Process for the production of a ready to eat shelf-stable packaged focaccia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

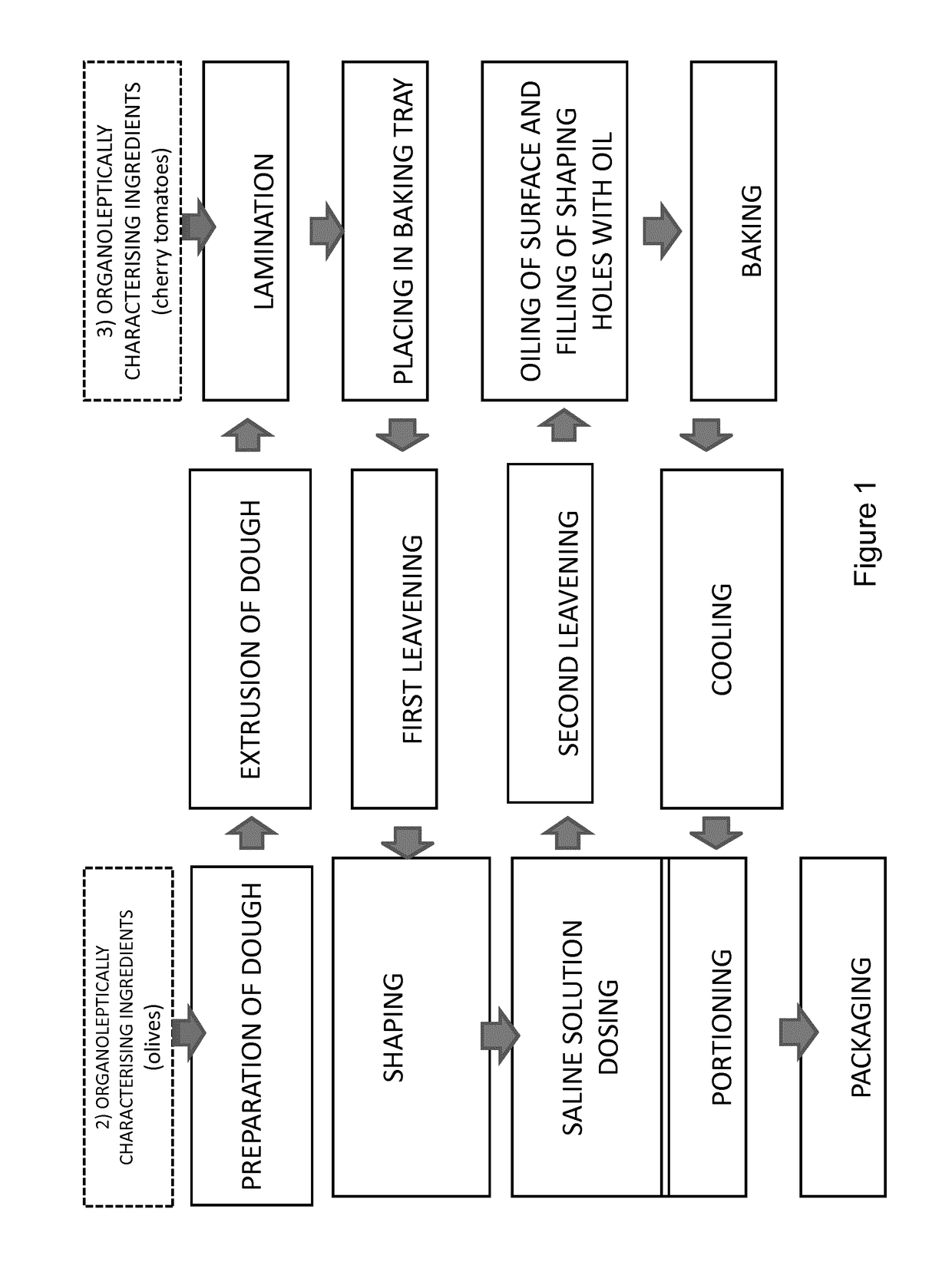

Method used

Image

Examples

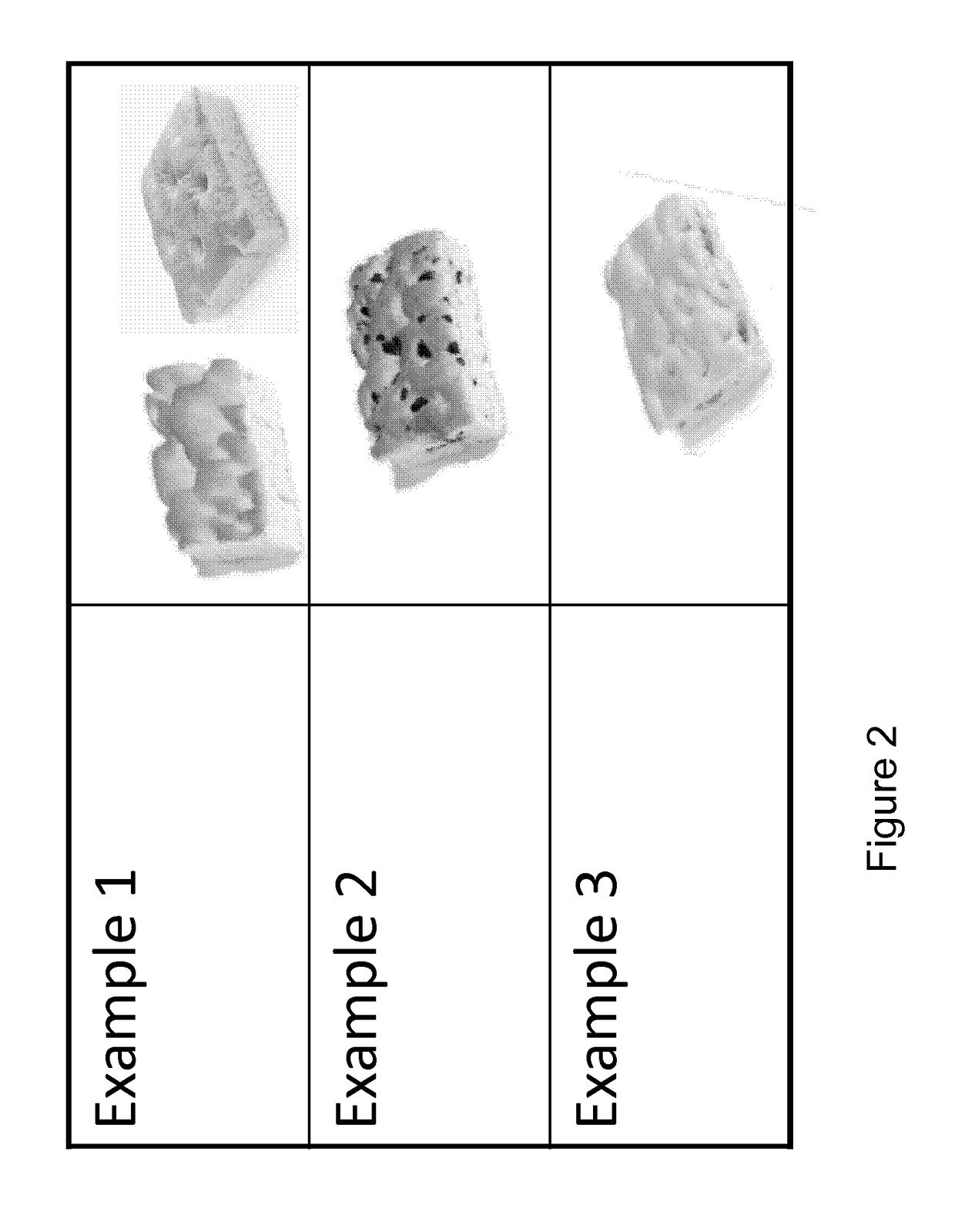

example 1

Plain Focaccia

[0134]In a first kneading step, a dough for focaccia was prepared with the ingredients given in Table 1, in the quantities indicated, in a mixer with spiral hook at a speed of the stirrer of 35 rpm for 5 minutes in environment set to a temperature of 25° C. To this, in a second kneading step, at 75 rpm for 7 minutes, the ingredients listed in Table 2 were then added in the quantities indicated. At the end a dough with total weight of 2.5 kg was obtained.

TABLE 1Formulation of the dough of the first kneading step% basedon theIngredientstotalType 0 wheat flour53.57Ascorbic acid0.05Malted barley flour0.38Gluten0.63Fatty acid monoglycerides0.40Water30.00Guar fibre0.91Powder natural yeast1.05starterFlavourings0.15Alpha-amylase0.02

TABLE 2Ingredients added in the second kneading stepExtra virgin olive oil1.46Palm fat8.05Natural yeast1.83Salt1.50Total:100%

[0135]The raw dough for focaccia thus obtained was subjected to an extrusion step with a model V4 extruder produced by Rheon...

example 2

[0147]Olive Flavoured Focaccia with Olives

[0148]This focaccia was prepared by following the same process of Example 1 with the difference that in the first kneading step a dough was prepared based on the ingredients listed in Table 3. To this dough, the ingredients listed in Table 4 were added in the second kneading step.

TABLE 3Formulation of the dough of the first kneading step% basedon theIngredientstotalType 0 wheat flour51.54Ascorbic acid0.05Malted barley flour0.36Gluten0.61Fatty acid monoglycerides0.63Water24.70Guar fibre0.35Powder natural yeast1.01starterFlavouring0.21Alpha-amylase0.02

TABLE 4Ingredients added in the second kneading stepExtra virgin olive oil1.41Palm fat4.23Natural yeast1.76Salt1.73Sliced frozen black olives11.39Total:100%

[0149]Upon the focaccia exiting the oven the thickness was approximately 25 mm and the depth of the shaping holes was approximately 24 mm.

[0150]At the end of baking and cooling on a baking rack, the product was cut by ultrasounds and portioned...

example 3

Tomato Flavoured Focaccia

[0151]This focaccia was prepared by following the same process of Example 1 with the difference that in the first kneading step a dough was prepared based on the ingredients listed in Table 5. To this dough, in the second kneading step, the ingredients listed in Table 6 were added, and with the difference that in the step of overlaying of the 4 sheets of dough a quantity of 8% by weight (with respect to the dough) of fragmented and IQF osmotically dehydrated cherry tomato was dosed between two sheets (see Table 7).

TABLE 5Formulation of the dough of the kneading step% basedon theIngredientstotalType 0 wheat flour48.1Ascorbic acid0.06Malted barley flour0.69Gluten0.57Fatty acid monoglycerides0.46Water27.9Guar fibre0.83Powder natural yeast0.95starterPizza flavouring0.05Alpha-amylase0.02

TABLE 6Ingredients added in the second kneading stepExtra virgin olive oil1.33Palm fat7.35Natural yeast2.05Salt1.64

TABLE 7Ingredients added in the lamination stepFragmented and IQ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com