Method to produce noble metal nanocomposites

a technology of noble metals and nanocomposites, applied in the field of composites, can solve problems such as environmental pollution, and achieve the effect of easy and rapid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

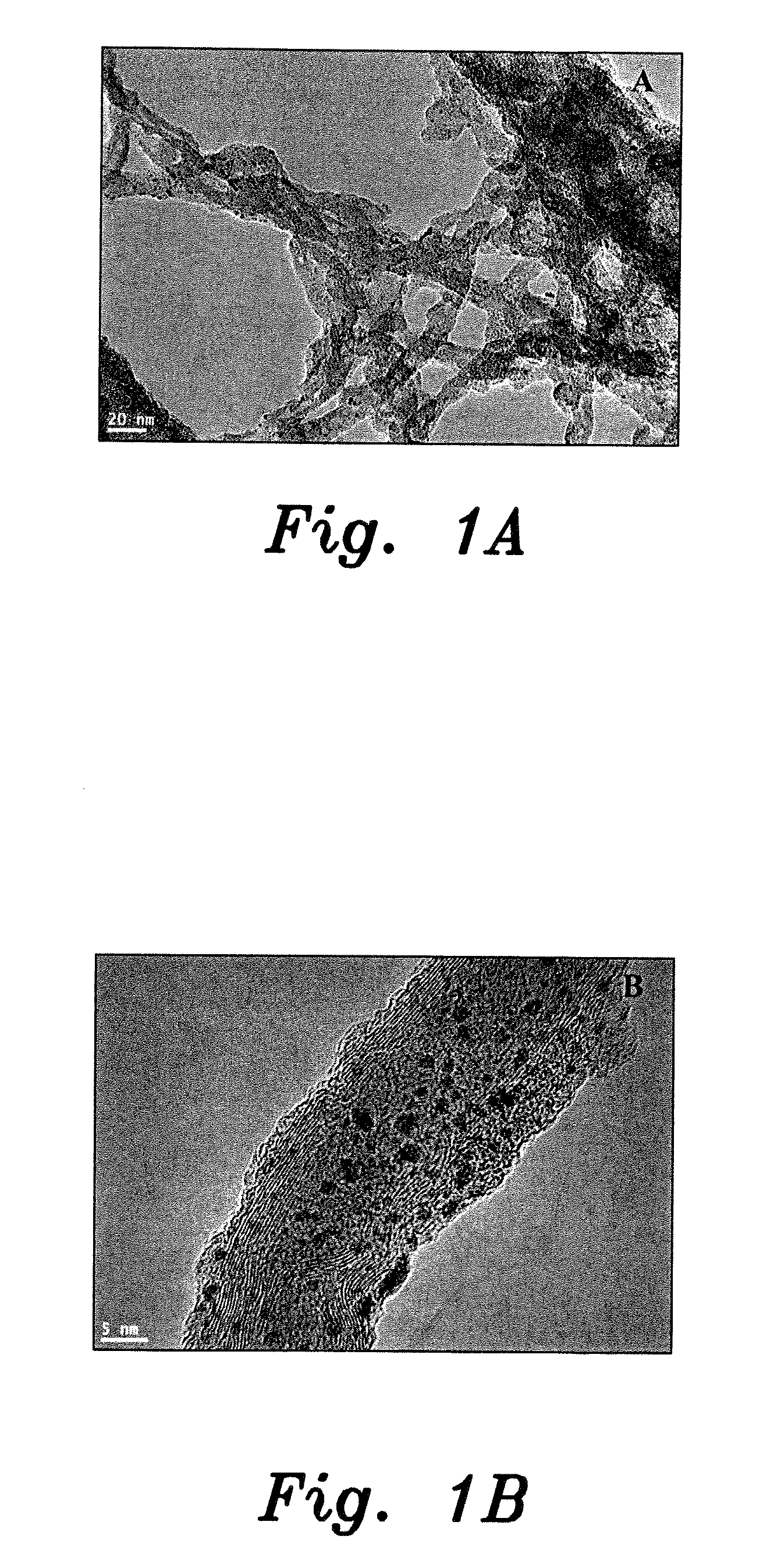

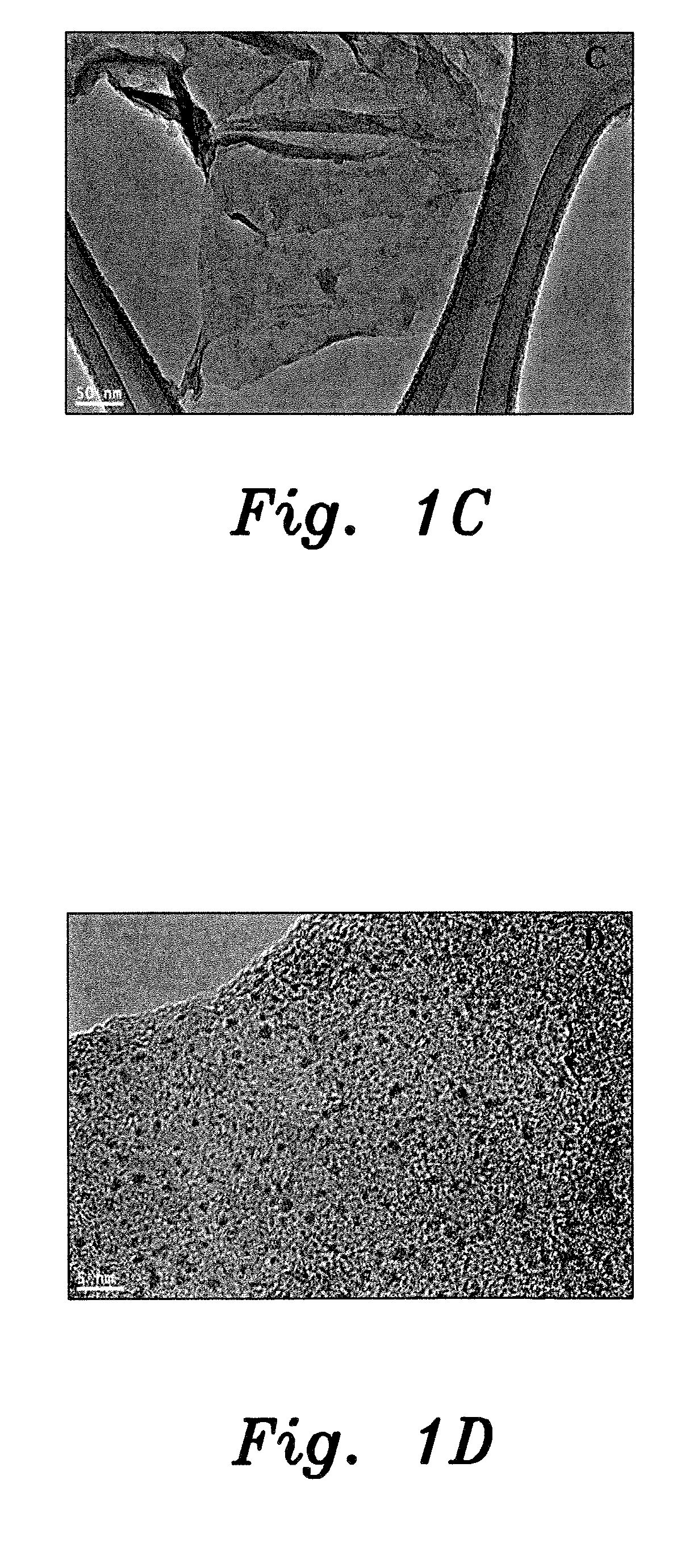

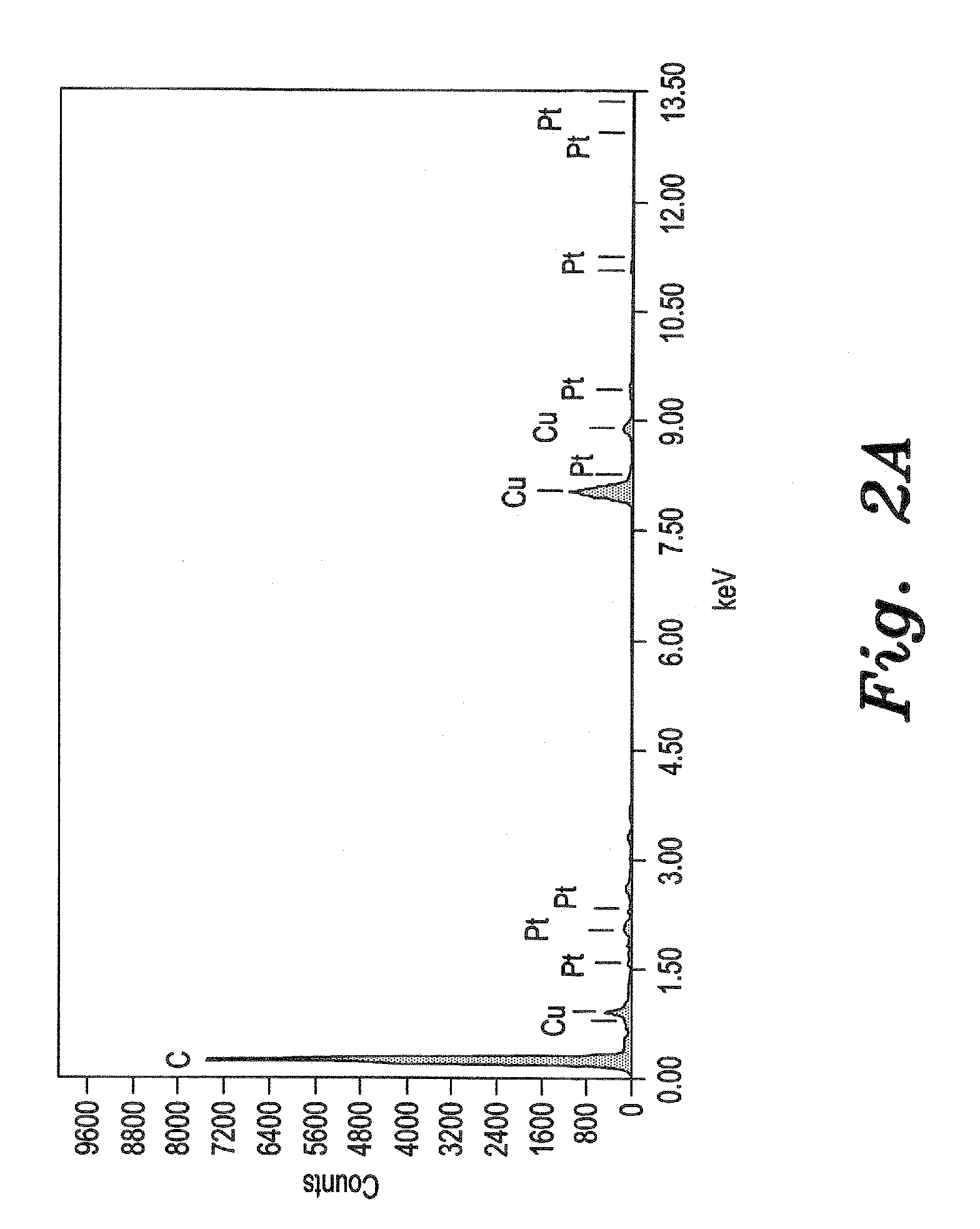

[0027]The method for producing noble metal nanocomposites involves reducing noble metal ions (Ag, Au and Pt) on graphene oxide (GO) or carbon nanotubes (CNT) by using Artocarpus integrifolia leaves extract as a reducing agent. As synthesized MNPs / GO and MNPs / CNT composites have been characterized using X-ray diffraction (XRD), transmission electron microscope (TEM) imaging, and energy dispersive X-ray spectroscopy (EDX). The TEM images of prepared materials showed that the nanocomposites were 2-20 nm in size with spherical nanoparticles embedded on the surface of GO and CNT. This synthetic route is easy and rapid for preparing a variety of nanocomposites. The method avoids use of toxic chemicals, and the prepared nanocomposites can be used for biosensor, fuel cell, and biomedical applications.

[0028]In the following examples, leaves of Artocarpus integrifolia were collected from the Kanyakumari Dist., Tamil Nadu (India). Graphite and CNT were purchased from S.D.Fine, Inida and Sigma,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com