Methods and apparatus for treating bitumen mixtures

a bitumen mixture and treatment method technology, applied in the direction of working up pitch/asphalt/bitumen by selective extraction, working up pitch/asphalt/bitumen by mixing fractions, adhesive types, etc., can solve the problem of lack of specific combinations of steps and features in prior methods and apparatus, and achieve the desired initial boiling point (ibp), avoid acid corrosion attacks, advantageously avoid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

1. Introduction

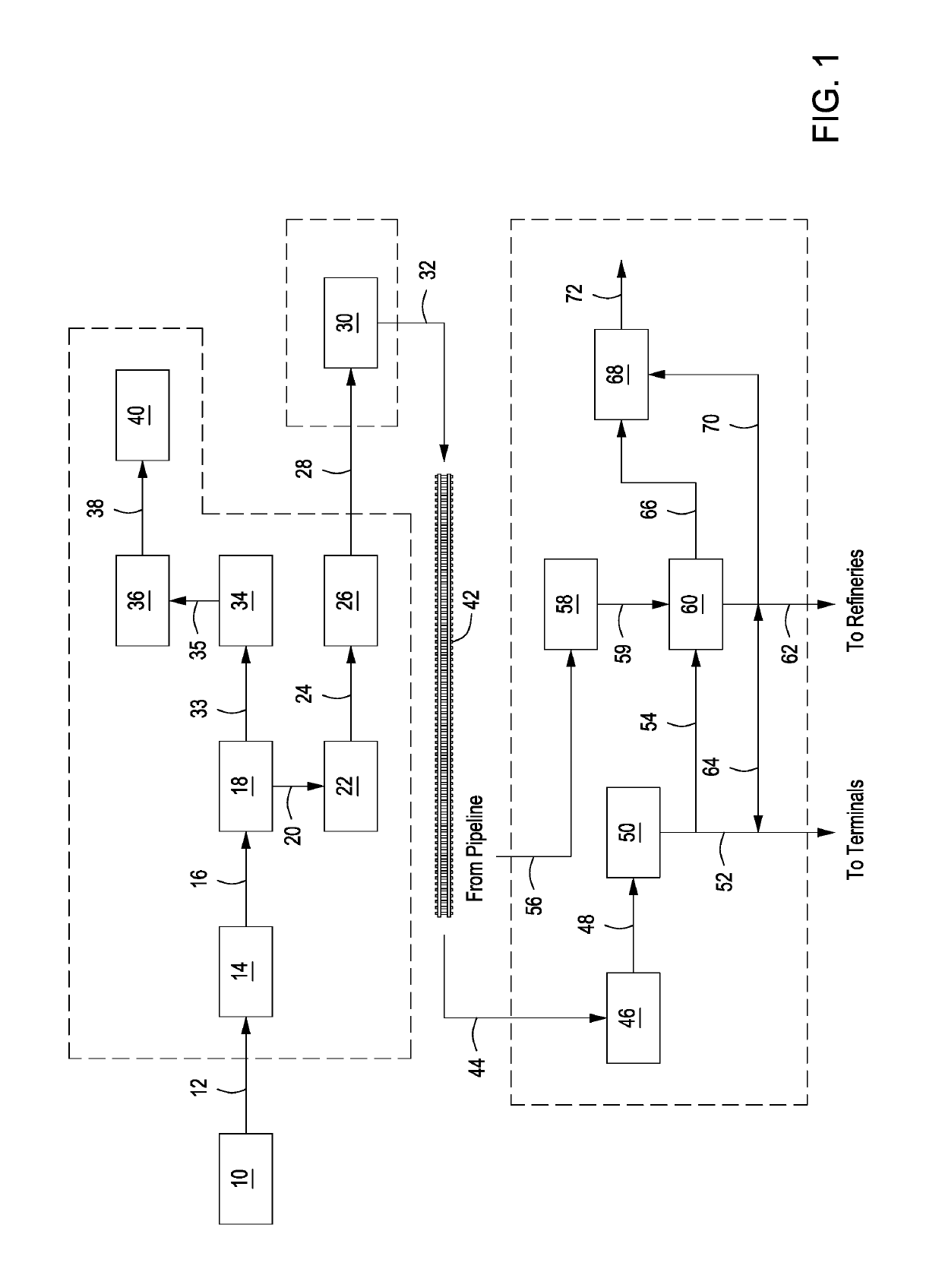

[0045]A detailed description will now be provided. The purpose of this detailed description, which includes the drawings, is to satisfy the statutory requirements of 35 U.S.C. § 112. For example, the detailed description includes a description of the inventions and sufficient information that would enable a person having ordinary skill in the art to make and use the inventions defined by the claims. In the figures, like elements are generally indicated by like reference numerals regardless of the view or figure in which the elements appear. The figures are intended to assist the description and to provide a visual representation of certain aspects of the subject matter described herein. The figures are not drawn to scale, nor do they show all the structural details of the systems, nor do they limit the scope of the claims.

[0046]Any claim that is included in this or a subsequent application or resulting patent defines a separate invention which, for infringement purpos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com