Combined heating and cooling systems

a technology of heating and cooling system and combined heat, which is applied in the direction of heat storage plant, lighting and heating apparatus, heating types, etc. it can solve the problems of inability to control the system, insufficient heating for re-use, and relatively inefficient system, so as to increase the “coefficient of performance” and increase the mass flow of working fluid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example a

Series-Mode Circuit

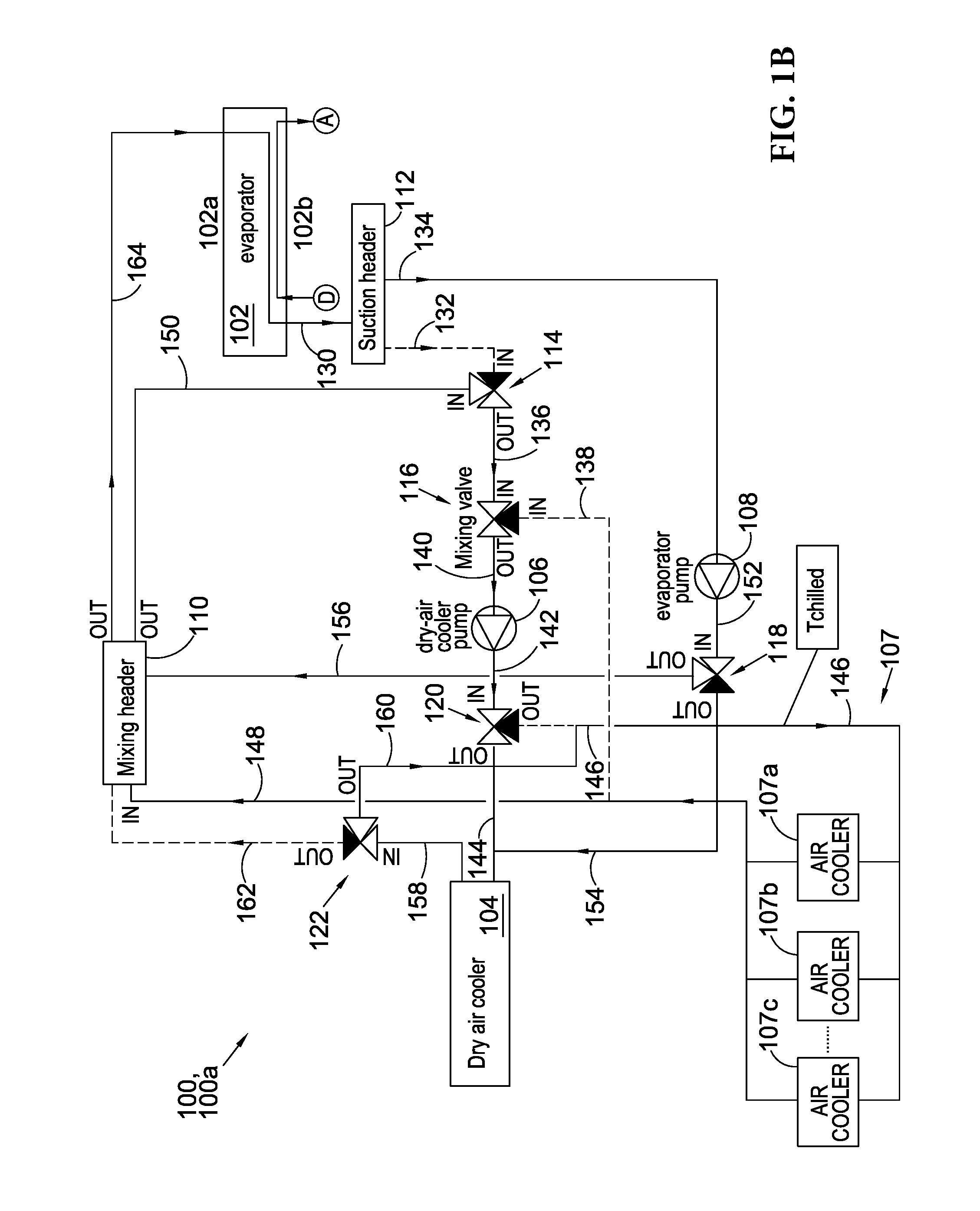

[0117]Referring to FIGS. 8A-8B, which corresponds to FIG. 1B, this example illustrates the effect of using an air blast heat exchanger 104 for cooling during colder weather. FIG. 8A shows temperatures in the system at t=0 minutes and FIG. 8B at t=2 minutes. FIG. 8C corresponds to a version of FIG. 7 and illustrates the main features of a lookup table for control of the (fan of) cooler 104. FIG. 8A corresponds to point a1 in FIG. 8C and FIG. 8B to point a2.

[0118]The target coolant temperature (in the mixing header) is, in this example, 21° C., a temperature suitable, for example, for an industrial process. The ambient temperature is significantly lower than this and if the temperature of the mixing header becomes excessive this can quickly be brought under control by the control of the cooler fan(s), even if the compressor is not providing much cooling effect. As previously discussed, in embodiments the scan rate of the GAM control procedure may be 90 seconds as co...

example b

Parallel-Mode Circuit

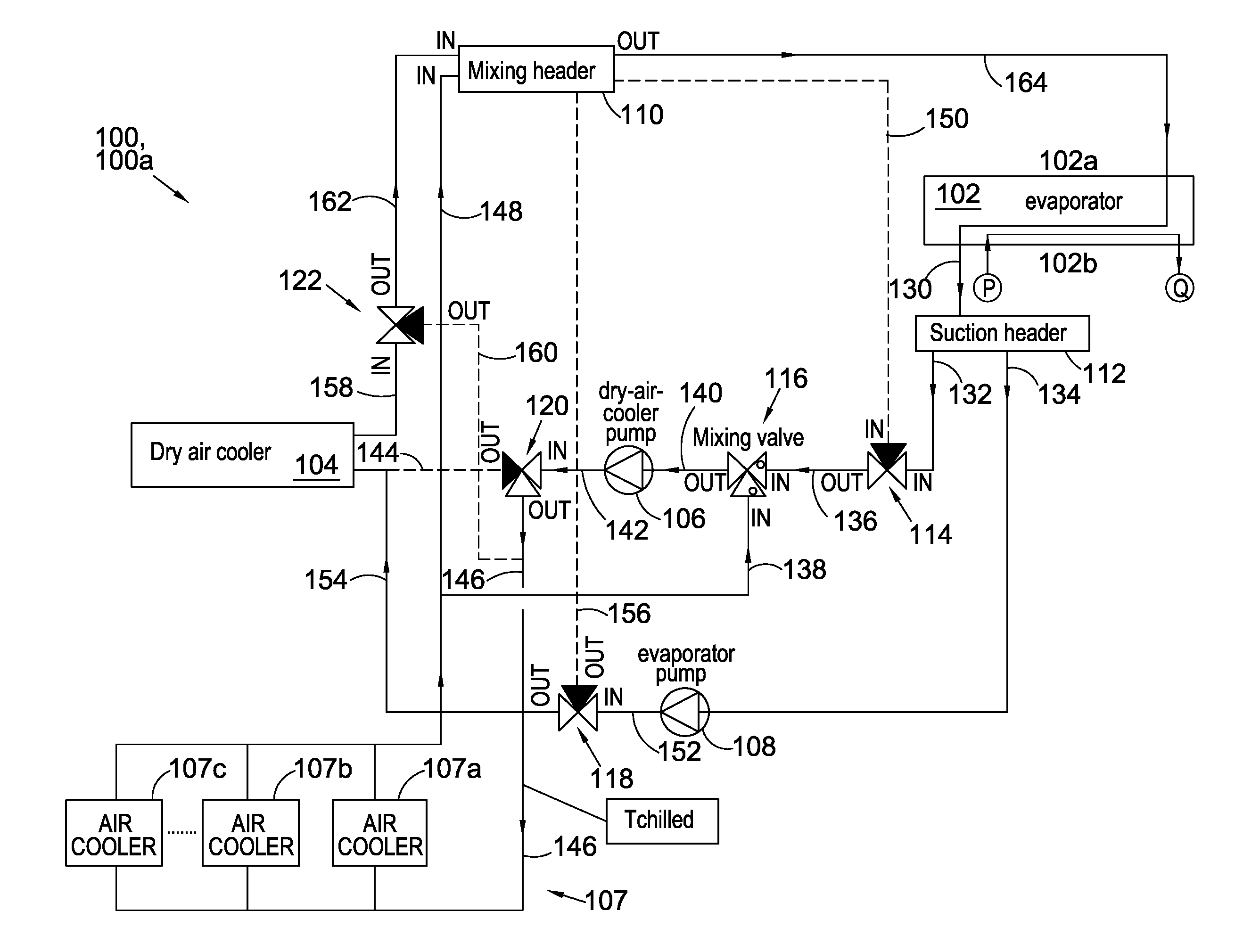

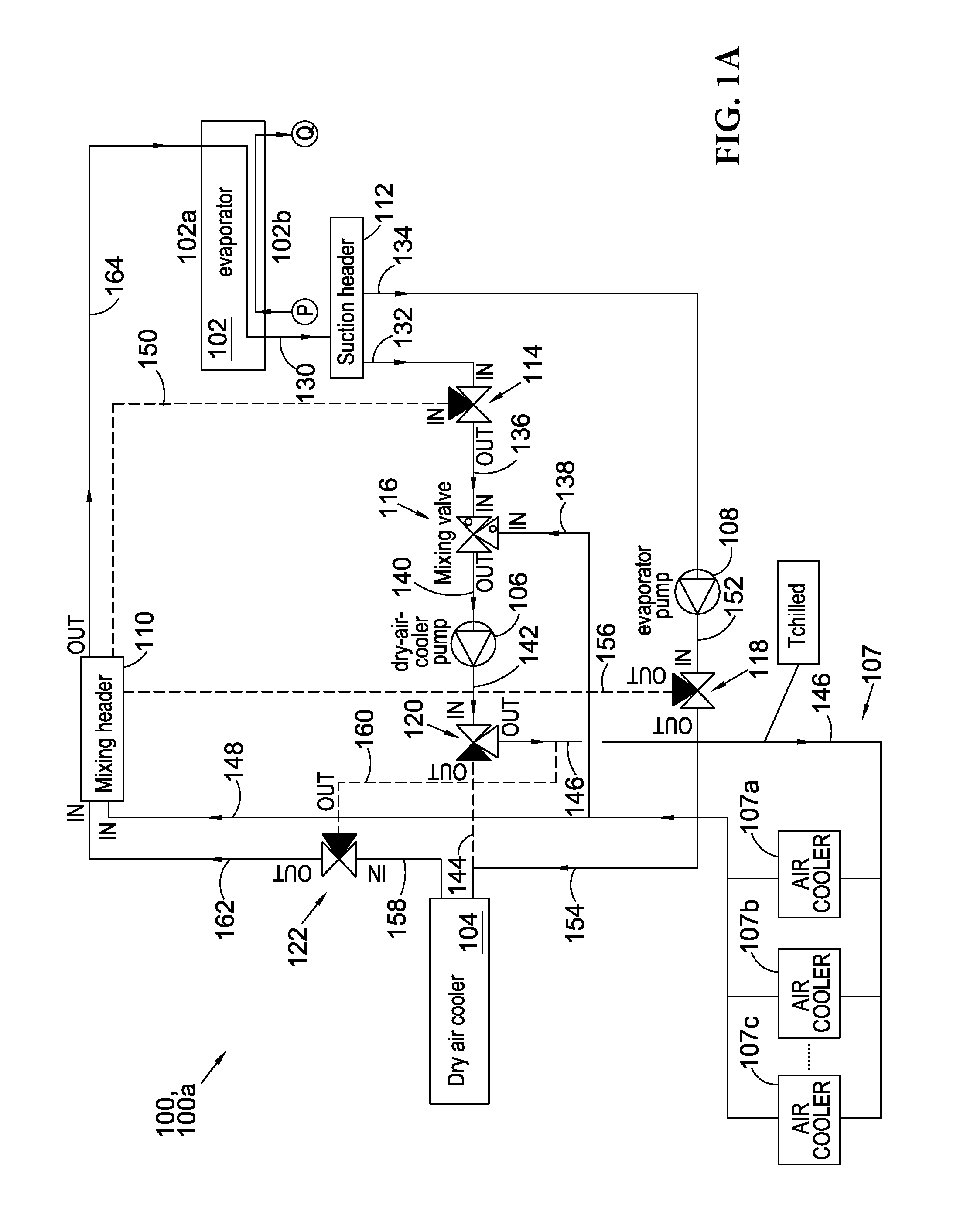

[0119]Referring to FIGS. 9A-9D, which corresponds to FIG. 1A, this example illustrates operation of the system with the cooling side in a parallel mode of operation. Thus FIGS. 9A to 9D show temperatures in the system at, respectively t=0, 6, 12, 18 minutes, and FIG. 9E illustrates the main features of a lookup table for control of the (fan of) cooler 104. In FIG. 9A the recirculation port 138 of mixing valve 116 is closed; in FIG. 9B it is partially open; in FIG. 9C it is wide open; and in FIG. 9D it is partially open once again. The SEL and SCG “gauges” are also illustrated as insets. The target coolant temperature (in the mixing header) is, in this example, 15° C., and the target suction header temperature is 10.0° C. In broad terms, the air blast heat exchanger fan(s) and valves are operated in such a way as to influence the temperature of the mixer header 110. The SCG uses the temperature of the suction header 112 as a means of determining how much or how l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com