Spring tube type flexible micro chemical reactor

a flexible micro chemical reactor and spring tube technology, applied in chemical/physical/physical-chemical stationary reactors, chemical apparatus and processes, chemical/physical/physical-chemical processes, etc., can solve the problems of poor heat transfer capability of the fluid itself, high machining cost, and complex machining technology, so as to enhance the mixing effect, enhance the mass and heat transfer, and enhance the effect of mass and heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]The present invention is further described with reference to the accompanying drawings and specific embodiment.

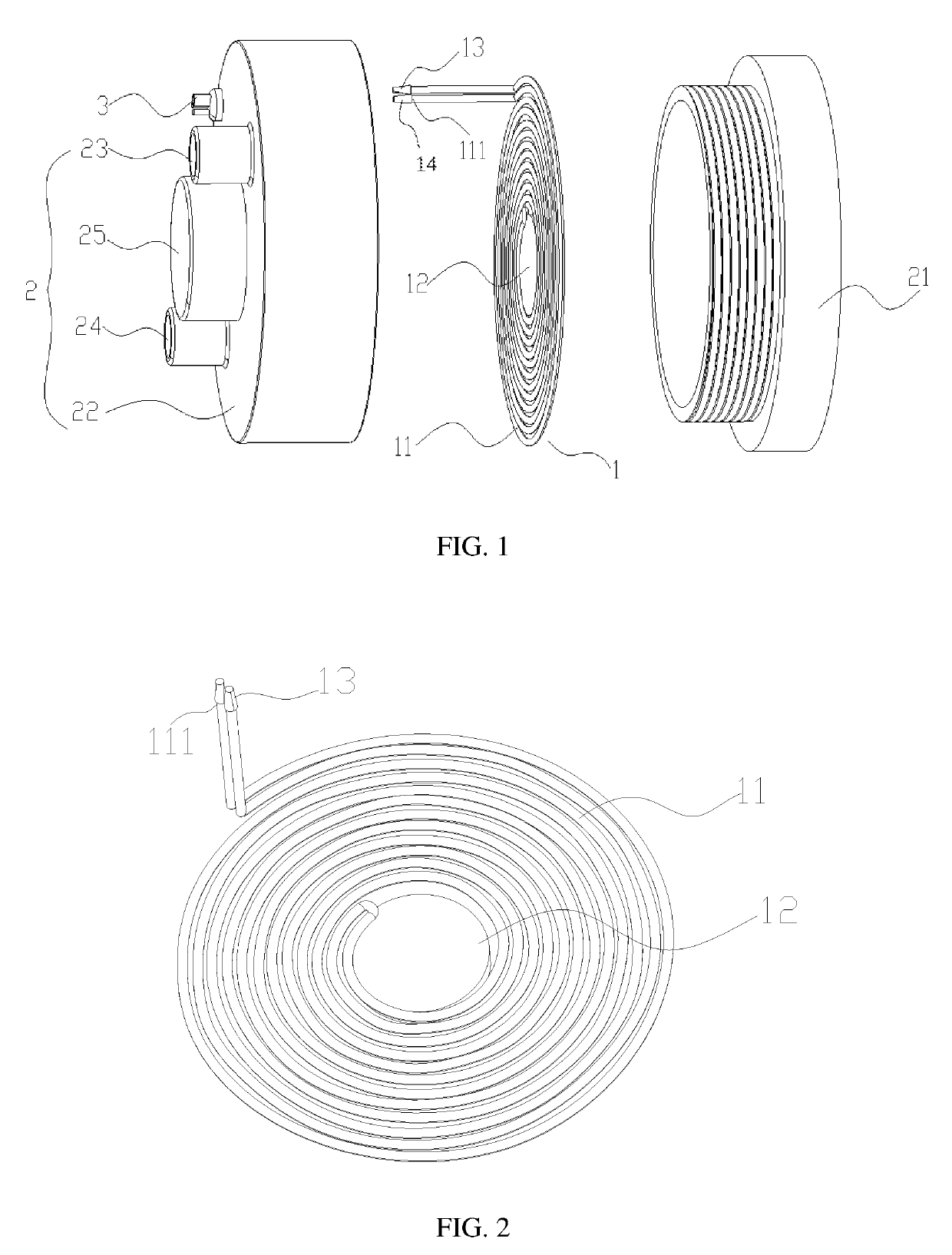

[0033]As shown in FIGS. 1-7, a spring tube type flexible micro chemical reactor according to the present invention, which comprises a reactor body 1 for performing a micro chemical reaction, a thermal control device 2 equipped with a heat transfer medium, and a gas generating device for supplying a gas to the reaction body (FIG. 7).

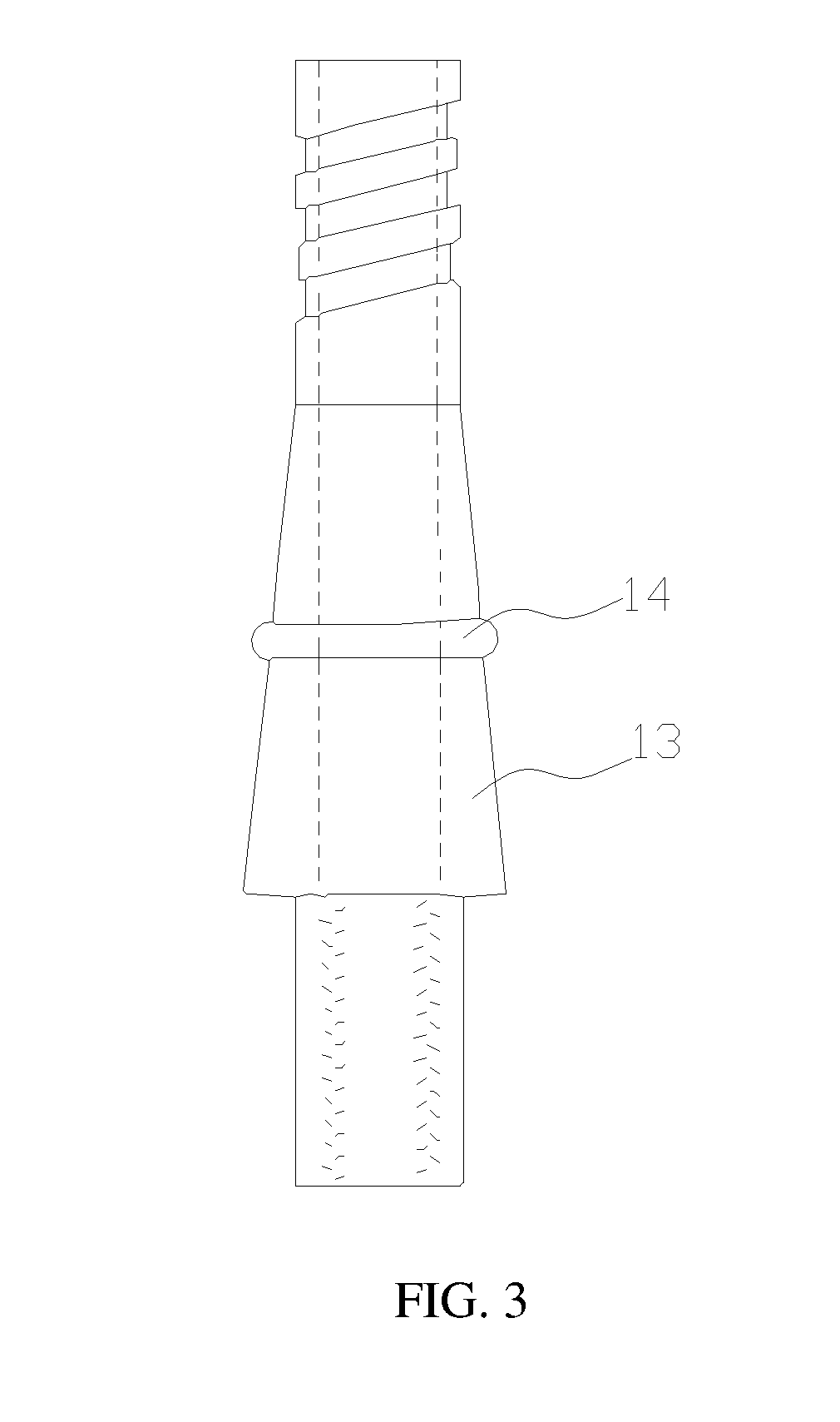

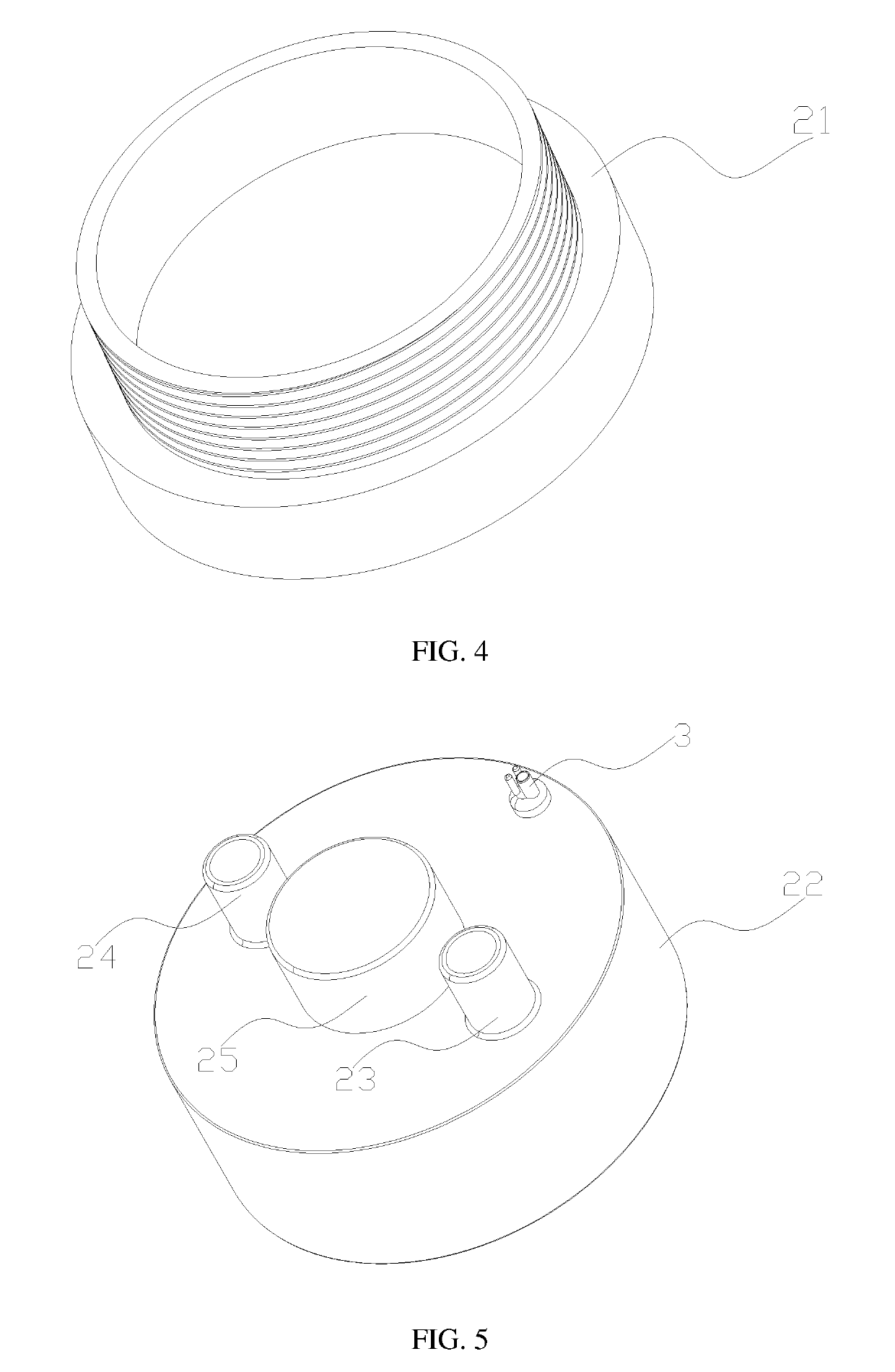

[0034]The reactor body 1 comprises a permanent magnet 12 and a scroll spring tube 11 having an access interface 111. The scroll spring tube 11 is fixed inside the thermal control device 2 via angle iron, and the heat and the mass transfer effect is enhanced by the micro tube of the scroll spring tube 11. The scroll spring tube 11 is a hollow structure and has a vortex-like or spiral shape as a whole so as to achieve a compact structure. At the same time, a secondary flow is generated by using a vortex-like or a spiral structure to enhance t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com