Chemically strengthened glass and methods of making same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]It is to be appreciated that the invention is not limited to the specific apparatus and / or methods illustratively shown and described herein. Moreover, it will become apparent to those skilled in the art given the teachings herein that numerous modifications can be made to the embodiments shown that are within the scope of the claimed invention. Thus, no limitations with respect to the embodiments shown and described herein are intended or should be inferred.

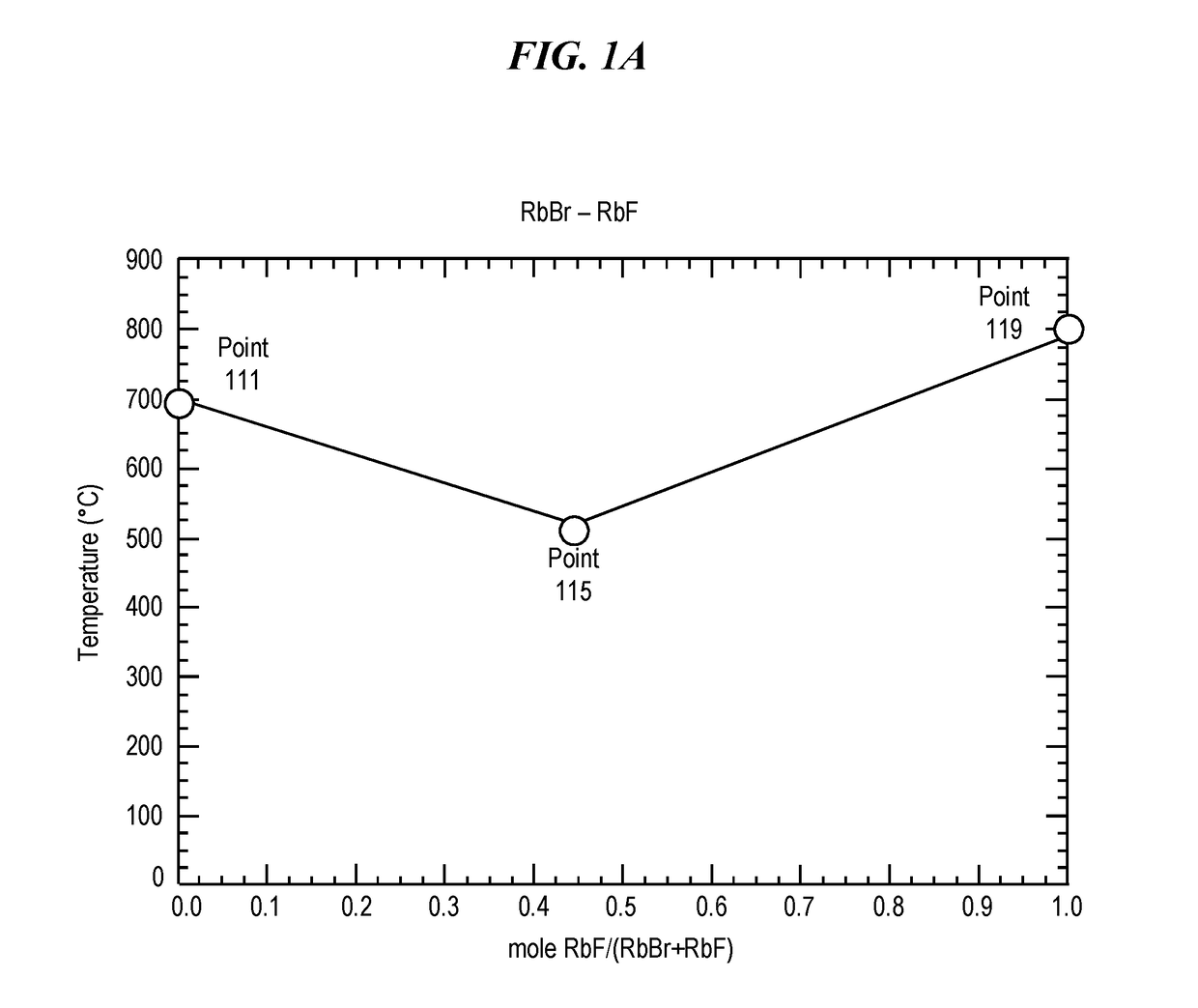

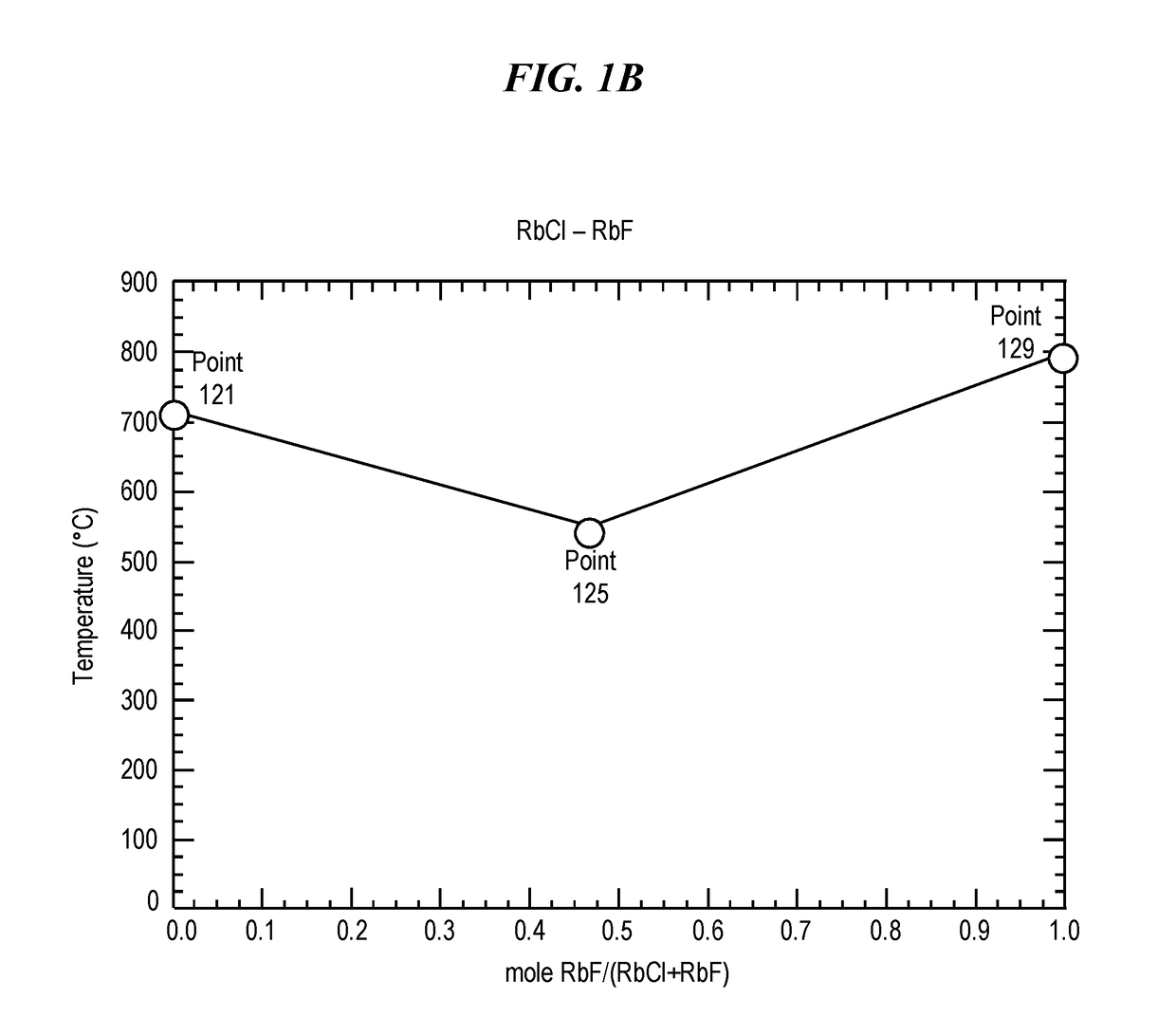

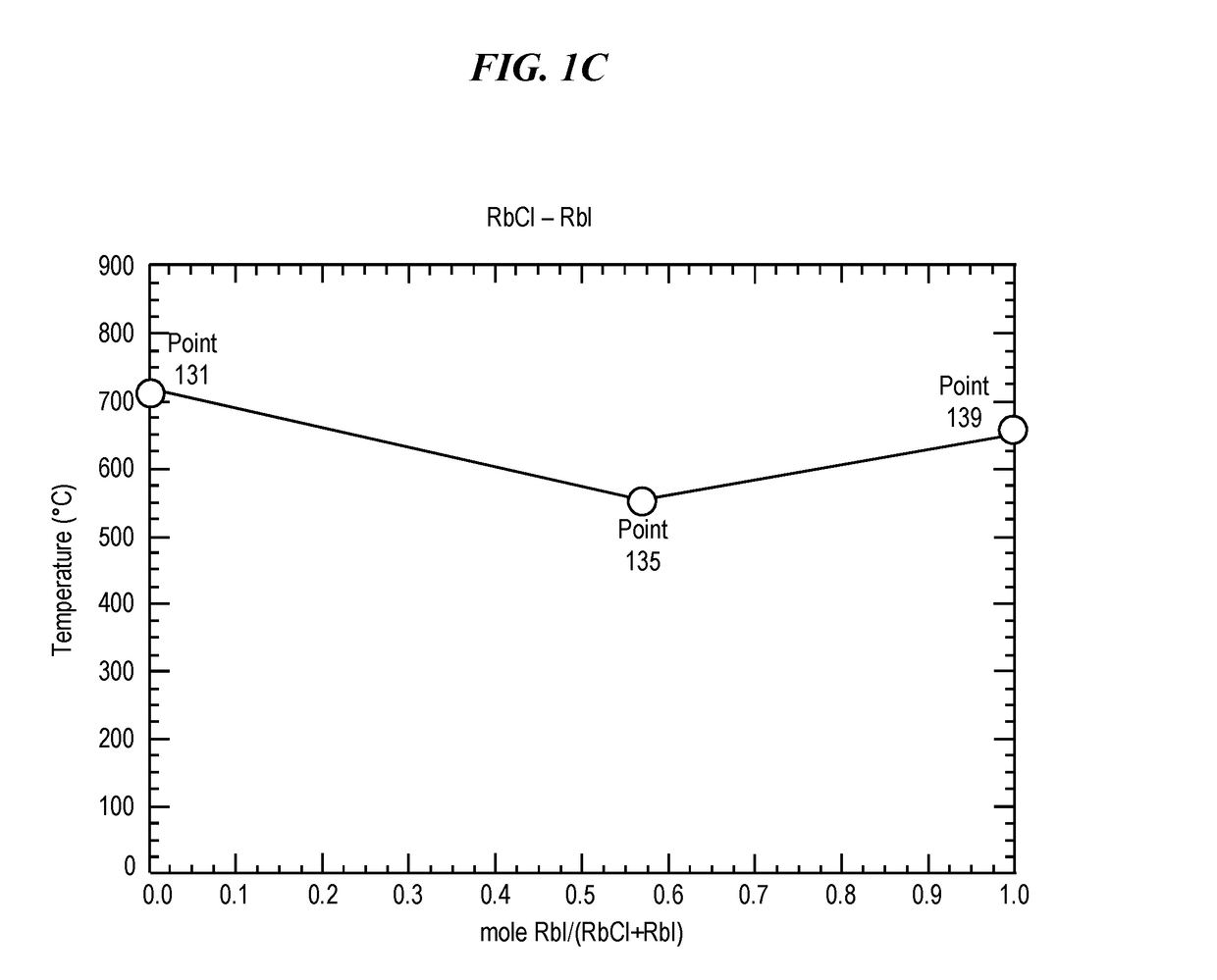

[0041]As previously noted, conventional techniques for strengthening glass involve substituting sodium (Na) ions with larger potassium (K) ions. Like sodium and potassium, rubidium (Rb) is an alkali metal found in Group I of the periodic table. However, rubidium is larger than potassium, which as noted above is larger than sodium. Thus, treating glass with rubidium salts will produce an even greater size expansion and a correspondingly greater increase in compressive stress tolerance than conventional treatment with potass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap