Alpha-ß TITANIUM ALLOY

a titanium alloy and beta-ß technology, applied in the field of titanium alloys, can solve the problems of affecting the expansion of applications, affecting the application range, and the extremely high manufacturing cost of - titanium alloy, and achieves excellent hot workability, excellent machinability, and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0045]The present invention will be more specifically described below by way of Examples, but is not limited to the following Examples. It is obvious that various modifications can be made to these examples as long as they are adaptable to the above-mentioned and below-mentioned concepts and are included within the scope of the present invention.

first example

[0046]Test materials were fabricated in the following way. The titanium alloy with each composition shown in Table 1 below was processed by button arc melting to manufacture an ingot with a size of about 40 mm in diameter×20 mm in height. In any example, the P content was restrained to 0.005% or less; the N content was restrained to 0.05% or less; the S content was restrained to 0.05% or less; and the 0 content was restrained to 0.25% or less. In Table 1, the mark “-” means that the corresponding element was not contained. The ingot was heated to 1,200° C. and subjected to the rough forging at a processing ratio of 2.4, represented by the “original cross-sectional area / cross-sectional area after the hot working”, followed by forging at a processing ratio of 4.4 at 870° C. to perform finish processing. Thereafter, annealing was performed on the forged material by holding it at 750° C. for 12 hours, thereby producing a test material. Note that as shown in Comparative Example 7 of Tabl...

second example

[0067]In the second example, the influence of the Si content, especially, on the machinability were studied. As shown in Table 2, various ingots with different Si contents were manufactured to produce test materials in the same way as that in the first example. In any example, the P content was restrained to 0.005% or less; the N content was restrained to 0.05% or less; the S content was restrained to 0.05% or less; and the 0 content was restrained to 0.25% or less. In Table 2, the mark “-” means that the corresponding element was not contained.

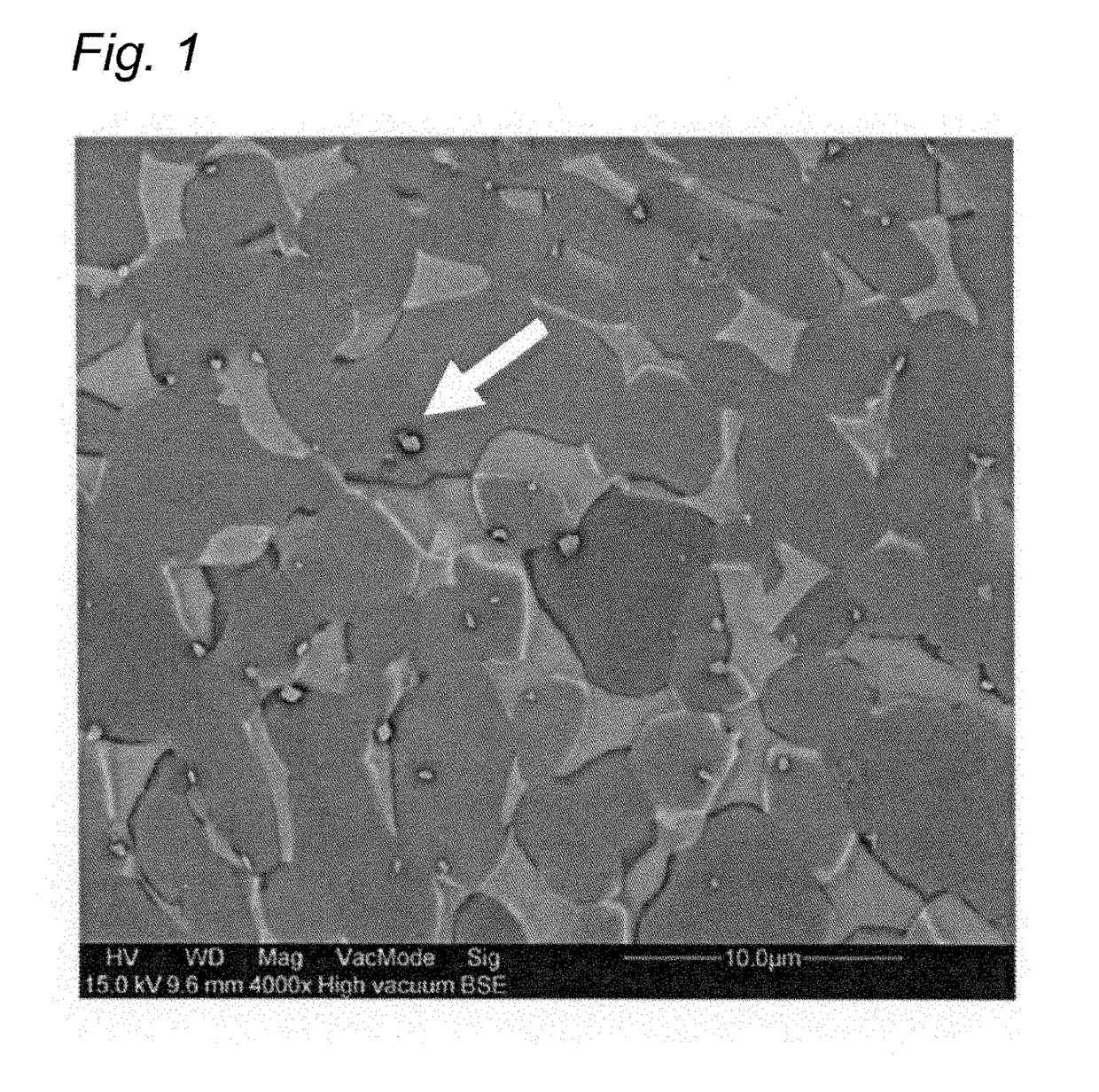

[0068]Each of the above-mentioned test materials was used to confirm the presence or absence of a precipitation phase, as mentioned below, and the Vickers hardness of the test material was measured as an index of strength in the second example. Furthermore, the forgeability of the test material was evaluated in the same way as that in the first example, and the machinability thereof was evaluated as mentioned below. For reference, the tensile...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com