Method for preparing nano-twinned copper layer by high-frequency pulse

A technology of nano-twinned copper and high-frequency pulses, applied in the preparation of nano-twinned copper layers, using high-frequency pulses to prepare nano-twinned copper layers, can solve the problem of slow deposition speed, low production efficiency, and maintenance costs of electroforming solutions High-level problems, to achieve fast deposition speed, improve production efficiency, reduce costs and the effect on the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

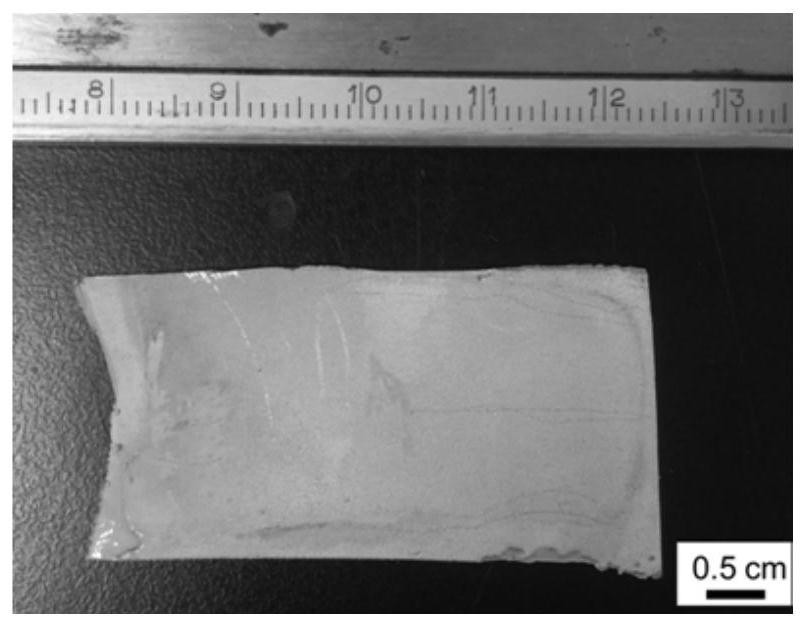

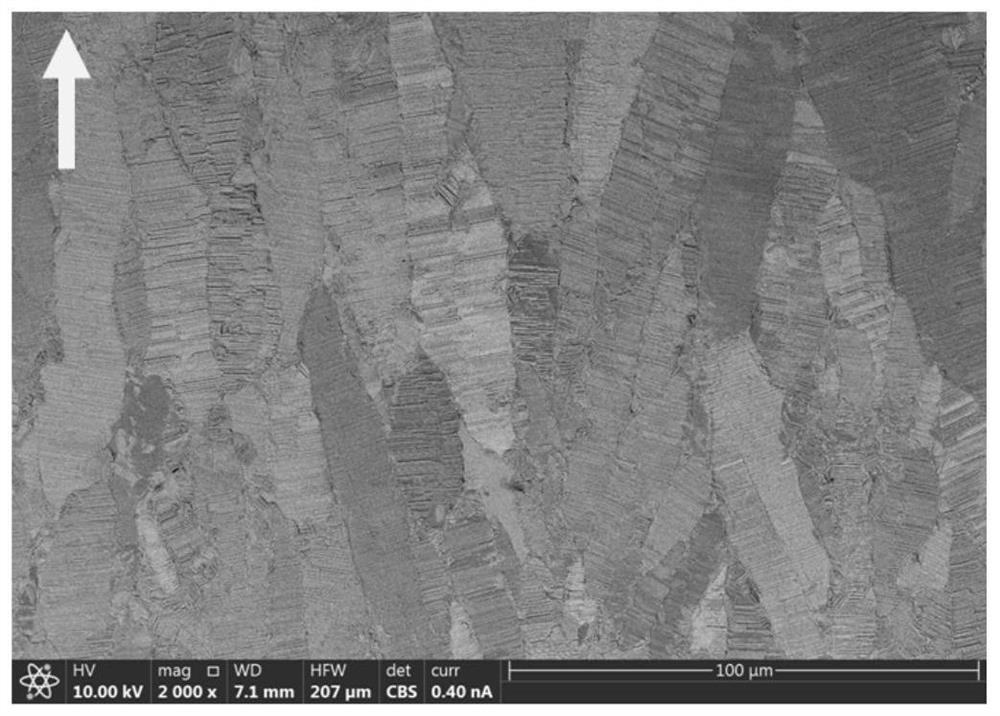

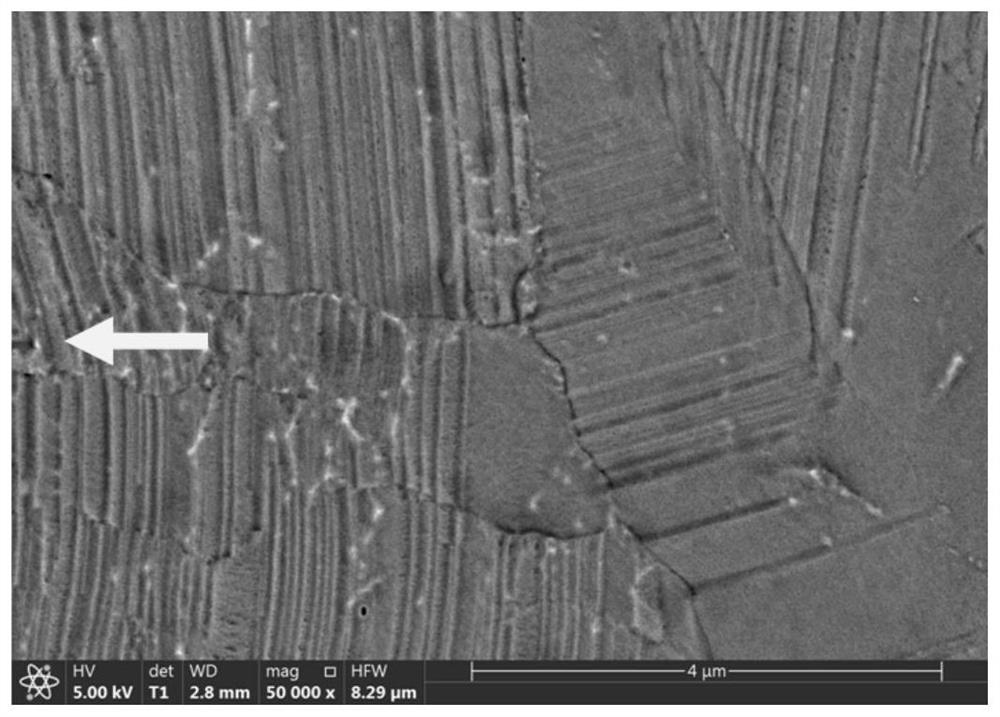

Image

Examples

Embodiment 1

[0027] Step 1: Prepare electroforming copper solution

[0028] Step 101: Add about 700mL of deionized water into a 1L electroforming tank;

[0029] Step 102: Add 25g copper sulfate pentahydrate (CuSO 4 ·5H 2 O) and 100mL volume fraction of 98% sulfuric acid (H 2 SO 4 ), uniformly stirred to obtain an electroforming copper solution; and adding deionized water to the electroforming copper solution until the total volume of the electroforming copper solution was 1L;

[0030] Step 2: Electroforming nano-twinned copper layer

[0031] Step 201: adjusting the temperature of the electroforming copper solution to 30° C., and keeping it constant during the electroforming process;

[0032] Step 202: Place a copper electroforming anode with a purity of 99.98% and a titanium metal cathode to be electroformed with a bright surface in the electroforming solution, adjust the distance between the cathode and the anode to 6 cm, and control the ratio of the areas of the cathode and the anod...

Embodiment 2

[0037] Step 1: Prepare electroforming copper solution

[0038] Step 101: Add about 1500 mL of deionized water into a 2L electroforming tank;

[0039] Step 102: Add 30g copper sulfate pentahydrate (CuSO 4 ·5H 2 O) and 200mL volume fraction of 98% sulfuric acid (H 2 SO 4 ), uniformly stirred to obtain an electroforming copper solution; and adding deionized water to the electroforming copper solution until the total volume of the electroforming copper solution was 2L;

[0040] Step 2: Electroforming nano-twinned copper layer

[0041]Step 201: adjusting the temperature of the electroforming copper solution to 35° C., and keeping it constant during the electroforming process;

[0042] Step 202: Place a copper electroforming anode with a purity of 99.98% and a bright titanium metal cathode to be electroformed in the electroforming solution, adjust the distance between the cathode and the anode to 3 cm, and control the ratio of the areas of the cathode and the anode to 1:5;

[...

Embodiment 3

[0047] Step 1: Prepare electroforming copper solution

[0048] Step 101: Add about 700mL of deionized water into a 1L electroforming tank;

[0049] Step 102: Add 30g copper sulfate pentahydrate (CuSO 4 ·5H 2 O) and 100mL volume fraction of 98% sulfuric acid (H 2 SO 4 ), uniformly stirred to obtain an electroforming copper solution; and adding deionized water to the electroforming copper solution until the total volume of the electroforming copper solution was 1L;

[0050] Step 2: Electroforming nano-twinned copper layer

[0051] Step 201: adjusting the temperature of the electroforming copper solution to 20° C., and keeping it constant during the electroforming process;

[0052] Step 202: Place a copper electroforming anode with a purity of 99.98% and an ABS plastic cathode coated with conductive silver paint to be electroformed in the electroforming solution, adjust the distance between the cathode and the anode to be 8 cm, and control the ratio of the area of the cath...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com