Cosmetic composition having high dosage form stability

a formulation and stability technology, applied in the field of cosmetic compositions, can solve the problems of degrading the absorption or texture of skin products, affecting the stability of cosmetic compositions, and affecting the use quality of products, so as to improve the stability of dosage forms, prevent the effect of reducing the texture of use, and improve the quality of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

experimental example 1

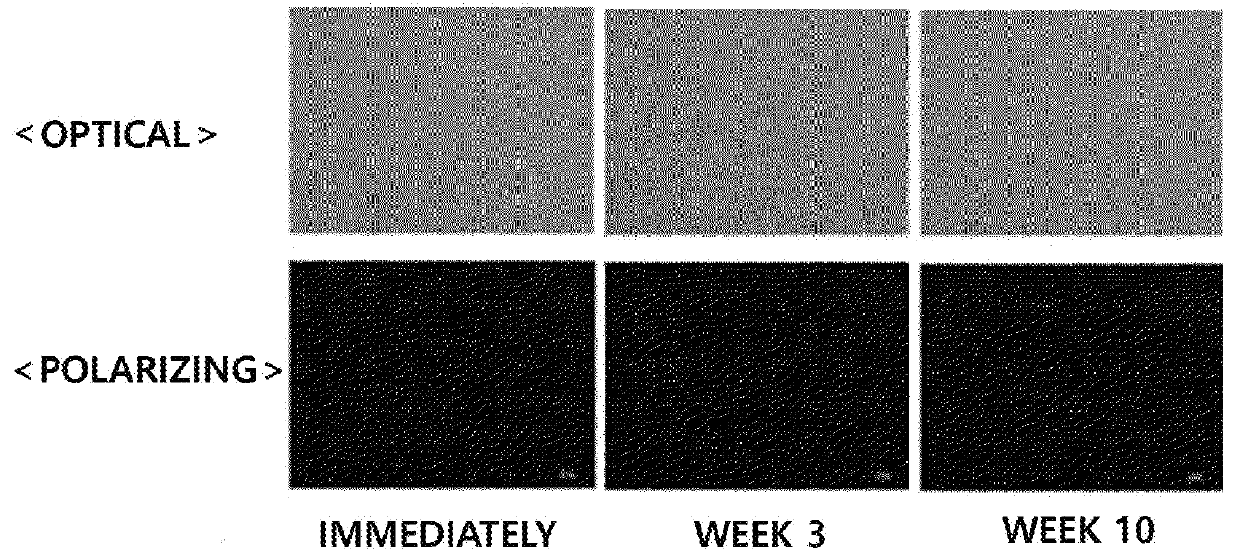

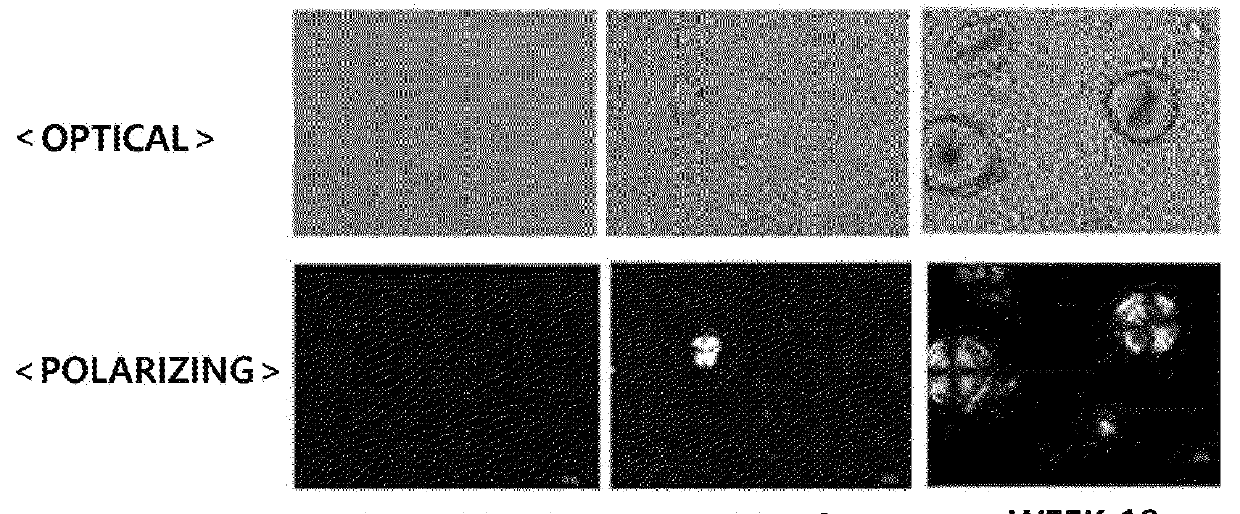

Precipitation Test Depending on Types of Stabilizers

[0071](1) Preparation of Emulsion Composition for Skin Care

[0072]Emulsions for skin care were prepared using the compositions presented in the following Table 1. First, components 1 to 4 were mixed, and dissolved at 70° C. to prepare an aqueous phase. Thereafter, components 5 to 11 were dissolved at 70° C. to prepare an oily phase. Subsequently, the oily phase was added to the aqueous phase, and primarily emulsified while stirring using a homomixer. Then, component 12 was added thereto to increase a viscosity of the mixture. Finally, bubbles were removed, components 13 and 14 were added thereto, and the resulting mixture was then cooled to prepare an emulsion composition. In this case, SurfMellow BBG (manufactured by Toyobo Co., Ltd.) was used as the MEL.

TABLE 1ExampleComparativeComparativeComparativeComparativeComparativeComponents (% by weight)1Example 1Example 2Example 3Example 4Example 5Aqueous phase1. Purified waterUp to 100Up...

experimental example 2

Precipitation Test Depending on Content of MEL

[0086]To check the optimal content of the MEL used as the stabilizer, emulsion compositions were prepared in the same manner as in the composition of Example 1, and precipitation tests were performed on the emulsion compositions. In this case, the content of the component was adjusted to 100% by weight by varying the content of purified water.

TABLE 3ItemsNo. 1No. 2No. 3No. 4No. 5No. 6No. 7ComponentsKojyl0.10.10.10.10.10.10.1(% by weight)methylenedioxycinnamateMEL00.250.50.7511.251.5PrecipitationImmediately afterXXXXXXXtestpreparationWeek 3◯XXXXXXWeek 10⊚▴XXXXX

[0087]Referring to Table 3, it can be seen that the crystallization of the kojyl methylenedioxycinnamate was inhibited only when the MEL was added at a content of 0.25% by weight or more, based on the total weight of the cosmetic composition. Particularly, it can be seen that the dosage form stability was maintained after 10 weeks of the preparation only when the MEL was added at a ...

experimental example 3

Precipitation Test Depending on Content Ratios of Kojyl Methylenedioxycinnamate And MEL

[0089]To check whether the crystallization occurred according to the content ratios of the kojyl methylenedioxycinnamate and MEL, emulsion compositions were prepared in the same manner as in the composition of Example 1, and precipitation tests were performed on the emulsion compositions. In this case, the content of the component was adjusted to 100% by weight by varying the content of purified water.

TABLE 4ItemsNo. 8No. 9No. 10No. 11No. 12No. 13ComponentsKojyl0.10.050.10.150.20.25(% by weight)methylenedioxycinnamateMEL00.50.50.5 0.50.5Content ratio—1:101:51:3.31:2.51:2PrecipitationImmediately afterXXXXXXtestpreparationWeek 3XXXXXXWeek 10XXXX▴▴

[0090]Referring to Table 4, it was confirmed that, when the MEL was added, the crystallization did not occur on week 3, and the crystals were observed in the tests performed on the compositions (Nos. 12 and 13) after 10 weeks of the preparation.

[0091]From t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical micelle concentration | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com