Semiconductor device including barrier layer and manufacturing method thereof

a technology of semiconductor devices and barrier layers, which is applied in the direction of semiconductor devices, electrical devices, transistors, etc., can solve the problems of inferior performance, more complex circuit designs in the new generation, and conventional polysilicon gate faces, so as to improve the electrical performance and electrical performance. the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

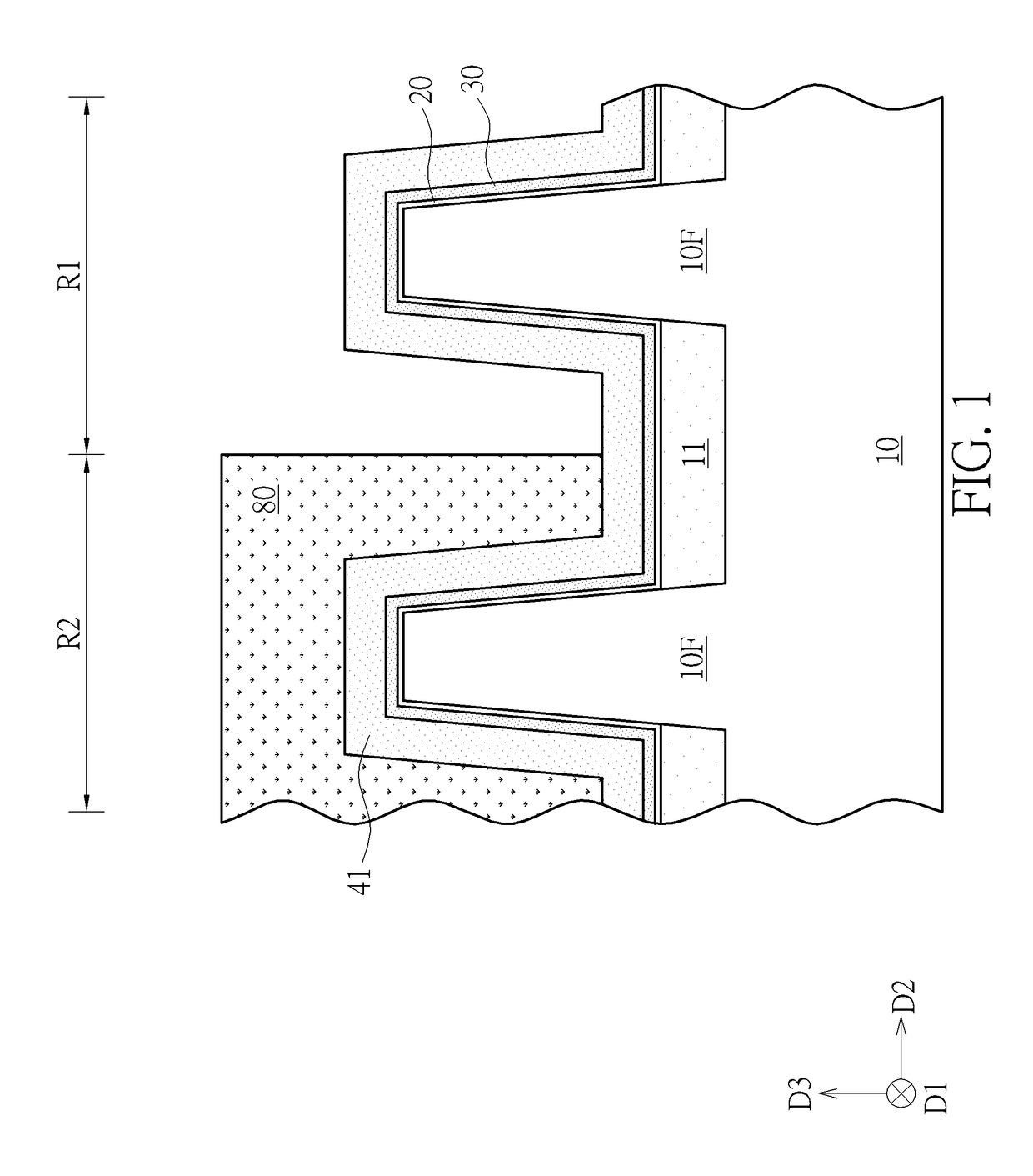

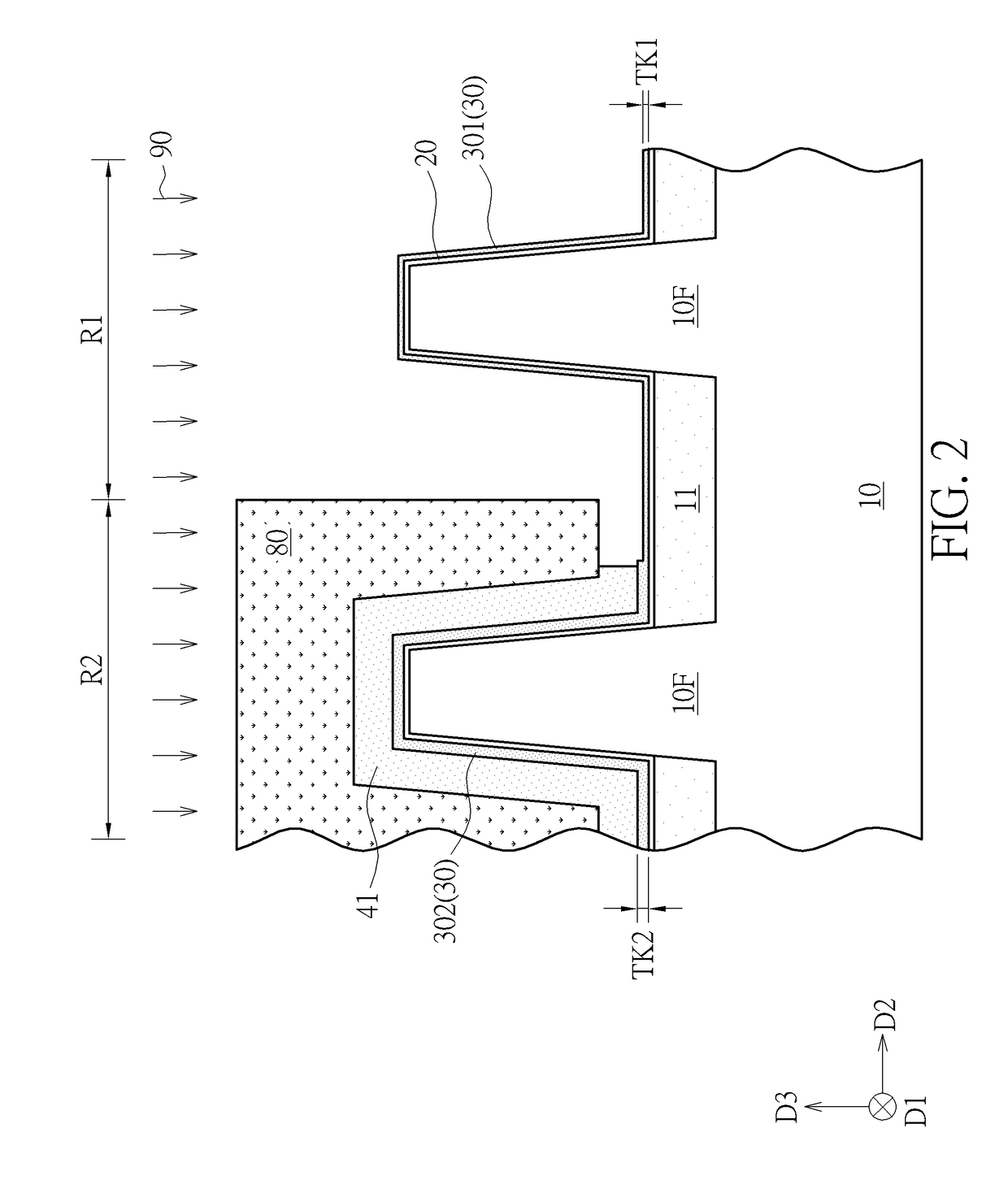

[0025]Please refer to FIG. 1 and FIG. 2. FIG. 1 and FIG. 2 are schematic drawings illustrating a manufacturing method of a semiconductor device according to the present invention. The manufacturing method of the semiconductor device in this embodiment includes the following steps. As shown in FIG. 1, a semiconductor substrate 10 is provided. The semiconductor substrate 10 in this embodiment may include a silicon substrate, an epitaxial silicon substrate, a silicon germanium substrate, a silicon carbide substrate, or a silicon-on-insulator (SOI) substrate, but not limited thereto. The semiconductor substrate 10 includes at least one fin structure 10F, and the fin structure 10F may include a fin structure made of a semiconductor material. In this embodiment, the semiconductor substrate 10 may include a plurality of the fin structures 10F. Each of the fin structures 10F may be elongated in a first direction D1, and the fin structures 10F may be repeatedly disposed in a second direction...

second embodiment

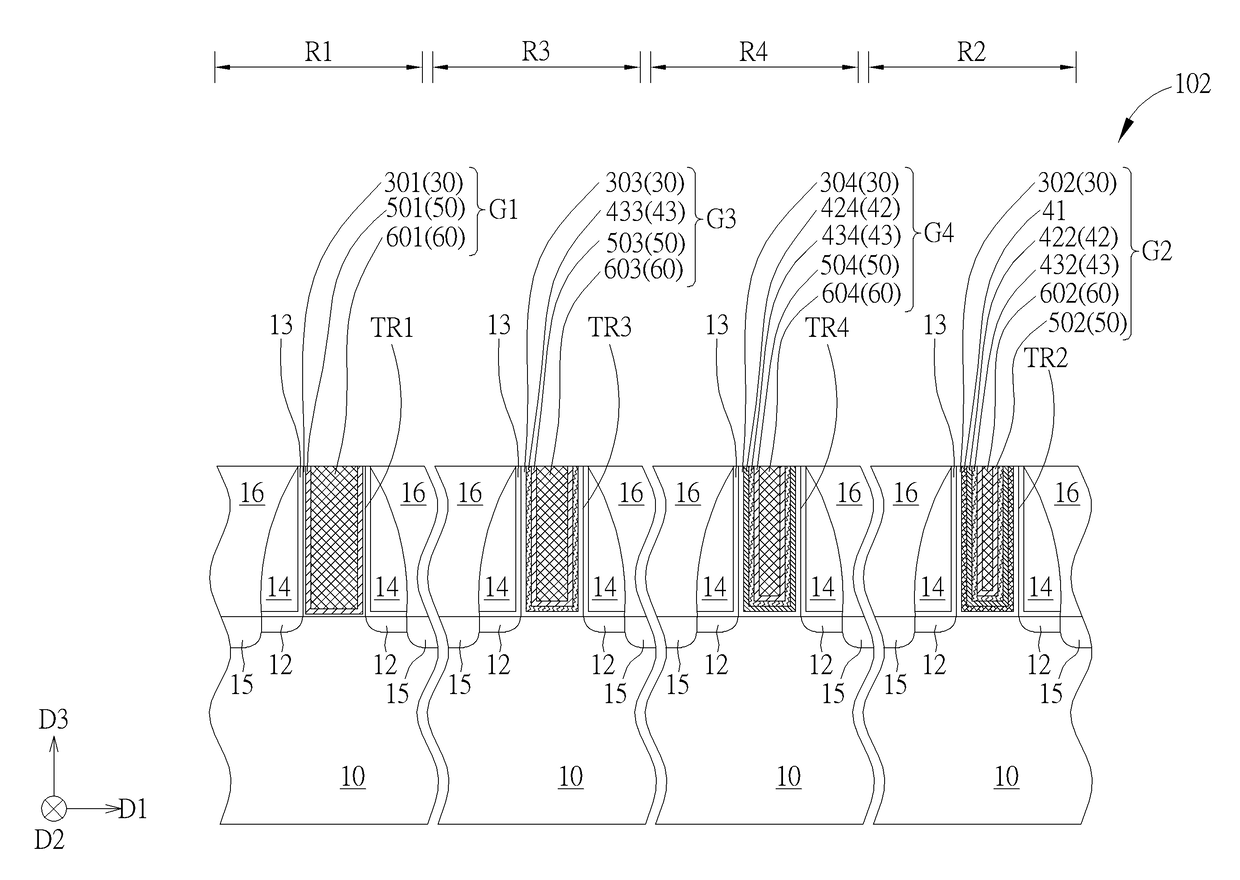

[0028]Please refer to FIGS. 3-7. FIGS. 3-7 are schematic drawings illustrating a manufacturing method of a semiconductor device according to the present invention. The manufacturing method of the semiconductor device in this embodiment includes the following steps. As shown in FIG. 3, the semiconductor substrate 10 is provided. The semiconductor substrate 10 includes the first region R1 and the second region R2 adjacent to the first region R1. The semiconductor substrate 10 may include a plurality of the fin structures 10F. The fin structures 10F are separated from one another by the shallow trench isolation 11. A part of the fin structures 10F may be disposed in the first region R1, and another part of the fin structures 10F may be disposed in the second region R2. The barrier layer 30 is then formed on the semiconductor substrate 10. Before the step of forming the barrier layer 30, the gate dielectric layer 20 may be conformally formed on the fin structures 10F and the shallow tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com