Mint-based wrapper for smoking

a tobacco and paper wrapper technology, applied in the field of tobacco wrappers for smoking, can solve the problems of increasing operational complexity and production costs, undesirable compounds in combustion, and degrading the final paper quality, and achieve the effect of enhancing the taste of smoking articles and reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

Discussion

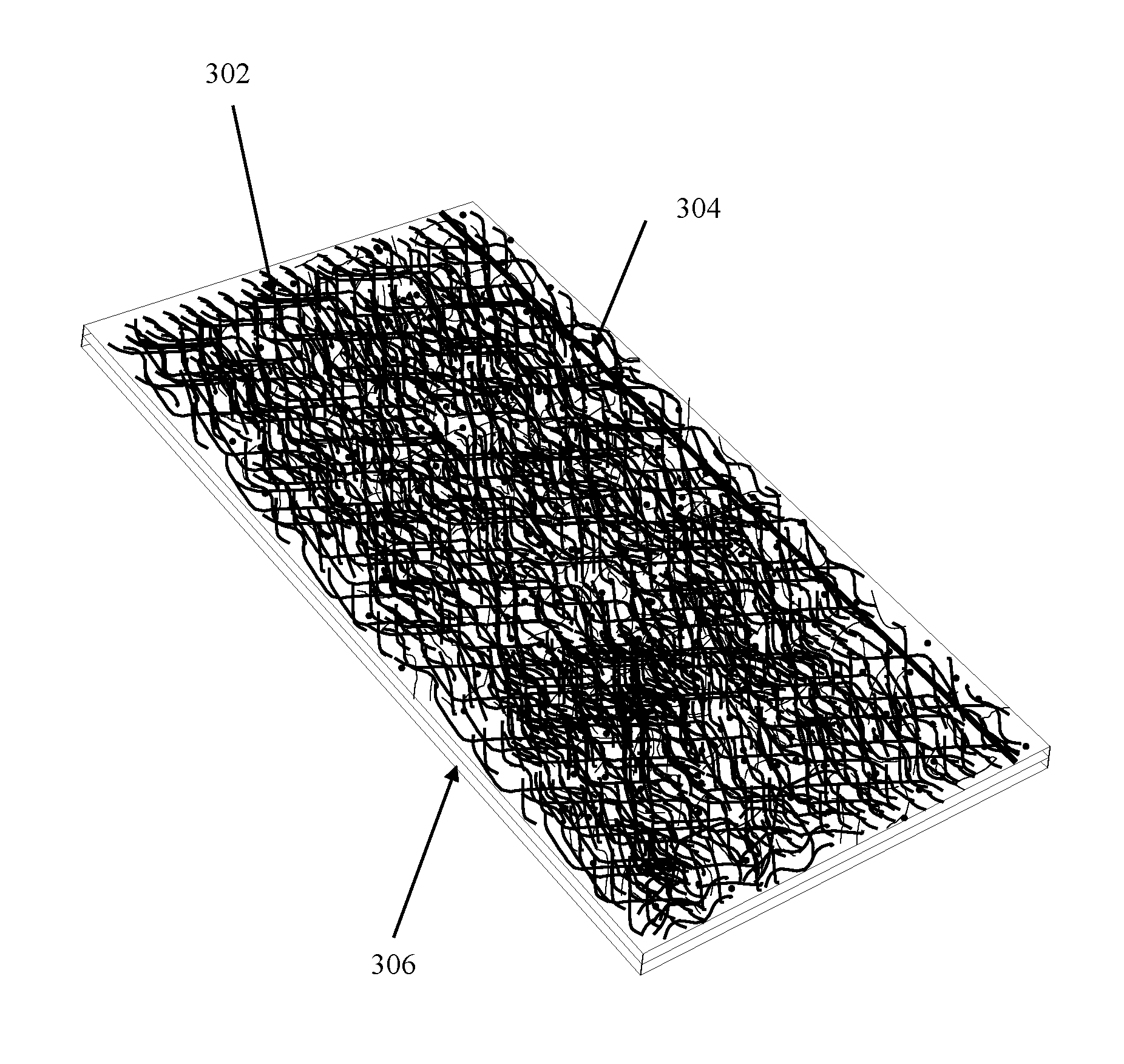

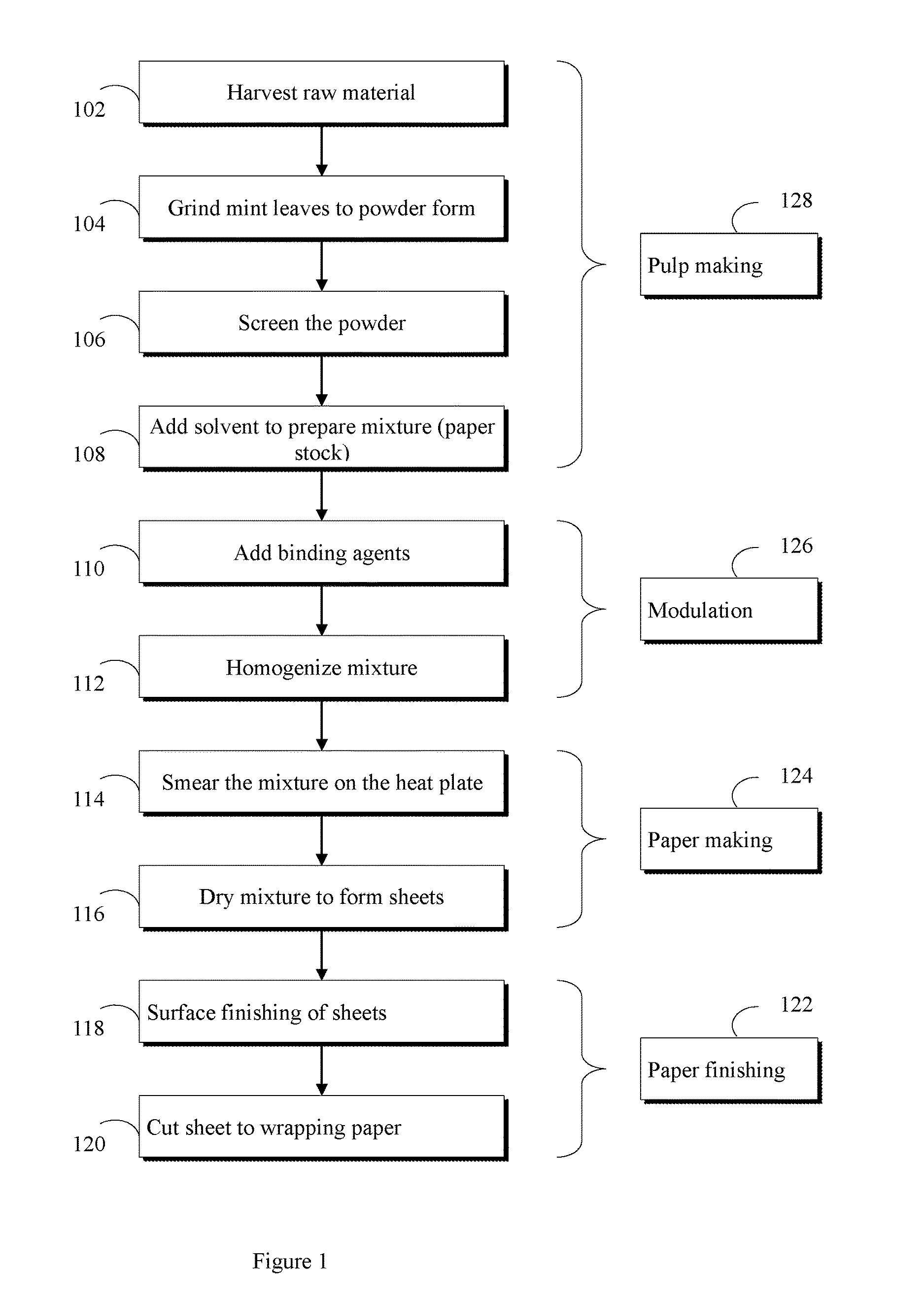

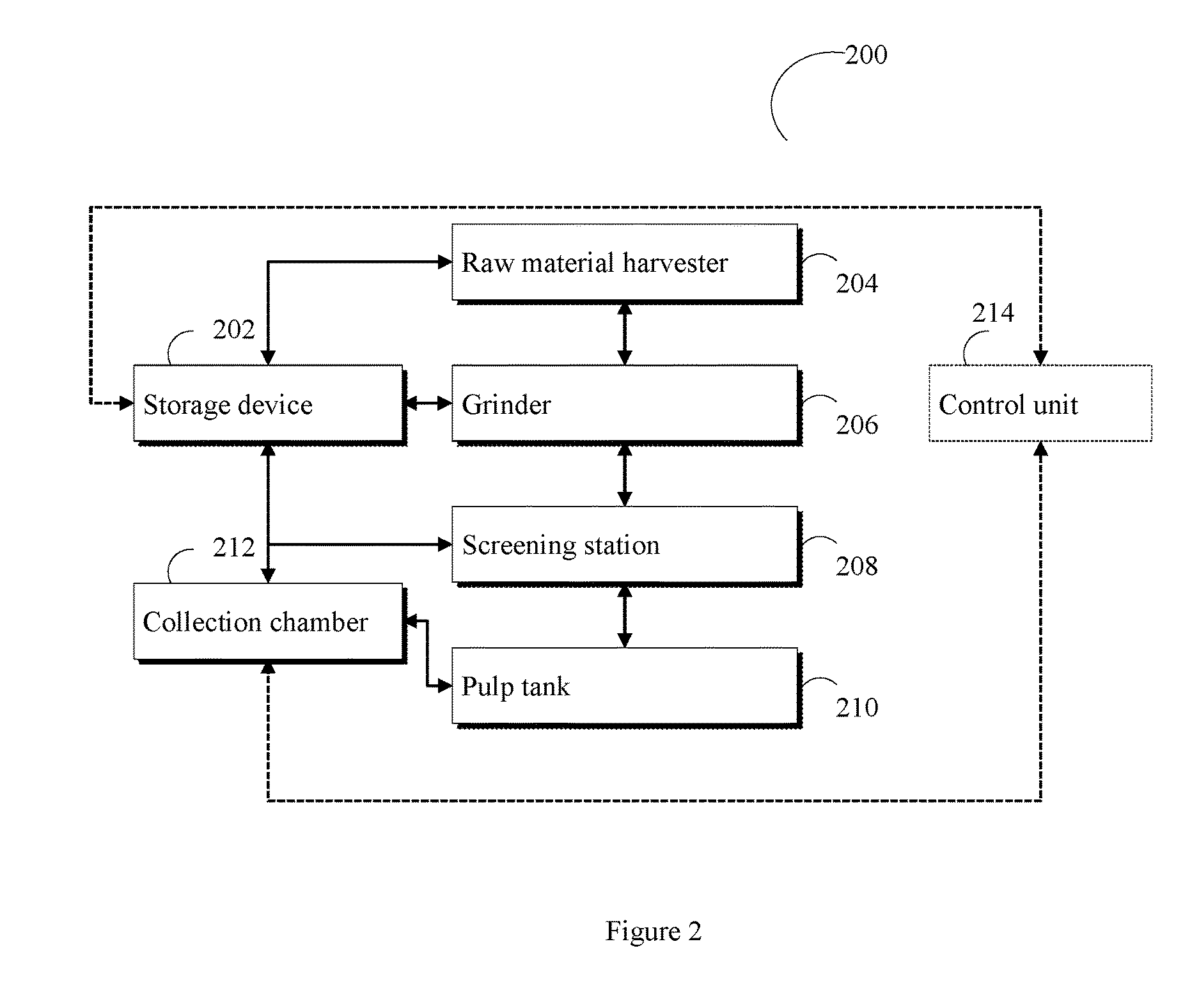

[0030]The invention can be understood better by examining the FIGS. 1 through 5, wherein FIG. 1 illustrates an exemplary process flow diagram for manufacturing a wrapper paper according to the teachings of the invention. FIG. 2 illustrates a pulping system according to the present invention and FIG. 3 illustrates a homogenized wrapping sheet made from mint-based fiber pulp for smoking articles.

[0031]In FIG. 1, a raw material obtained from natural resources is processed using four steps—pulp preparation 128, modulation 126, papermaking 124, and paper finishing 122—to manufacture the wrapping paper for the smoking article. The composition of the resultant wrapping paper contains herbal mint to impart a pleasant aroma to the side-stream smoke during consumption. The herbal mint paper, as per disclosure, is a mint-based wrapping paper that burns more slowly, coolly, and smoothly than existing papers, and reduces the risk of harmful chemicals.

Pulp Preparation

[0032]The pulp prep...

example 1

[0051]The homogenized pulp mixture is prepared from the following ingredients:

[0052]Herbal mint leaves—60%

[0053]Cellulose fiber—18%

[0054]Methylcellulose—10%

[0055]Guar gum—10%

[0056]Glycerol—2%

[0057]The herbal mint is harvested from the leaves of the plant and dried to remove water from them. Using a grinder, the leaves are powdered to granular form. The mint powder is added to the water solution (which acts as a solvent), methylcellulose (acts as a thickening agent), gaur gum (binding agent), and glycerol (modifier and humectant) to prepare the homogenized mixture.

[0058]The mixture is passed through machine rollers to form a base sheet with the desired thickness, and the said base sheet is dried on a heat plate to obtain the paper sheet. Thereafter, the paper sheet is cut into the desired length to manufacture the wrapping paper for smoking articles.

example 2

[0059]The homogenized pulp mixture is prepared from the following ingredients:

[0060]Flavoring agent from a plant belonging to genus Mentha and contributing 58.5-61.5% to the composition; it enhances the flavor of the side smoke in the smoking article during consumption.

[0061]Cellulose fiber sourced from any fibrous leaf in the range of 17.5-18.5; it binds fiber with glue to reduce combustion speed.

[0062]Naturally occurring fiber thickening agent in the range of 9.5-10.5%; it binds fibers to hold paper.

[0063]Naturally occurring binding substances in the range of 9.5-10.5%; they provide strength and slow combustion.

[0064]Naturally occurring modifier and humectant substance in the range of 1.5-2.5%; it controls the combustion properties.

[0065]The flavoring agent is harvested from the leaves, roots, and stems, and dried in shadow places to yield higher amount of mint. The dried mint is powered by the mechanical pulping apparatus. The mixture is added with the water solution and other in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| mechanical force | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com