Method for producing solid urea by granulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

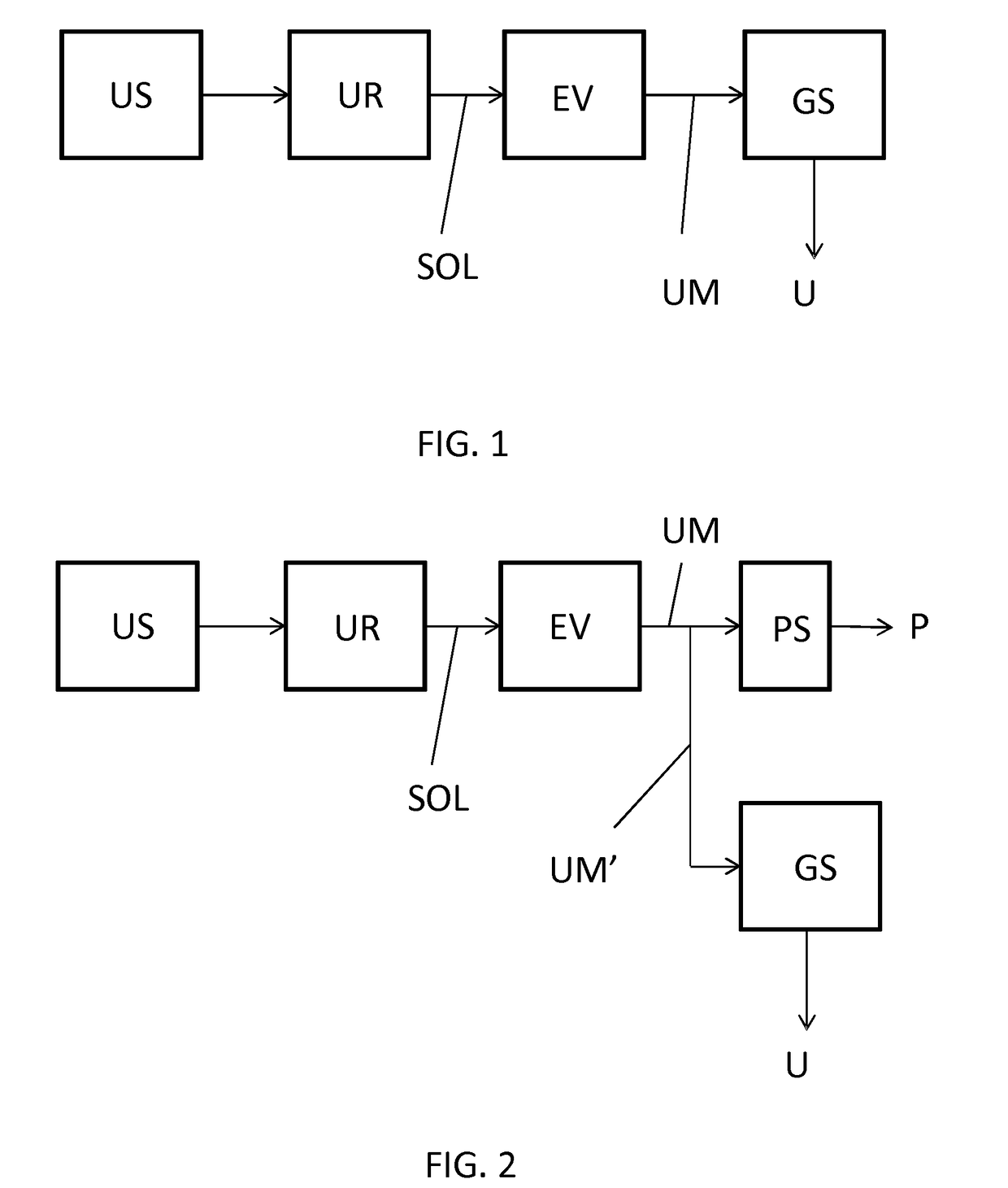

[0028]FIG. 1 shows a schematic urea plant comprising a synthesis section US and a recycling section UR. The recycling section UR provides an aqueous solution of urea SOL containing about 70% by weight of urea.

[0029]Said solution passes through evaporation section EV inside which the water is removed, obtaining a urea melt UM containing more than 98%, for example 99.7%, by weight of urea. Said urea melt UM, without the addition of formaldehyde, is fed to a granulation section GS, obtaining granules of urea U.

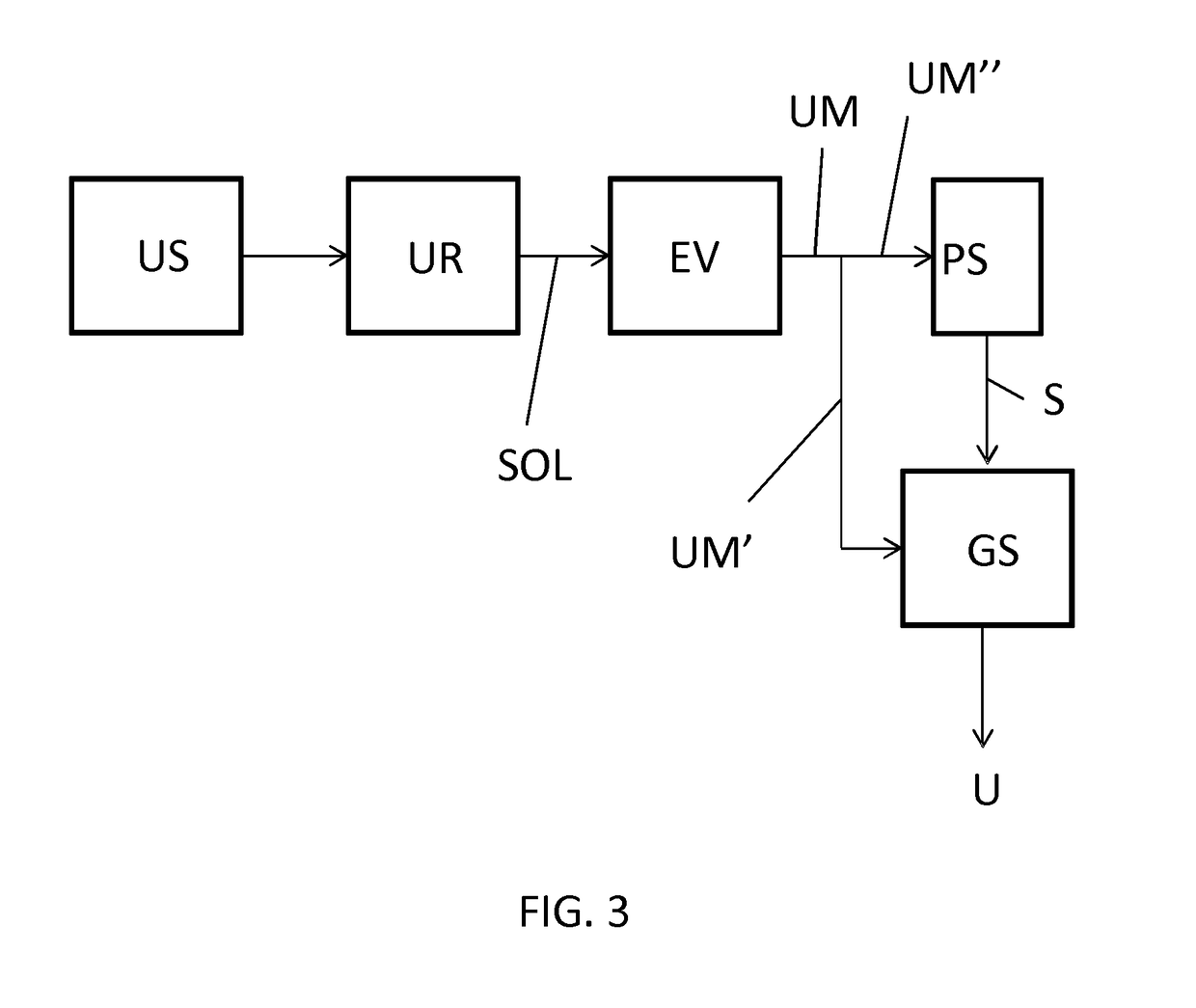

[0030]FIG. 2 shows an example of revamping of a plant in which the urea melt UM is originally fed to a prilling section PS which produces urea prills P. At least a part UM′ of said urea melt UM is fed to a granulation section GS which is arranged parallel to the prilling section PS, also in this case without the addition of formaldehyde.

[0031]In some embodiments, the UM stream is directed entirely towards the new granulation section GS, i.e. the production of prills P is disconti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com