Press-granulating process of non-ductile salts

a press-granulating and non-ductile salt technology, applied in the field of press-granulating non-ductile salts and salt mixtures, can solve the problems of inability to press hard salts, inability to work with salts which are difficult to press, and need an additional thermal drying treatment for rolling granulates, etc., to achieve high efficiency and cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

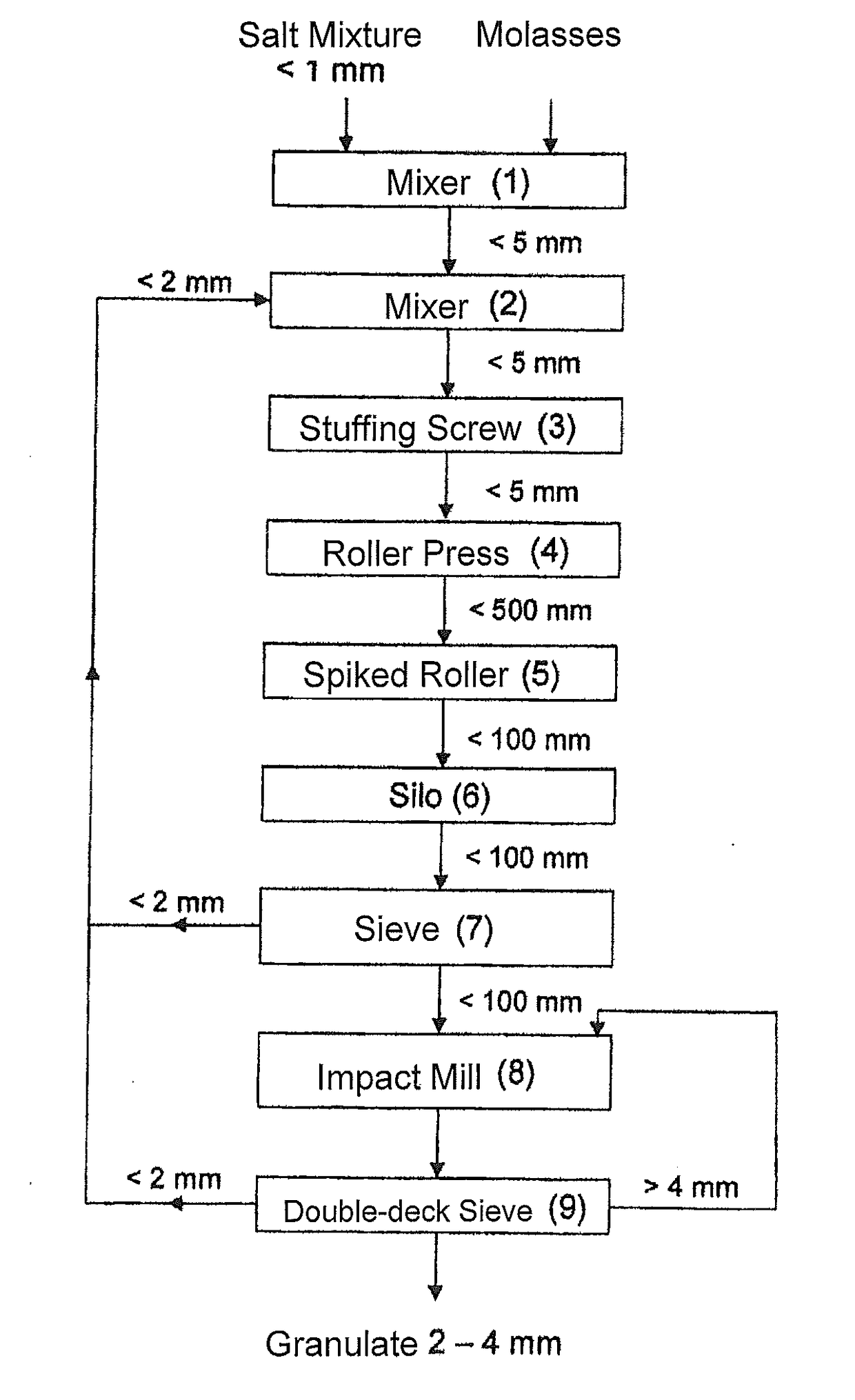

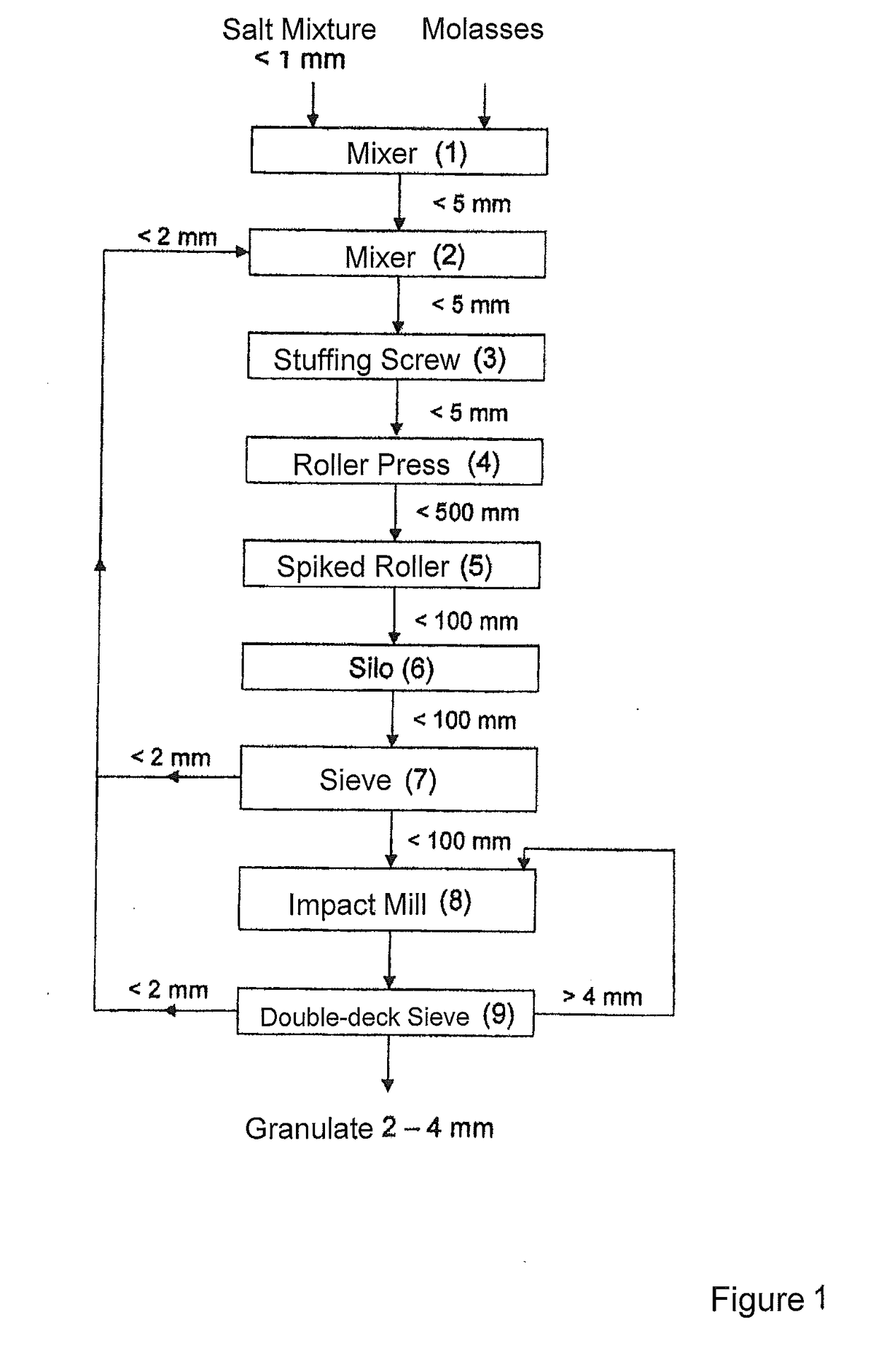

example 1 (see fig.1)

Example 1 (SEE FIG. 1)

[0015]5 tons of a mixture of 70 parts kieserite, 22 parts langbeinite, 6 parts anhydride and 2 parts clay minerals with a grain size of 95%1) until a homogenous distribution is obtained. Occasionally, agglomerates up to 5 mm are formed. The temperature of the mixture shall be 2) with fine grains from the product sieving which is fed back into the process, and is fed back into the pressing cycle. The material which has been pre-compressed in a stuffing screw (3) is fed into the roller press (4) with counter-rotating compacting rollers, and is compacted using pressures from 200 to 250 bar. An about 7 to 20 mm strong foil is obtained, which is continually formed next to small parts of non-pressed fine salt. Since the press scrubs are initially very soft, the mixture of scrubs and fine grains is pre-crushed using a spiked roller (5) into parts being at maximum 10×10 cm of size, stored in a Silo (6) for at least 3 to 4 hours, and afterwards the cured mixture is siev...

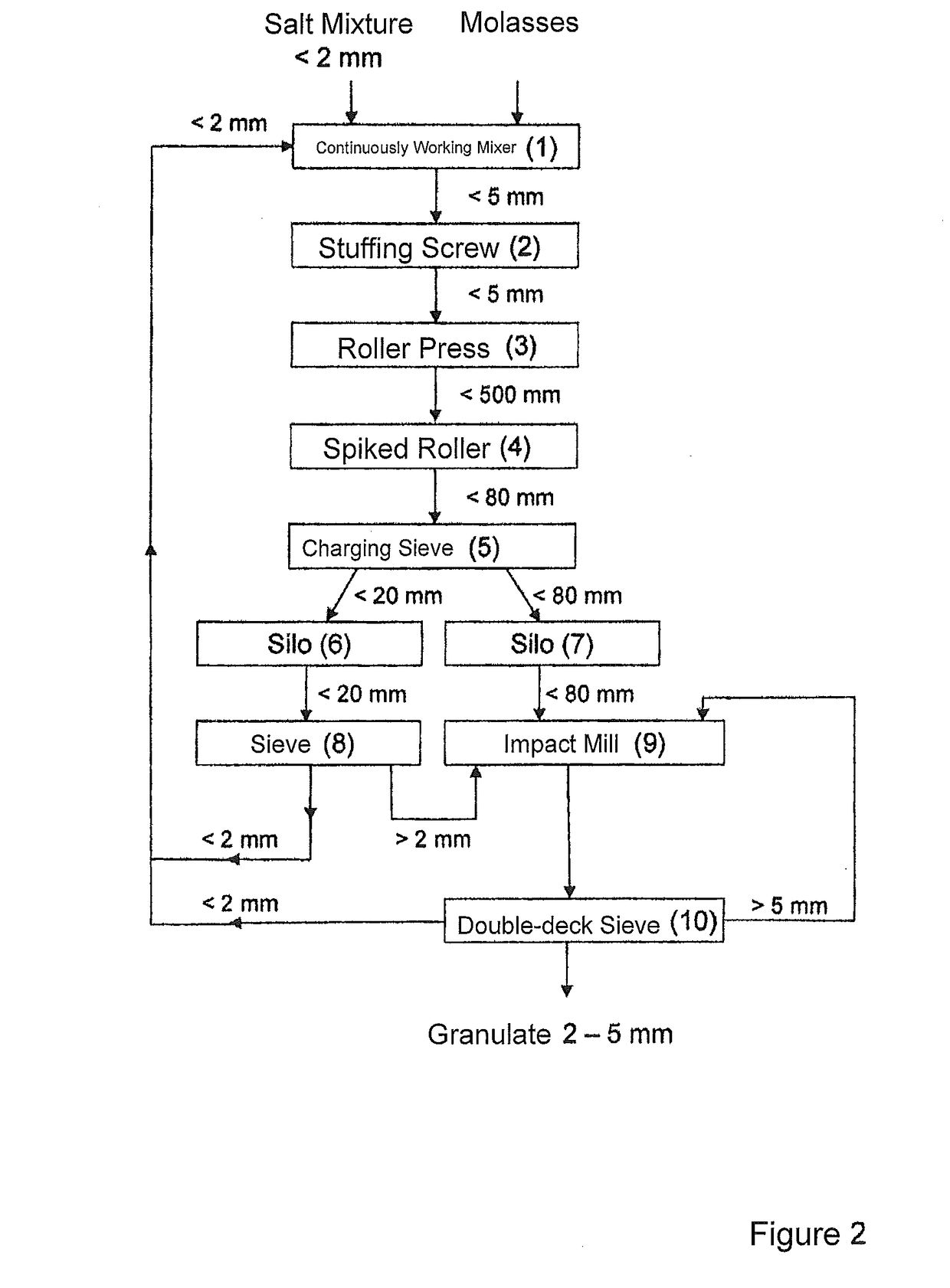

example 2 (see fig.2)

Example 2 (SEE FIG. 2)

[0018]20 tons of polyhalide (K2504.MgSO4.2CaSO4.2H2O) from a natural resource is mixed with an additive of 4 to 4.6% by mass of sugar beet molasses and a total sugar amount of 47% in the dry matter. The mixture of the finely grained mineral salt with a grain size of 0 to 2 mm and the molasses occurs at environmental temperature in a continuously working mixer (1) in throughput. To said continuously working mixer (1), the sieved fine grain from the granulate sieving is added. Said mixture is fed to the press rollers of the roller press (3) via a stuffing screw (2), wherein press pressures up to 280 bar result at first in soft scraps, which, after pre-crushing in a spiked roller (4) is obtained in form of palm-sized parts. Said mixture, after passing a charging sieve (5) is separated into two streams. The screen underflow, which consists of non-pressed material and smaller scrap parts, is transferred into a separate maturing silo (6), the large scraps are transfe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com