Steel material and expandable oil country tubular goods

a technology of expandable oil country tubular goods and steel materials, which is applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of increasing drilling cost and construction period, and achieve excellent ssc resistance, high expandability, and uniform elongation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0143]Twenty-three kinds of steels of A to P and AA to AG having the chemical compositions given in Table 1 were melted in a 50 kg vacuum furnace to produce ingots. Each of the ingots was heated at 1180° C. for 3 h, and thereafter was forged and cut by electrical discharge cutting-off. Thereafter, the cut ingots were further soaked at 1150° C. for 1 h, and were hot-rolled into plate materials having a thickness of 20 mm. Subsequently, the plate materials were subjected to solid solution heat treatment at 1100° C. for 1 h to obtain test materials (test Nos. 1 to 23). Additionally, test materials produced in the same manner as test Nos. 1 to 23 are further cold-rolled at a working ratio of 10% to obtain strengthened test materials (test Nos. 24 to 46).

TABLE 1Chemical composition (in mass %, balance: Fe and impurities)SteelCSiMnAlPSCuNVCrMoA1.210.2926.120.0330.0120.0061.480.013———B1.190.3036.000.0360.0100.0061.510.012———C1.160.2725.950.0280.0140.0040.910.013———D1.210.2826.130.0310.0130...

example 2

[0156]Effects of aging heat treatment after solid solution treatment were investigated using steels K, L, O and AF which were prepared in EXAMPLE 1. The condition of solid solution heat treatment is same as EXAMPLE 1. Additionally the aging heat treatment is performed under the condition of 800° C. and 1 hour. The method for evaluation test was same as EXAMPLE 1.

[0157]Metal micro-structures of the aging heat treated test materials before and after the cold working at the working ratio of 25% were investigated by using the ferrite meter as is the case with EXAMPLE 1. For all of the test materials before the cold working, the phases having BCC structures could not be detected and the metal micro-structures were austenite single phases. Therefore, the volume amounts of the phases having BCC structures for the test materials only after the cold working are shown as a BCC ratio by volume % in tables. The results are given in Table 4.

TABLE 4After aging heat treatmentAfter simulated expans...

PUM

| Property | Measurement | Unit |

|---|---|---|

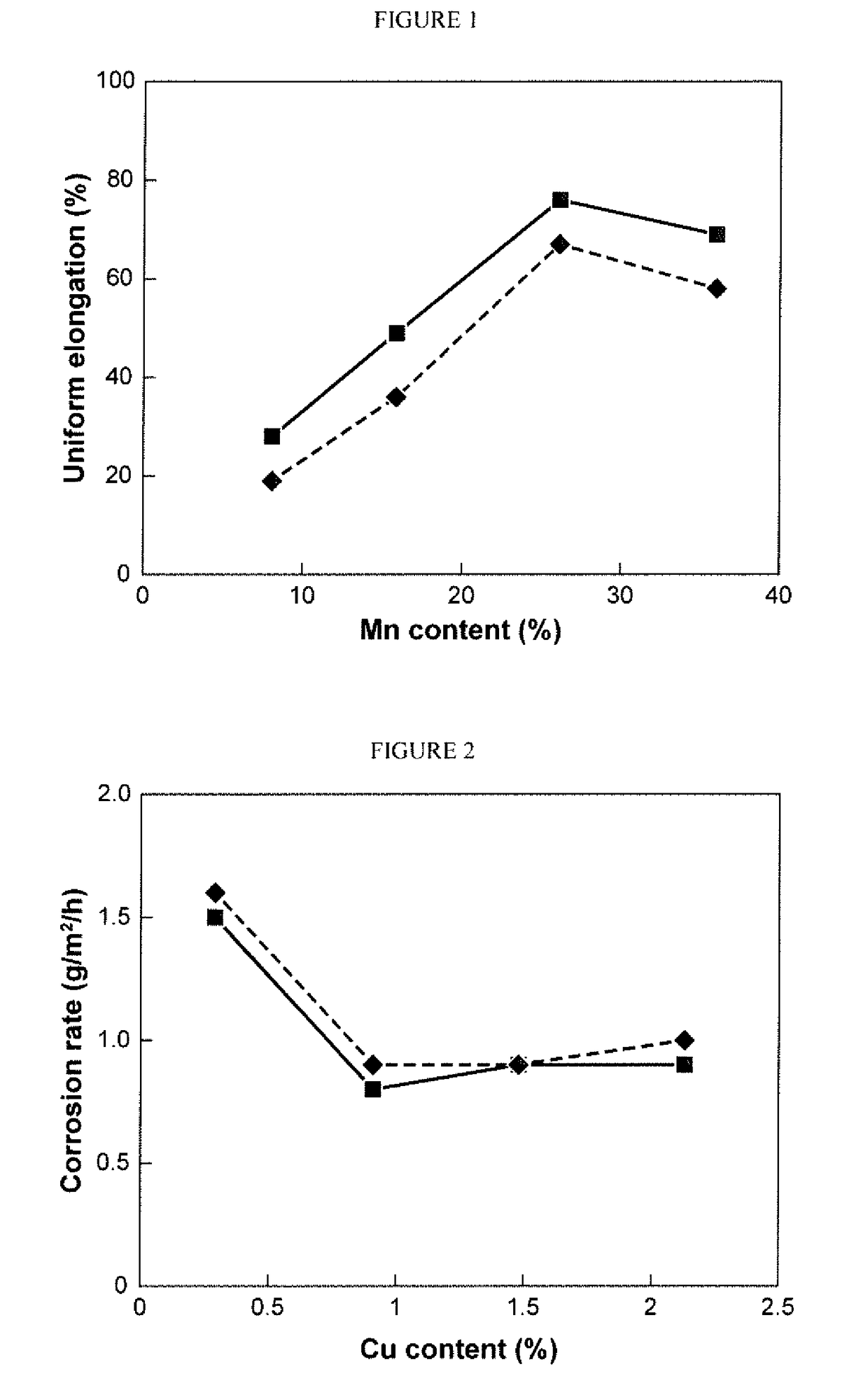

| uniform elongation | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com