Process for the production of hydrocarbon biofuels

- Summary

- Abstract

- Description

- Claims

- Application Information

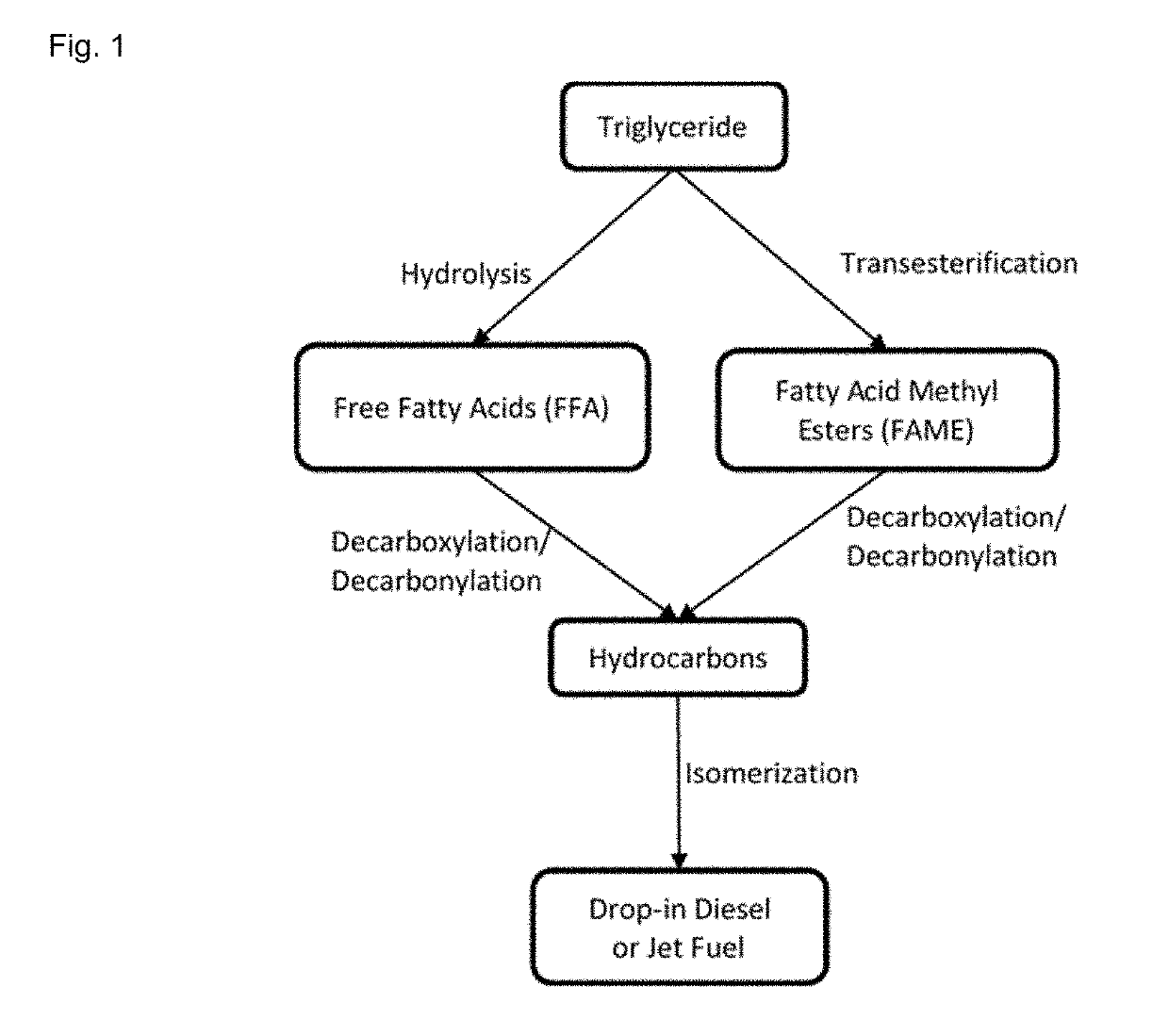

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

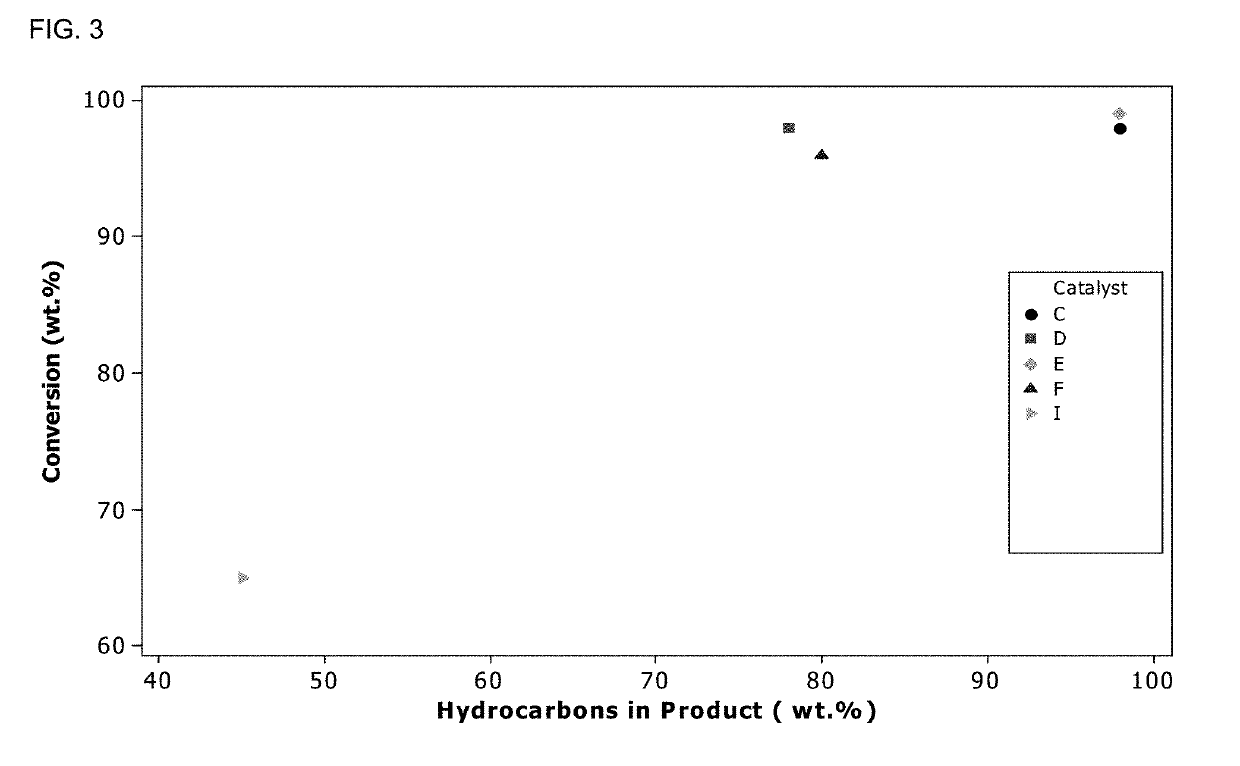

[0030]In one aspect, the present invention provides a method of deoxygenating a feedstock, comprising at least one oxygenated organic compound, to form a hydrocarbon product, comprising the steps of contacting the feedstock with a catalyst under conditions to promote deoxygenation of the at least one oxygenated compound.

[0031]In one aspect, the catalyst comprises a mixed metal oxide of the empirical formula:

(M2)y(M1)O—ZnO—(Al2O3)x

wherein M1 is a metal selected from the group consisting of Ag, Au, Co, Cr, Cu, Fe, Ir, Mo, Ni, Os, Pd, Pt, Rh, Ru, and W; M2 is a metal selected from the group consisting of Ag, Au, Co, Cr, Cu, Fe, Ir, Mo, Ni, Os, Pd, Pt, Rh, Ru, and W, but is not the same as M1; x is 0 or 1; and y is 0 or 1.

[0032]In one aspect, M1 is selected from the group consisting of Co and Ni. In one aspect, M2 is selected from the group consisting of Ag, Au, Co, Ir, Ni, Os, Pd, Pt, Rh, and Ru.

[0033]In one aspect, the catalyst comprises a mixed metal oxide of the formula MO—ZnO—(Al2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com