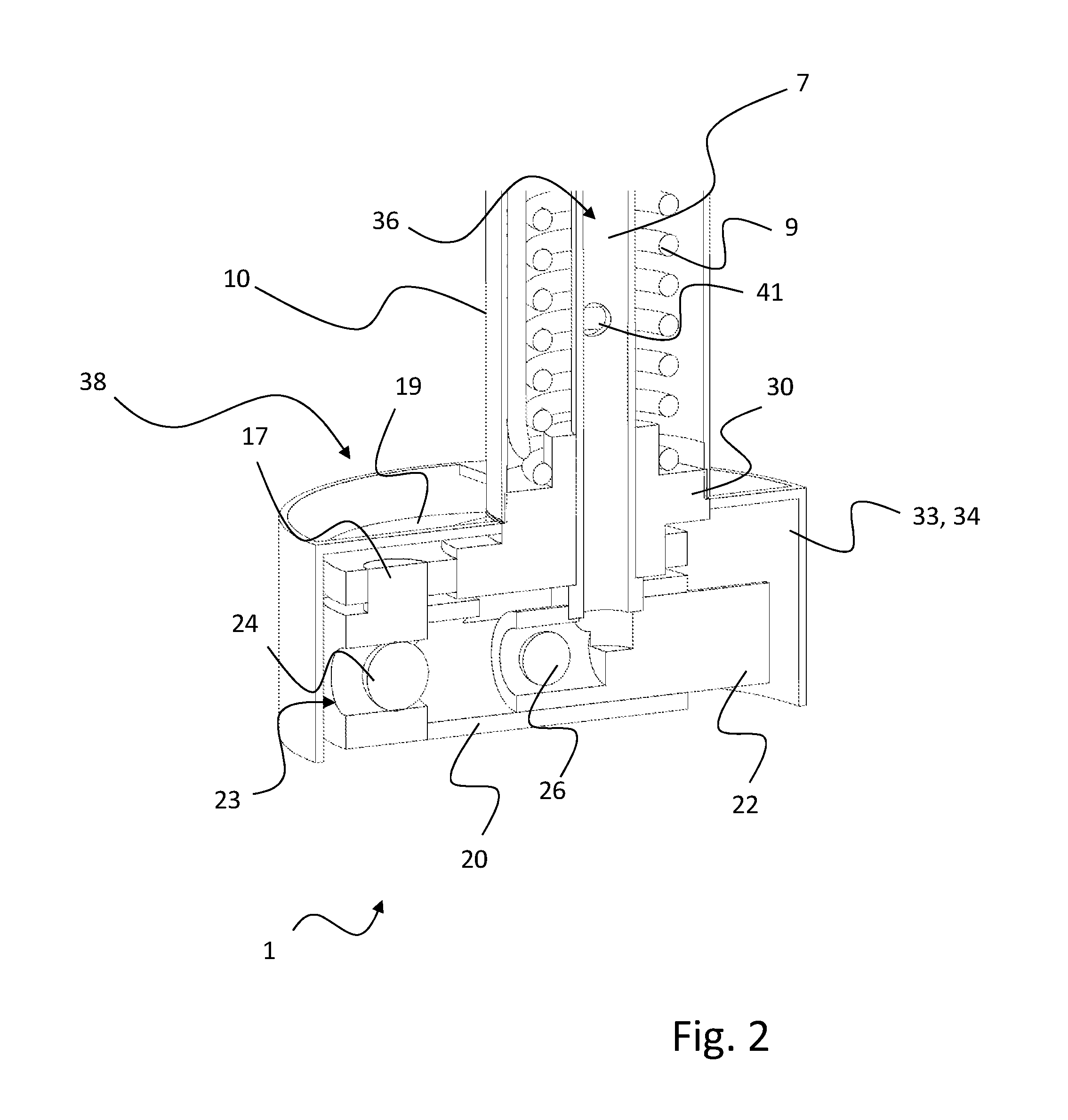

[0044]The same or equivalent elements of the invention are designated by identical reference characters. Furthermore and for the sake of clarity, only the reference characters relevant for describing the respective figure are provided. It should be understood that the detailed description and specific examples of the device and method according to the invention, while indicating preferred embodiments, are intended for purposes of illustration only and are not intended to limit the scope of the invention.

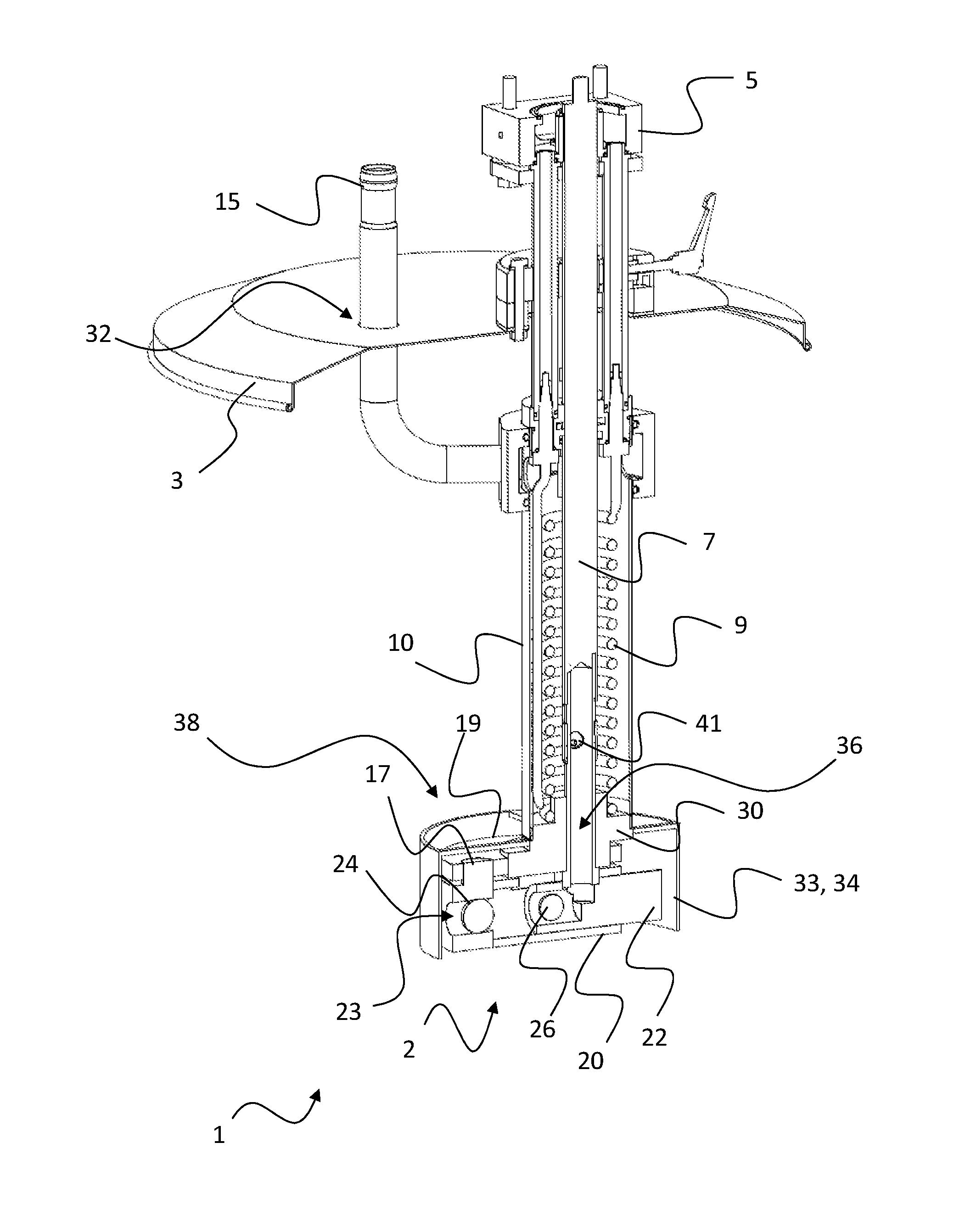

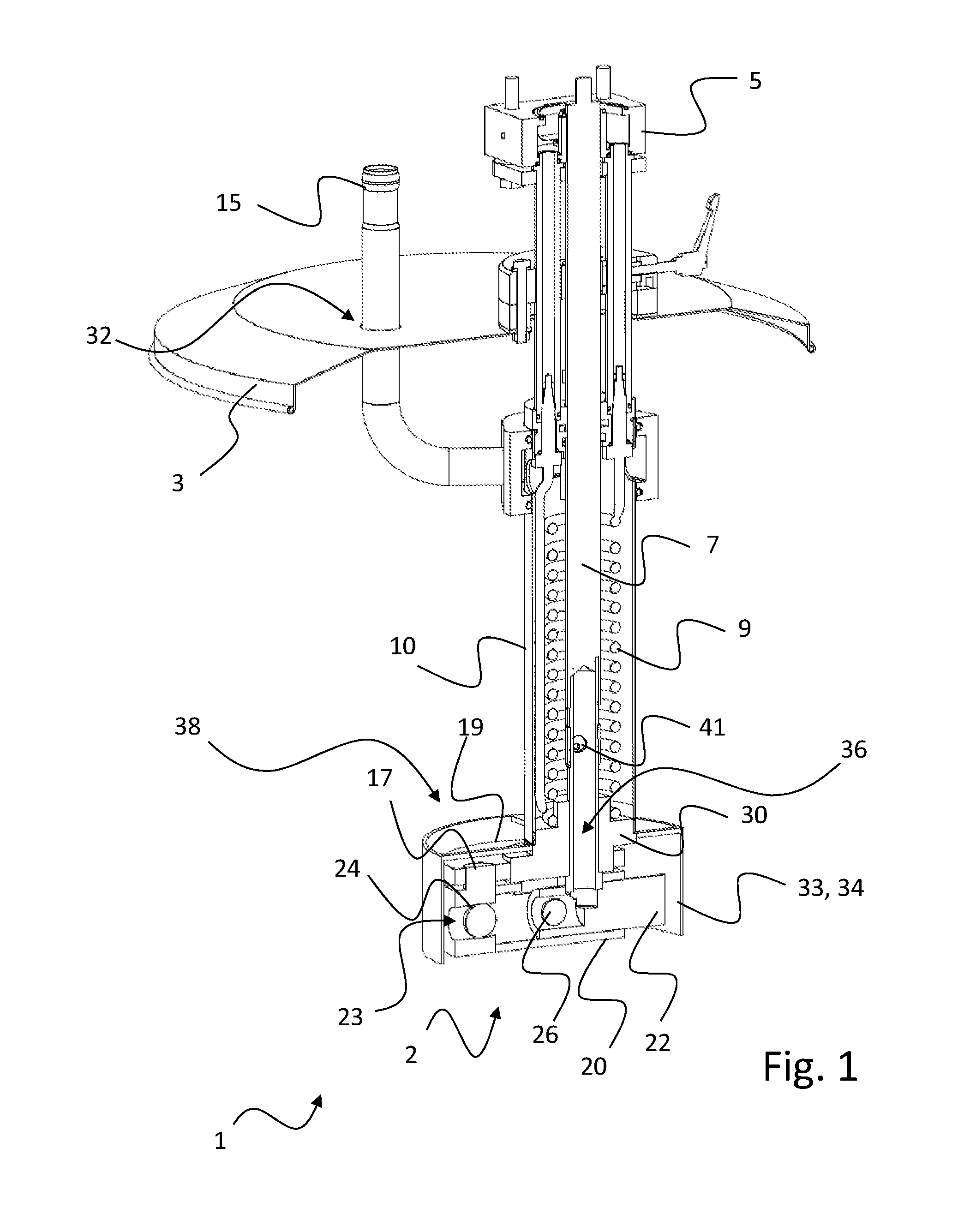

[0045]FIG. 1 shows a schematic and perspective longitudinal cut of an embodiment of a pumping device 1 according to the invention. The pumping device 1 has a bearing housing 5, which is designed for a coupling 55 (cf. FIG. 4)—not illustrated in FIG. 1—being contained within it. An electric motor, for instance, or another drive motor, such as, for instance, a mechanical drive connection or an hydraulically operating motor or the like can be placed or flange-mounted, respectively, onto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com